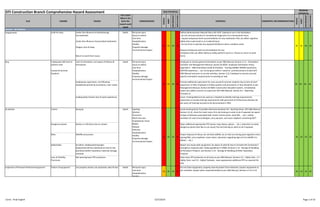

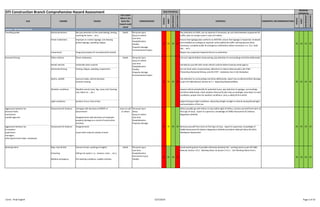

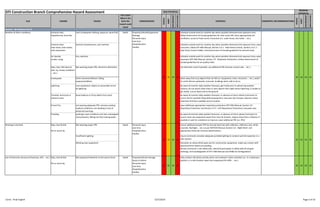

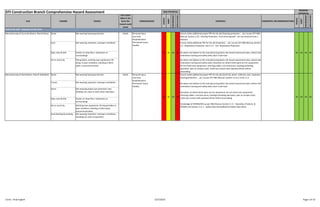

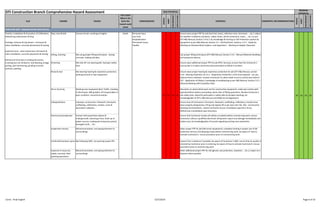

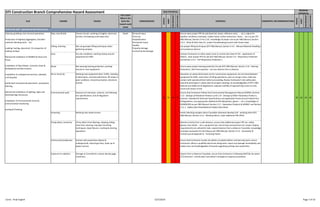

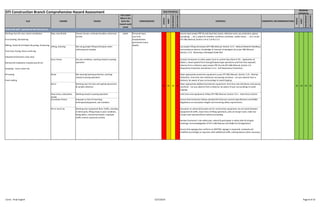

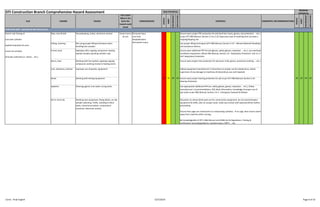

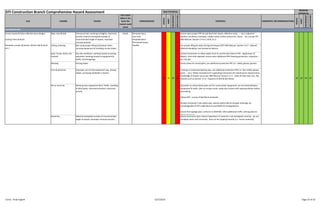

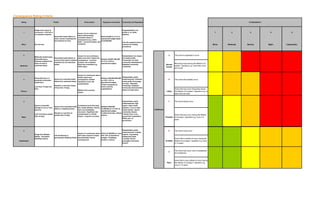

This document provides a hazard assessment for the Construction Branch of the Department of Transportation and Infrastructure. It identifies various tasks and their associated hazards, consequences, controls, and recommendations. Hazards are grouped by topics like general positions, personal driving, weather conditions, working in the dark, and office work. Specific hazards addressed include impairment, distracted driving, aggressive behaviors, extreme temperatures, flooding, ergonomics, chemicals and more. Controls include following policies, training, use of personal protective equipment, limiting exposure times, and conducting safety inspections. The assessment aims to minimize risks and residual risks for people, assets, the environment and the organization's reputation.