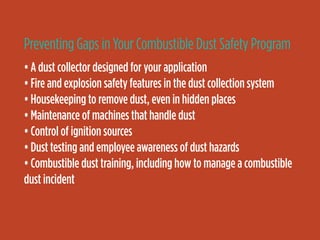

The document by Imperial Systems, Inc. emphasizes the importance of combustible dust safety programs to prevent catastrophic accidents, highlighting lessons learned from three incidents that resulted in multiple fatalities. Key takeaways include the need for effective hazard assessment during process changes, proper dust management, and employee awareness of combustible dust risks. The document advocates for comprehensive dust hazard analyses to prevent historical mistakes from repeating.