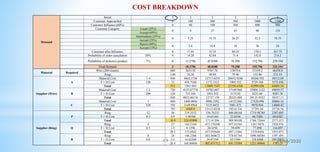

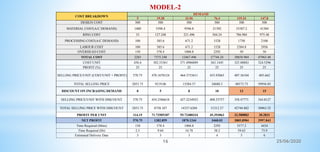

The document presents a collaborative manufacturing platform designed for Industry 4.0, focusing on digital integration of business and manufacturing processes to achieve mass customization. Key objectives include establishing a real-time decision-making system, leveraging technologies like IoT and cloud computing, and analyzing costs associated with production. The literature survey highlights various frameworks and challenges in adopting Industry 4.0, emphasizing the need for smarter manufacturing systems that integrate diverse industry dimensions.