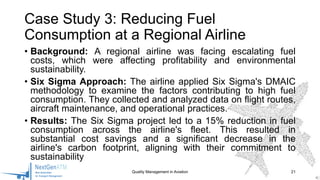

This document discusses quality management in aviation. It introduces concepts like total quality management (TQM) and Six Sigma. TQM emphasizes continuous improvement, customer focus, and employee involvement. Six Sigma is a data-driven methodology used in aviation to reduce defects and streamline processes. The document provides examples of how major airlines like Southwest, Emirates, and Delta have successfully implemented these quality management approaches to improve safety, efficiency, and customer satisfaction. Case studies demonstrate how Six Sigma has been used to enhance on-time performance, maintenance safety, and reduce fuel consumption.