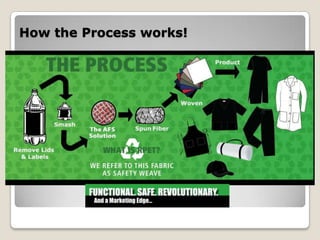

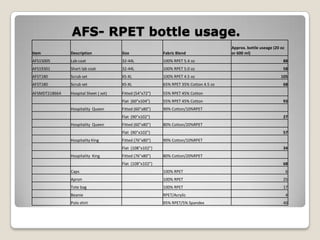

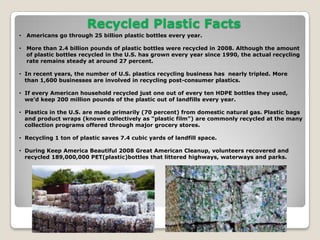

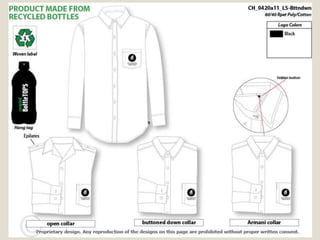

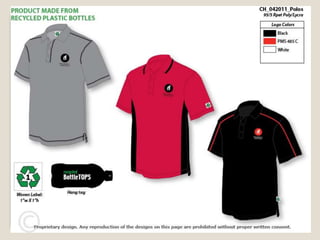

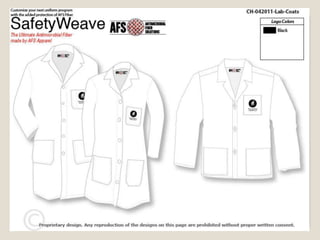

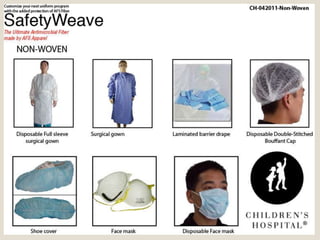

AFS is an innovative company that produces antimicrobial fabrics using a patented process to embed antimicrobial agents into recycled plastic fibers during production. This ensures the antimicrobial properties are not washed out and provides effective elimination of 99.9% of harmful bacteria and germs. AFS can produce customized products like towels, linens and scrubs from these fibers for use in healthcare, hospitality and other industries to promote hygiene and sustainability.