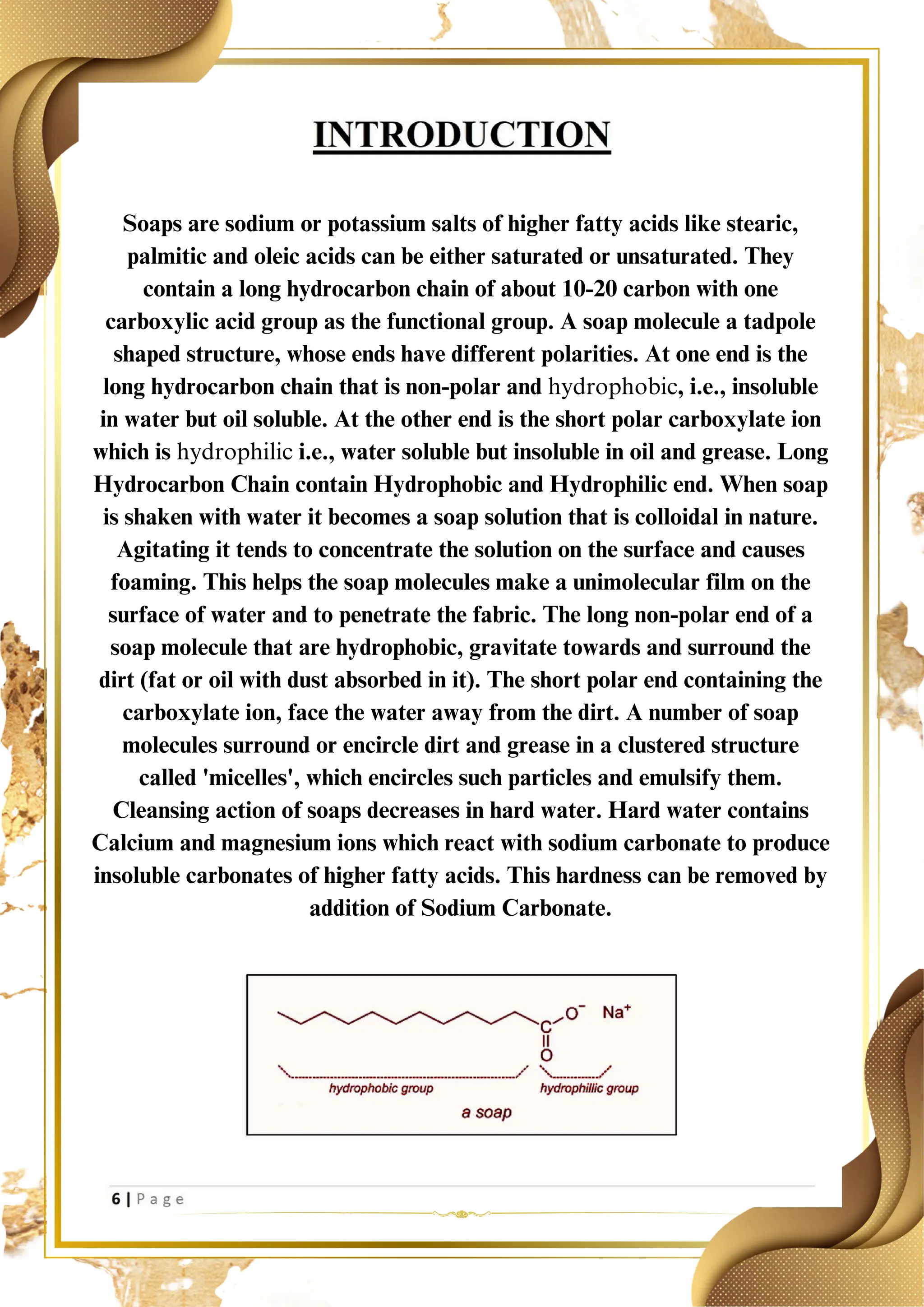

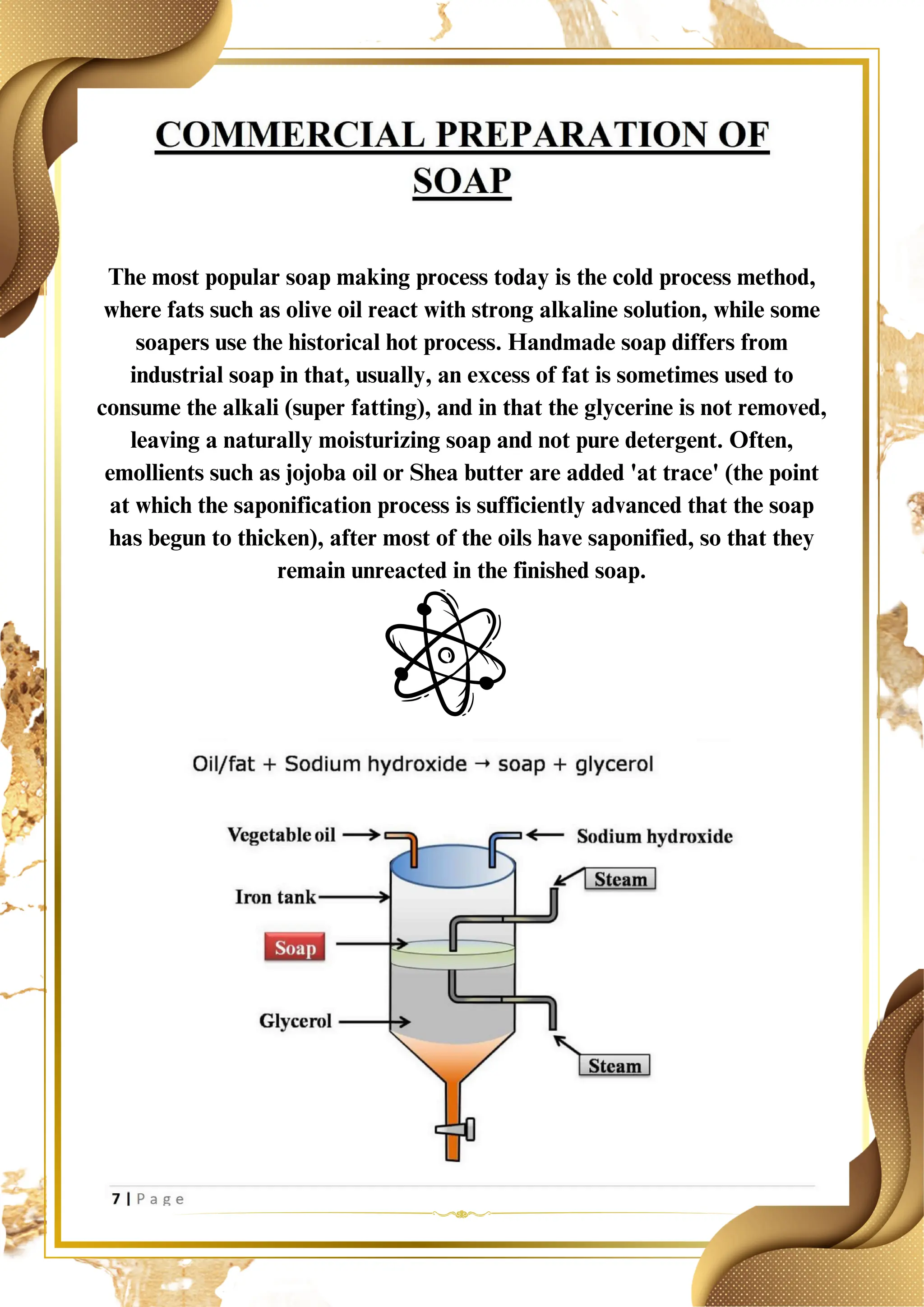

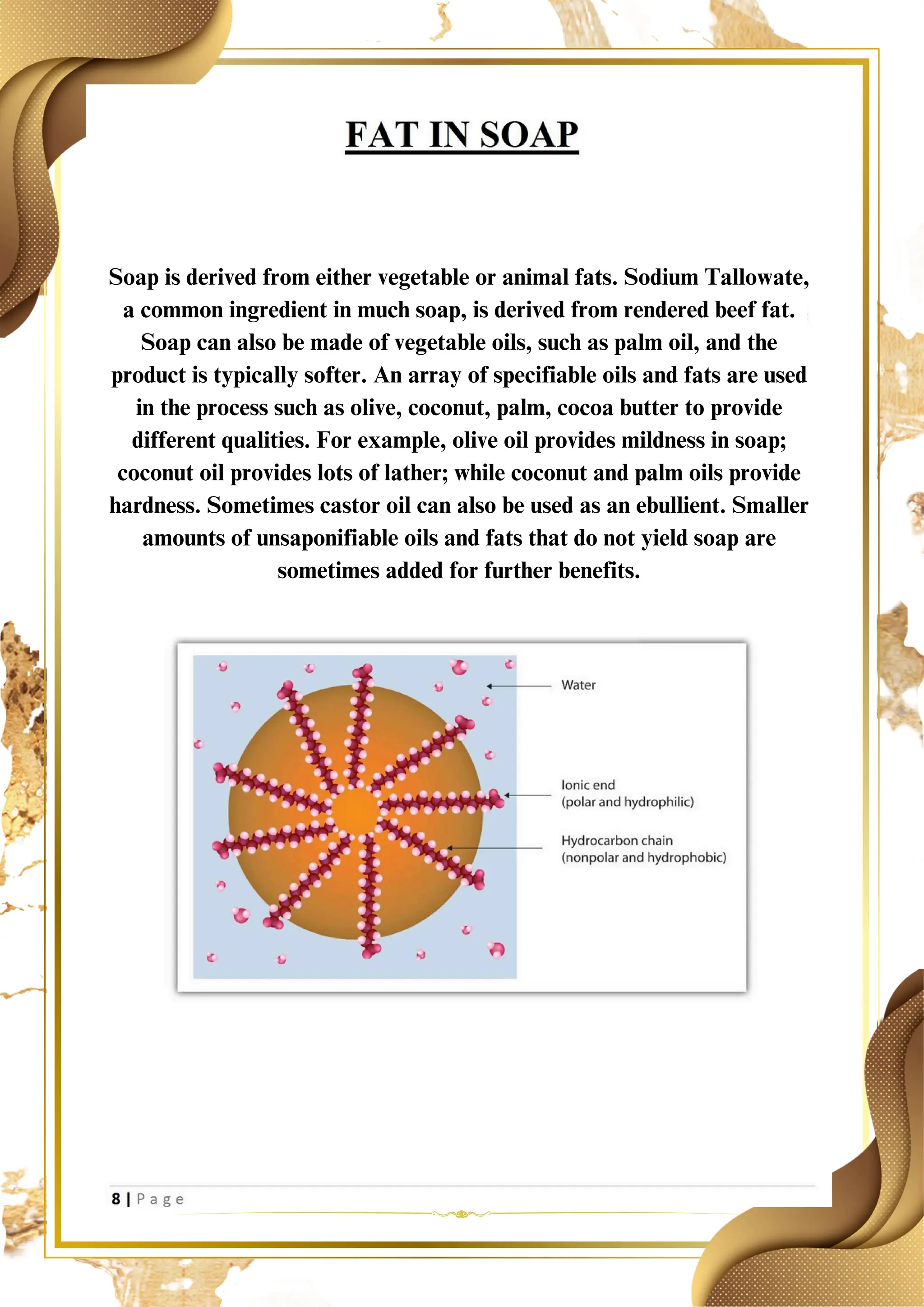

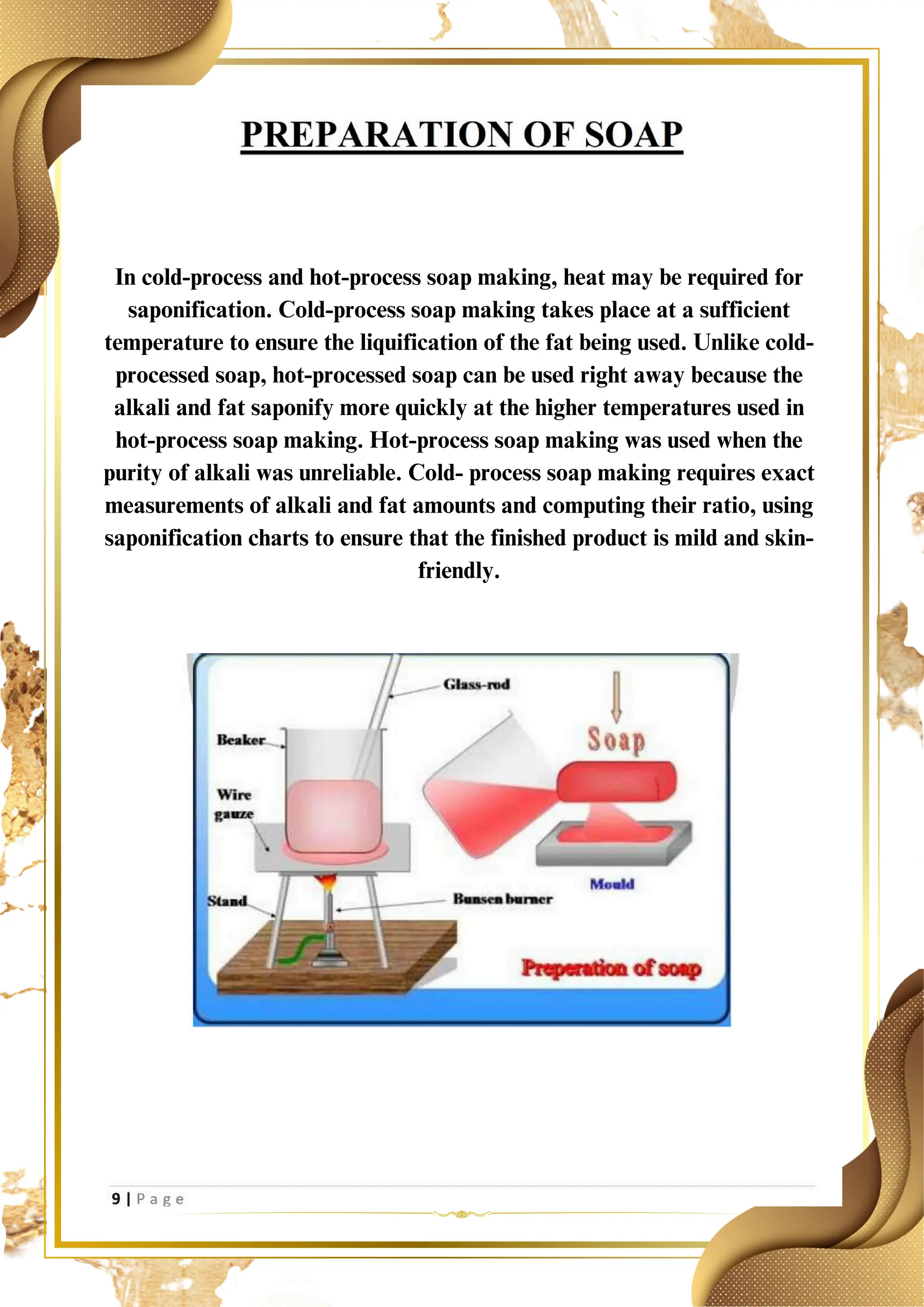

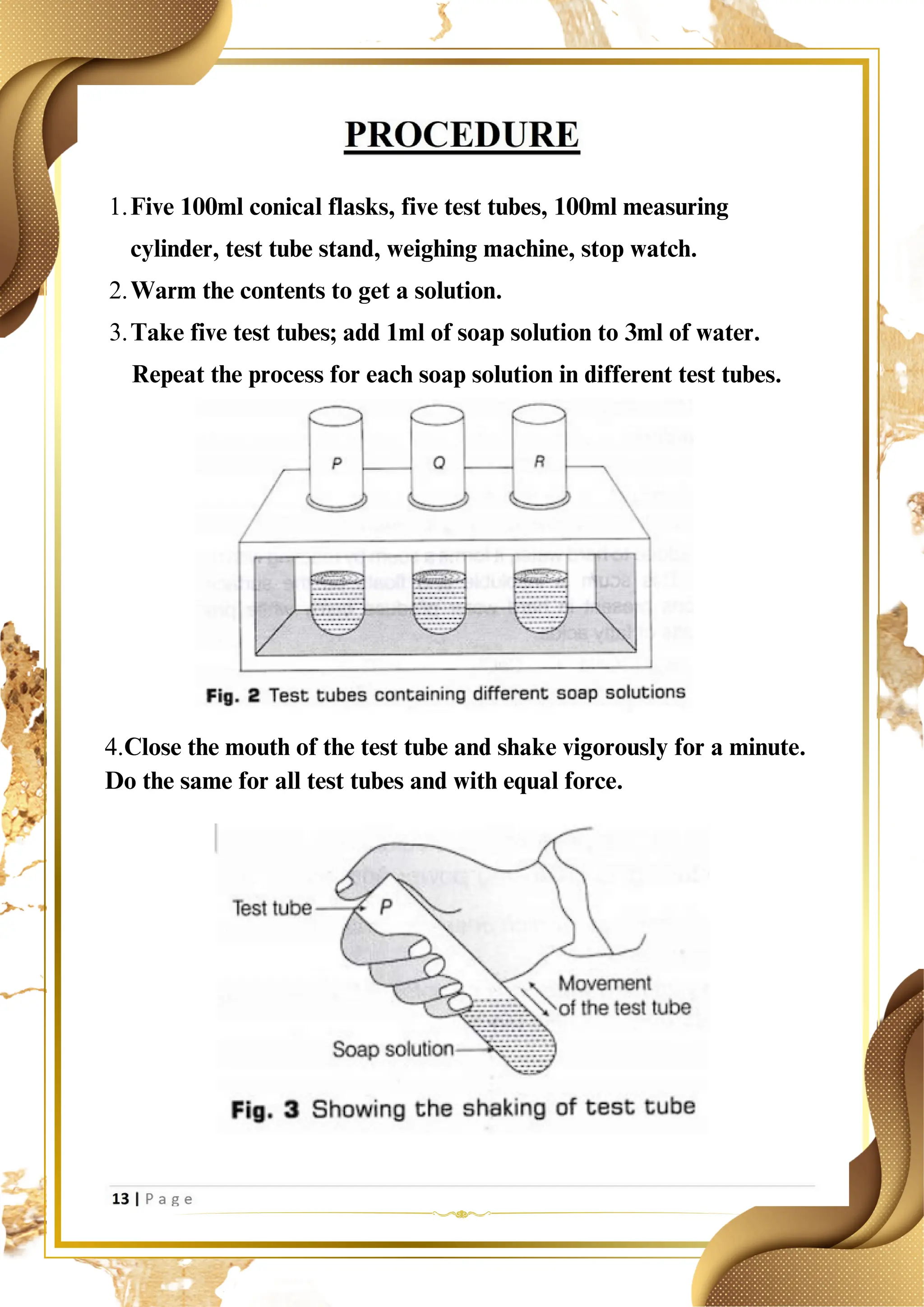

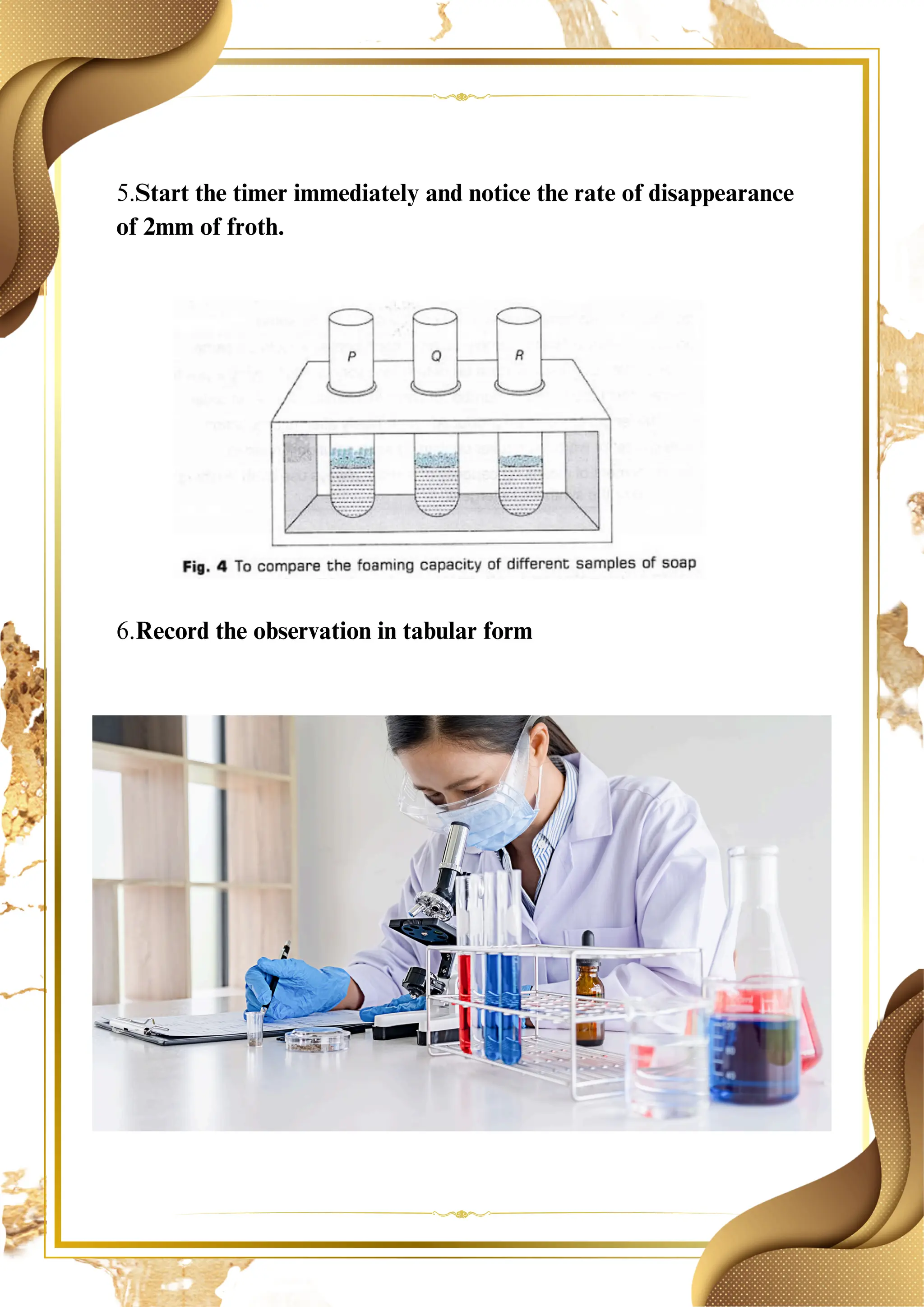

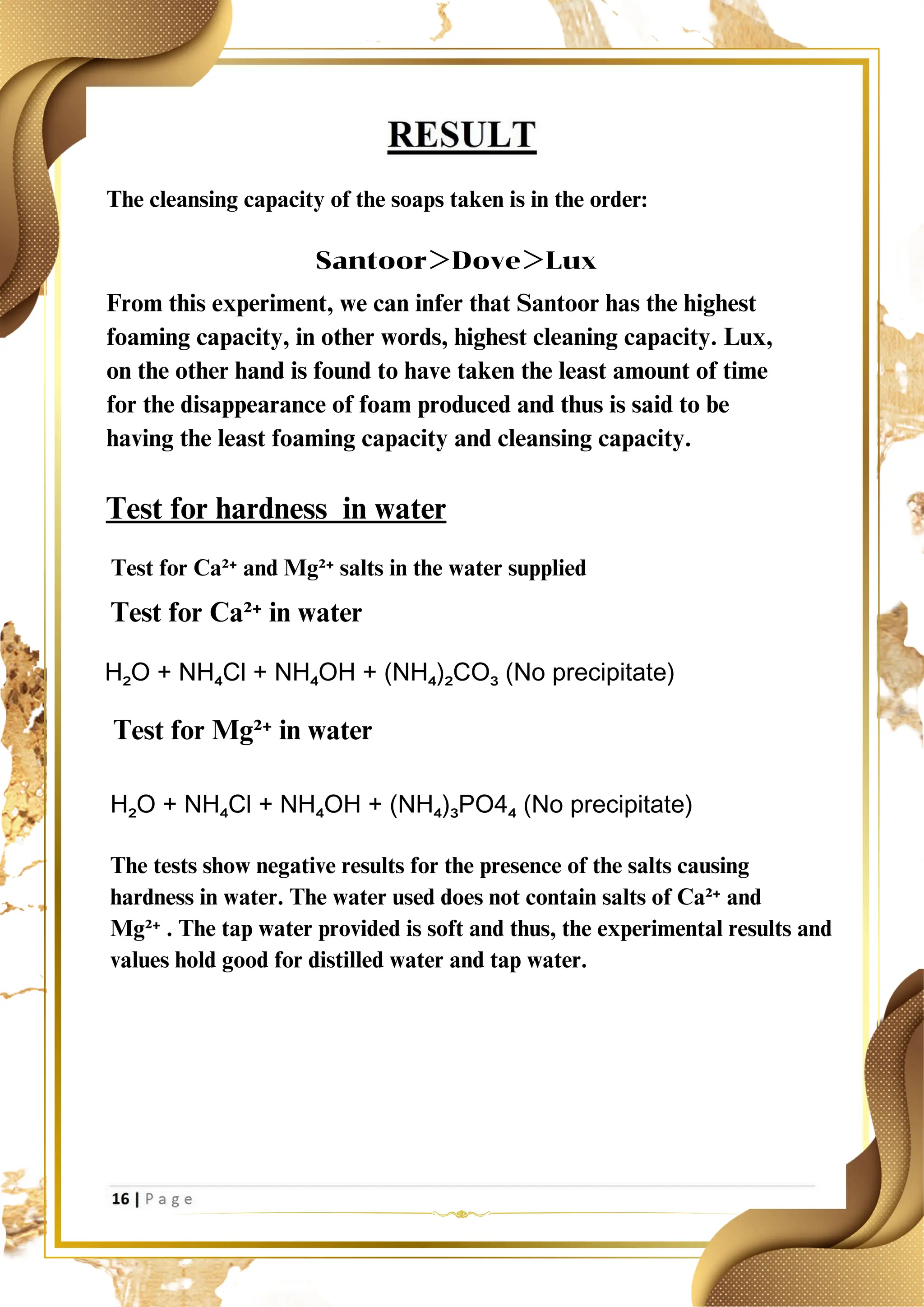

The document certifies Harshit for successfully completing a chemistry project on the foaming capacity of soap under the guidance of Piyali Mam during the academic year 2023-2024. The project explores how soap works, highlights various soap-making methods, and compares the foaming capacities of different soap brands using distilled and tap water. Results indicated that Santoor had the highest foaming capacity, while Lux exhibited the least, showcasing the influence of water hardness on soap effectiveness.