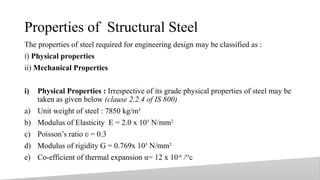

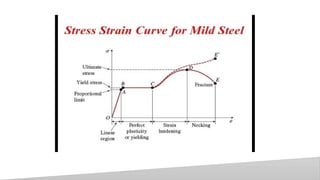

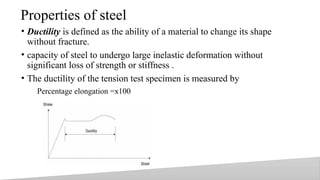

Steel design is a branch of structural engineering focused on the analysis and design of steel members and connections to safely resist applied loads throughout a structure’s service life. It uses the mechanical properties of steel—such as high strength, ductility, and uniformity—to create efficient, economical, and durable structures.

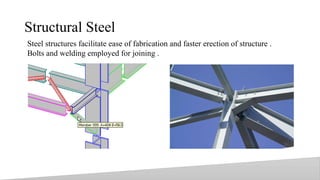

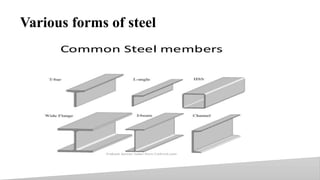

The design process involves determining loads (dead, live, wind, seismic, etc.), analyzing internal forces, and selecting appropriate steel sections that satisfy strength, stability, and serviceability requirements. Common elements include beams, columns, tension members, compression members, and connections (bolted or welded).

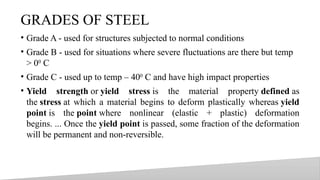

Modern steel design is typically based on limit state principles, such as Load and Resistance Factor Design (LRFD) or Allowable Stress Design (ASD), as specified in design codes (e.g., AISC, Eurocode). Key considerations include yielding, buckling, fatigue, deflection limits, fire resistance, and corrosion protection.

Steel design is widely used in buildings, bridges, industrial structures, towers, and trusses due to its speed of construction, adaptability, and recyclability.