The document discusses various topics related to materials science including:

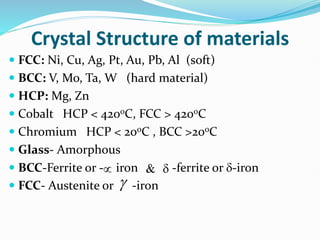

1. Common crystal structures of metals such as FCC, BCC, and HCP and how some metals can change structure with temperature.

2. Plastic deformation in metals occurs through slip and twinning which involve the movement of atoms along crystallographic planes.

3. Atomic structure consists of electrons surrounding the nucleus in shells and the number of valence electrons influence material properties and bonding.

4. Primary bonding types are ionic, covalent, and metallic which influence properties like strength, conductivity, and deformation behavior.