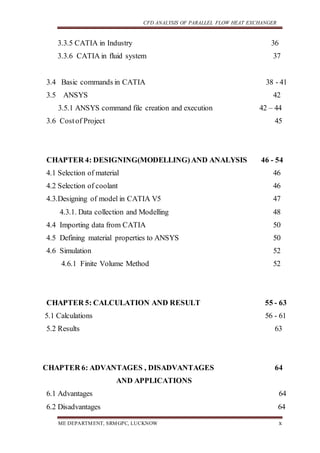

The document details a project titled 'CFD Analysis of Parallel Flow Heat Exchanger' by Anshuman Bajpai, submitted for the Bachelor of Technology degree at Dr. A.P.J. Abdul Kalam Technical University. It includes a comprehensive study of the project's background, methodology, results, and future implications in heat exchanger efficiency. The report acknowledges the support and guidance received during the project and is structured into various chapters focusing on different aspects of the analysis.