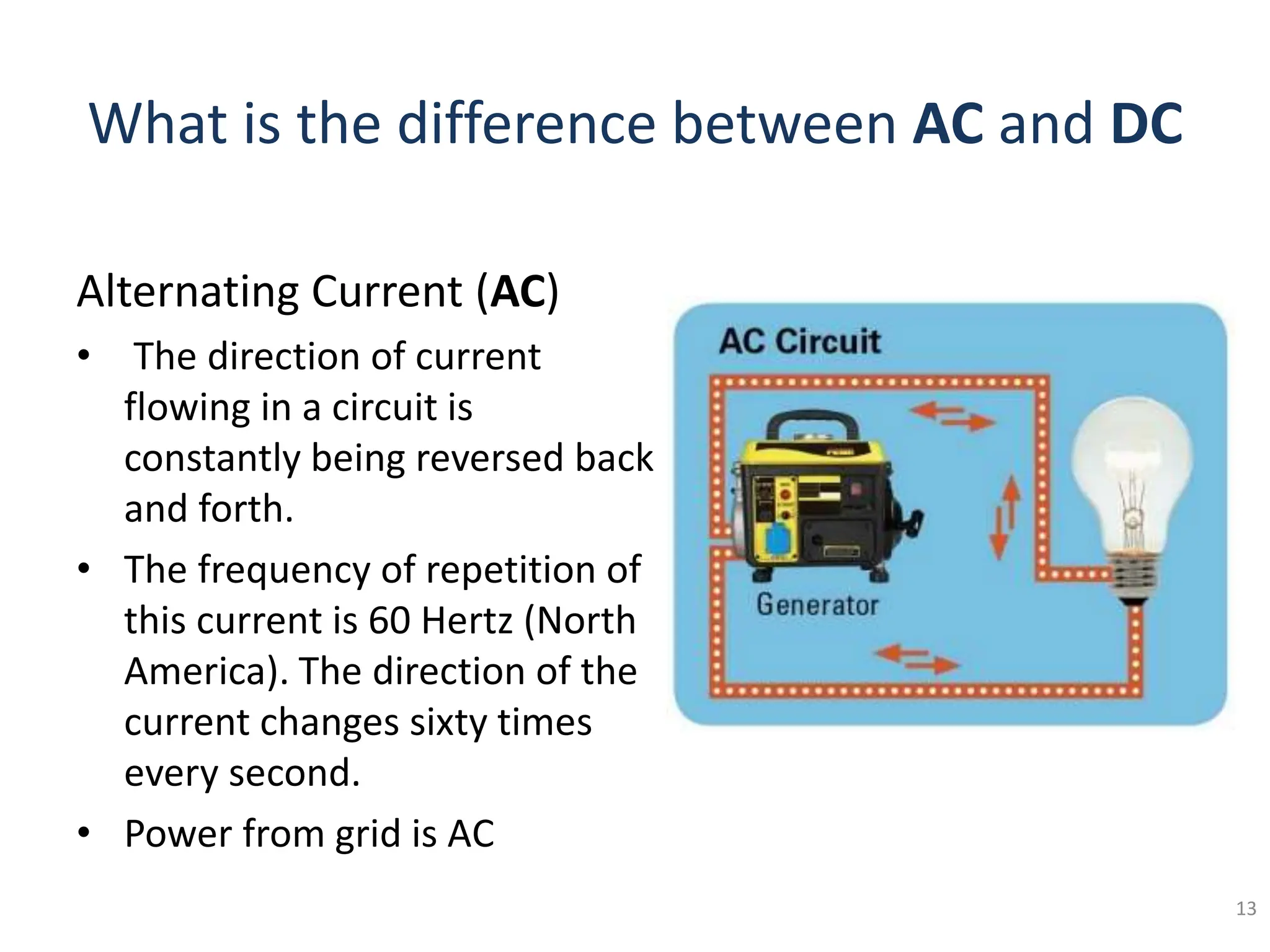

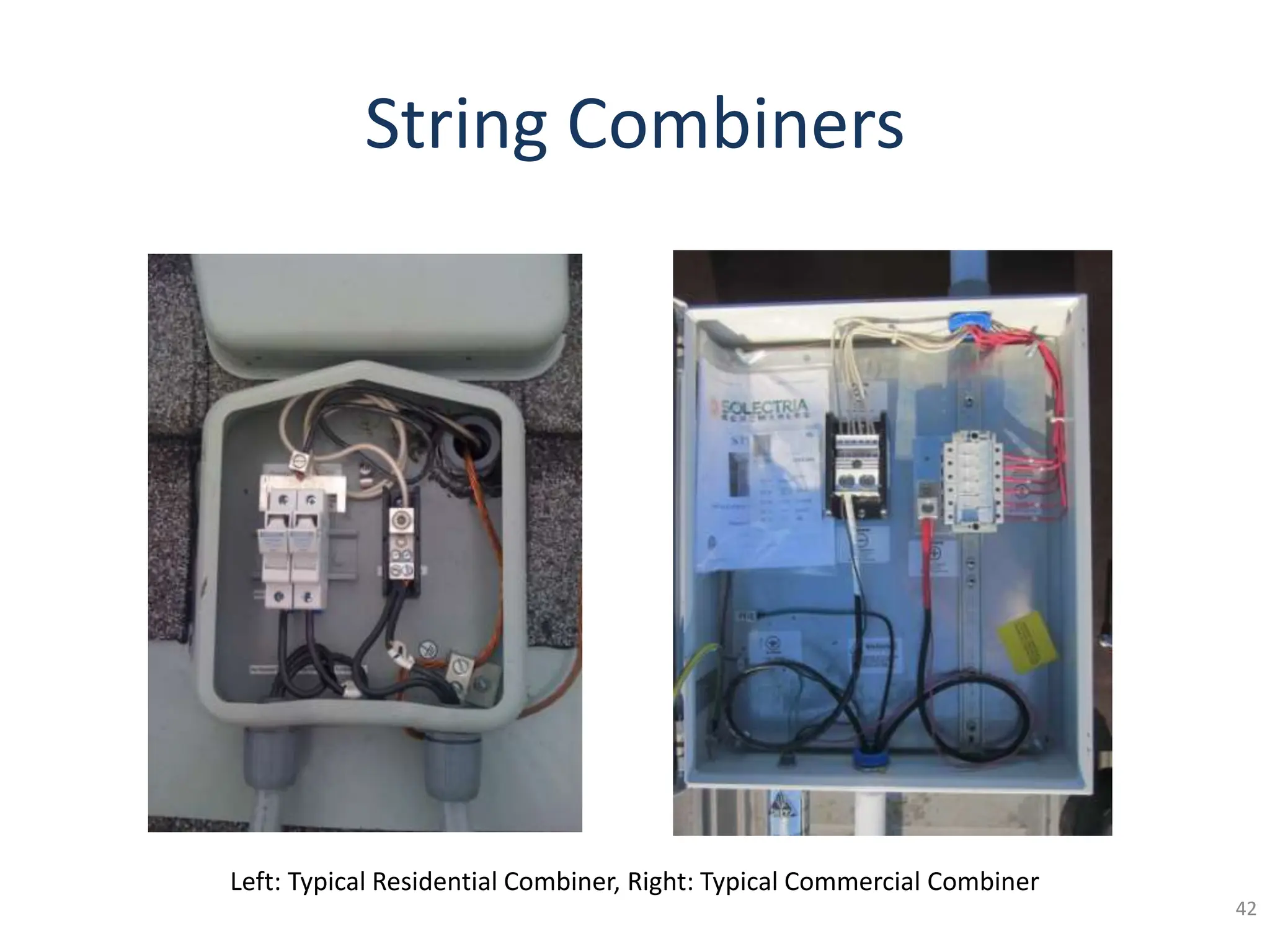

The document outlines the New England Solar Cost-Reduction Partnership and its efforts to reduce soft costs associated with solar photovoltaic (PV) systems through the U.S. Department of Energy's SunShot Initiative. It provides detailed information on solar safety training for firefighters, the operation, components, and hazards of PV systems, as well as standard labeling requirements and tactical considerations for emergency responders. The presentation aims to equip firefighters with essential knowledge to safely handle PV systems during emergencies.