This document provides information on ceramics, including:

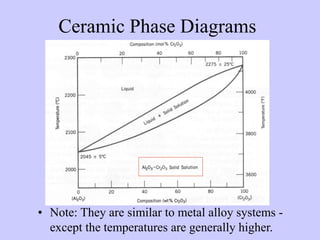

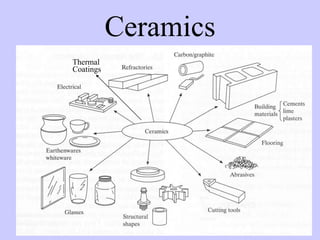

- Ceramics can be amorphous or crystalline, with ionic atomic bonds. Common uses include pottery, bricks, glass, and thermal barrier coatings.

- Crystalline ceramics have good mechanical properties like strength but low ductility. Common structures include NaCl, MgO, and SiC.

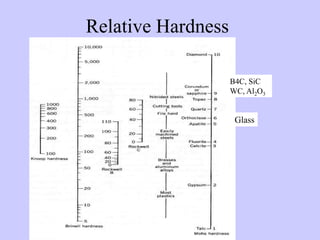

- Important ceramics include silica, carbon forms like diamond and graphite, and fullerenes like C60 which can be superconducting.

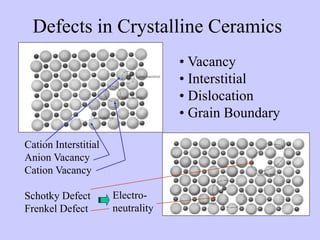

- Defects, mechanical testing methods, and the relationship between properties and porosity are discussed for crystalline ceramics. Glassy ceramics deform viscously

![Try it!

a

a

Cl-

Na+

For this NaCl structure, the

crystal lattice parameter is

a= 2 ( r Na+ + r Cl -),

where r is ionic radius.

Compute the theoretical density of Rock Salt based on its crystal structure.

)

2.16g/cm

(actual

g/cm

14

2

)ions/mol

(6.023x10

)]cm

0.181x10

0

2[(0.102x1

g/mol

35.45)

(22.99

ions

4

N

a

)

A

A

(

4

V

M

3

3

23

3

7

7

A

3

Cl

Na

.

](https://image.slidesharecdn.com/ceramics1-230106173102-7940de00/85/ceramics1-ppt-7-320.jpg)