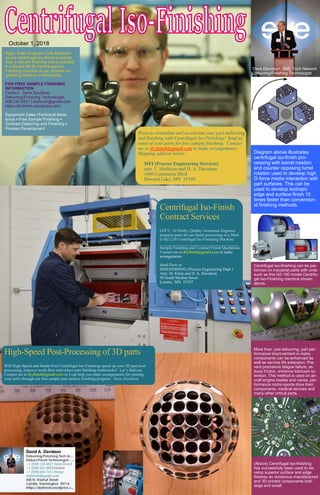

The document describes the centrifugal iso-finishing process, which enhances part surfaces through high g-force media interaction, achieving isotropic finishes significantly faster than conventional methods. This technique is applicable to a variety of industrial components, including aircraft engine parts and medical devices, offering benefits such as improved performance and extended service life. For those interested, options for free sample finishing and contract services are provided, along with contact information for inquiries.