This catalog from Starrett provides an overview of their precision measurement tools and products. It includes sections on micrometers, calipers, height gages, depth gages, indicators and gages, bore gages, tool sets, data collection systems, hardness and surface testers, special gaging, squares, rules, protractors, calipers and dividers, hole and slot gages, fixed gage standards, precision shop tools, machinists' levels, gage blocks, granite surface plates, vision systems, optical comparators, material test and force measurement, laser measurement, precision ground flat stock and drill rod, vocational and educational tools and rules, reference tables, and an index.

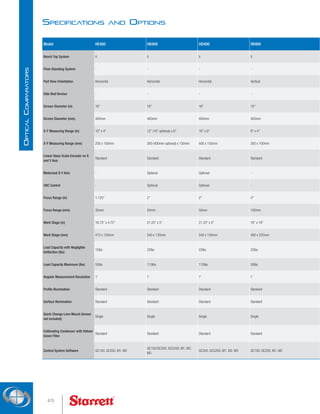

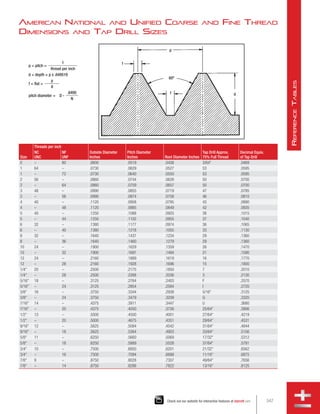

![252 Height Transfer Gages

0-48/0-1200MM

The 252 Height Transfer Gage is ideal for use with test indicators or electronic

amplifiers to accurately transfer height settings from gage blocks, height gages

and other standards.

252 Height Transfer Gages

Range

Fine Adjustment

(Approximate)

Base Size

(Approximate)

Gage Rod

Dimension Cat. No. EDP

0-14

(350mm)

3/8 (9.5mm)

5-3/4 L x 3-1/2 W

(145mm x 90mm)

9 L x .375 Dia.

(225mm x 9.5mm)

with steps

252Z-14 55890

0-24

(600mm)

7-1/2 L x 4-1/2 W

(190mm x 115mm)

252Z-24 51216

0-48

(1200mm)

9 L x 6 W

(225mm x 150mm)

252Z-48 51217

Larger sizes available on special order.

Starrett 708, 709, 711, 650 Test Indicators; 25, 81, 196, 655, 656 Dial Indicators and supplementary

attachments also available.

Gage furnished with 9 (225mm) Rod and PT06784-A Gage Holding Rod in wood case.

Accuracy and Long-Life Features

• Extreme rigidity provides the vibration-proof stability

necessary to permit precise repeat readings with

indicators of the highest amplification

• Extremely rigid, rectangular box-type hollow column

mounted integrally on a heavy base

• Adjusting mechanism is located in the base so the

column and indicator are isolated and not affected by

external factors, such as heat or hand pressure

Ease-of-Operation Features

• Hand-fitting base design for sure-grip handling and

easy movement

• Bottom of the base has three ground and lapped pads

for stability and smooth movement on the surface

plate

• Adjustable slide, incorporating a snug for holding test

indicators or electronic gage heads, has rapid vertical

manual adjustment

• Thumb screw allows slide to be locked

• Knob on base allows fine vertical adjustment of the

slide unit relative to the fixed column.This permits the

slide with its test indicator to be quickly and precisely

adjusted to the desired setting.

Tool and Gaging Holders

• A snug on the slide provides two holes (.375 [9.5mm]

and .156 [4mm]) for holding gage rods or scribers. A

9 (225mm) rod furnished with the gage is especially

useful for reaching confined areas or reaching heights

greater than the range of the gage.

• The rod has a major diameter of .375 (9.5mm) and

stepped diameters of 1/4 (3.2mm) and 7/32 (5.5mm)

at one end and 5/16 (8mm) at the opposite end

• 708 and 709 Test Indicators can be mounted on this

rod using PT22428 swivel clamp. 196 Universal Back-

Plunger Indicators can be mounted using Starrett snugs,

Part PT18718 or PT18724 (snugs not furnished).

• PT06784-A Gage Holding Rod is included to

accommodate the 715-1 Gaging Head when the

Transfer Gage is used with the 717 Electronic Gage.A

wire retaining clip keeps electronic gage head cables

from deflecting the gage-holding rod.

• 25, 81, 655 and 656 Dial Indicators also can be used

on the height gage by means of a PT06784-A Gage

Rod (furnished)

• Other useful attachments (extra) are surface gage

spindles (57C or 57D, 12 [300m]) and 18 [450mm])

– which are extremely useful for scribing and layout

Pictured with 717 Gage Amplifier and

715-12 lever probe.

Height Gage Accessories

121

Check out our website for interactive features at starrett.com

H

eight

G

ages](https://image.slidesharecdn.com/catalog33-precisiontoolcataloglo-res-220727130402-eab0982d/85/Catalog-33-Precision-Tool-Catalog-lo-res-pdf-121-320.jpg)

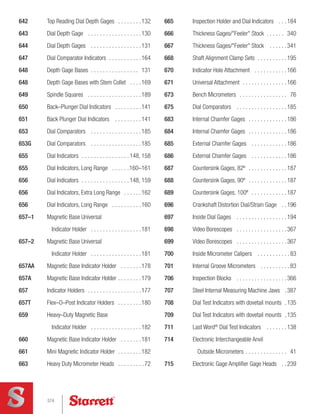

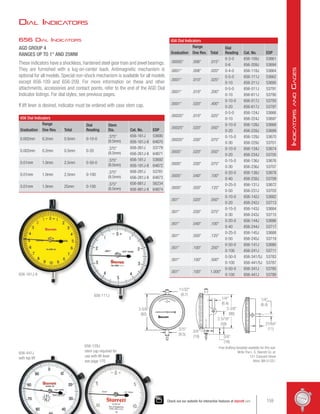

![781XT AccuBore®

Electronic

Bore Gages

See specifications on previous pages

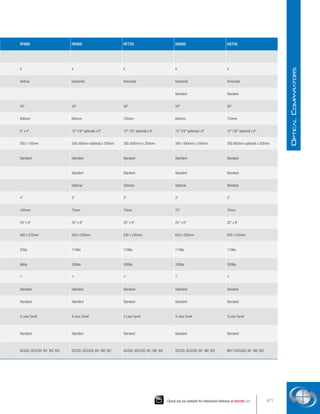

781XT AccuBore Electronic Bore Gage Set – 2-Point Contact (.080-.250 [2-6 mm] Range)

Range

Number of Heads Number of Rings Cat. No. EDP

Inch mm

.080-.250 2-6 5 3 S781XTBZ 68169

781XT AccuBore Electronic Bore Gage Sets –

3-Point Contact (.250-8 [6-200mm] Range – Fixed Anvils)

.250-.375 6-10 2 1 S781XTCZ 68170

.250-.750 6-20 5 3 S781XTHZ 68658

.375-.750 10-20 3 2 S781XTDZ 68171

.750-2.00 20-50 3 3 S781XTEZ 67694

.750-4.00 20-100 6 4 S781XTJZ 67697

2.00-4.00 50-100 3 2 S781XTFZ 67695

4.00-6.00 100-150 2 1 S781XTKZ 67698

4.00-8.00 100-200 4 4 S781XTGZ 67696

6.00-8.00 150-200 2 1 S781XTLZ 67699

Accessories for 781XT AccuBore Electronic Bore Gages

Description Part No. EDP

Cable Link to 772 Data Collector, 761 Multiplexer PT61340 65648

Starrett Module #4 for 772 Data Collector, 761 Multiplexer PT61285 65647

Two 3-volt Batteries, No. CR2032 PT99492 65650

Larger sizes available on special order.

Gages are also available with dial indicators on special order.

Extensions for 781XT AccuBore Electronic Bore Gages

Cat. No. EDP

Ext. Size

Fits Models

Model Size

Inches mm Inches mm

78/782F 65484 2.5 63 78XT/780XT/781XT/782XT - 250-375mm 1/4-5/16 6-8

78/782G 65485 3 75 78XT/780XT/781XT/782XT - 375-500mm 3/8-1/2 10-12.5

78/782H 65486 4 100 78XT/780XT/781XT/782XT - 625-750mm 1/2-3/4 12.5-20

78/782J 65487 6 150 78XT/780XT/781XT/782XT - 1 thru 2 3/4-2 20-50

78/782K 65488 6 150 78XT/780XT/781XT/782XT - 2 thru 12 2-12 50-300

Extensions from 2-1/2 - 6 can be added to the 781XT,

enabling internal measurements in deep hole bores

S780XTKZ

Electronic Bore Gages

208

B

ore

G

ages](https://image.slidesharecdn.com/catalog33-precisiontoolcataloglo-res-220727130402-eab0982d/85/Catalog-33-Precision-Tool-Catalog-lo-res-pdf-208-320.jpg)

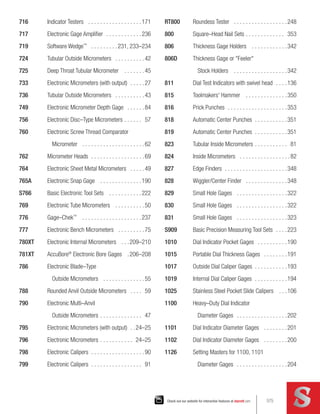

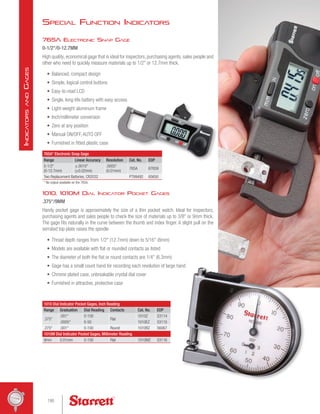

![Electronic Bore Gages

780XT Electronic Internal Micrometers with IP65

Protection (with output)

See specifications on previous page

780XT Electronic Internal Micrometer Sets, 2-Point Contact (.080-.250 [2-6mm] Range)

Range

No. of Heads No. of Rings Cat. No. EDP

Inch mm

.080-.250 2-6 S780XTBZ 12043

780XT Electronic Internal Micrometer Sets, 3-Point Contact (1/4-8 [6-200mm] Range), Fixed anvils

1/4-3/8 6-10 2 1 S780XTCZ 12044

3/8-3/4 10-20 3 2 S780XTDZ 12045

3/4-2 20-50 3 2 S780XTEZ 12046

2-4 50-100 3 2 S780XTFZ 12047

4-6 100-150 2 1 S780XTKZ 12049

4-8 100-200 4 2 S780XTGZ 12048

6-8 150-200 2 1 S780XTLZ 12050

Internal Extensions

Ext. Size

Fits Models

Model Size

Cat. No. EDP

Inch mm Inch mm

2.5 63 78XT/780XT/781XT–312-375 1/4-3/8 6-10 78/782F 65484

3 75 78XT/780XT/781XT–375-500 3/8-1/2 10-12.5 78/782G 65485

4 100 78XT/780XT/781XT–625-750 1/2-3/4 12.5-20 78/782H 65486

6 150 78XT/780XT/781XT–1 thru 2 3/4-2 20-50 78/782J 65487

6 150 78XT/780XT/781XT–2 thru 12 2-12 50-300 78/782K 65488

Internal Extensions for 78, 780, 781

Internal Micrometers

Extensions from 2-1/2 - 6 can be added to both the 780XT and 78XT, enabling internal

measurements in deep hole bores (Multiple extensions can also be used).

210

B

ore

G

ages](https://image.slidesharecdn.com/catalog33-precisiontoolcataloglo-res-220727130402-eab0982d/85/Catalog-33-Precision-Tool-Catalog-lo-res-pdf-210-320.jpg)

![Precision Rules

End Graduations

End graduations are useful for measuring depths, widths

of shoulders, recesses, grooves, etc. They are graduated in

32nds of an inch or millimeters on both ends of one side as

shown at the right.

Adjustable Steel Hook Rules

These improved Hook Rules feature an adjustable double

hook that can be shortened or extended on either side

in relation to any one of the four graduations on the rule.

This allows accurate measurements from shallow or deep

shoulders and also permits setting inside calipers to any of

the graduations. Hooks are hardened and may be adjusted

or removed by a slight turn of an eccentric stud.

Steel Hook Rules with Reversible Hook

These convenient Hook Rules permit accurate

measurements, even when the user cannot see if the rule

is aligned with the measuring edge.This is especially useful

for measuring from round corners, through hubs, for setting

inside calipers, etc. The single hook is hardened and may

be reversed or removed by a slight turn of an eccentric

stud.

Narrow Hook Rules with Reversible Hook

These useful Hook Rules are similar to the Hook Rules

described above, but have a narrow blade (only 3/16

[4.8mm] wide) which permits measurements through

holes as small as 7/32 (5.5mm) in diameter. Hooks are

hardened and may be reversed or removed by a partial turn

of the eccentric stud.

Steel Rule with Tapered End

This 6 rule, our C310T-6, is a favorite with all mechanics

because the tapered end permits measuring insides of

small holes, narrow slots, grooves, recesses, etc. The rule

has a taper from 1/2 width at the 2 graduation to 1/8

width at the end. Accurate, distinctive, photo-engraved

graduations in 32nds are on one side and 64ths on the

reverse side, with graduations always in a normal, easy-

to-read position. Made of tempered, full-flexible steel with

satin chrome finish.

Steel Rule with Pocket Clip

This handy 6 rule is designed for frequent use. It is made

of tempered, full-flexible steel and has accurate, photo-

engraved graduations in 32nds on one edge and 64ths on

the opposite edge, with satin chrome finish. C310K-6.

Useful Variation Features of Our Standard Precision Rules

289

Check out our website for interactive features at starrett.com

P

recision

R

ules

,

S

traight

E

dges

,

P

arallels](https://image.slidesharecdn.com/catalog33-precisiontoolcataloglo-res-220727130402-eab0982d/85/Catalog-33-Precision-Tool-Catalog-lo-res-pdf-289-320.jpg)

![Steel Beam Trammels

C251 Steel Beam Trammels

and Attachments

10-1/2 – 20/260 - 500MM BEAMS

A rigid, well-designed trammel for layout, scribing, and

measuring distances and circles. The top of the beam

is flattened so that when the trams are clamped in

position, they will not turn from pressure on the points.

The trams are held in place by spring friction, which

prevents them from sliding when the nuts are loosened

for setting. One tram has a fine-adjusting screw for the

points.

Each tram has a knurled swivel grip at the top that

turns freely, making it very convenient to swing the tool

when scribing circles. The 3 (75mm) points may be

adjusted for length in the spring chucks and can be

easily replaced with caliper legs or other attachments

listed. The ball points with 3 (75mm) holder permit

working from holes up to 1-1/2 (38mm) in diameter.A

pair of 3 (75mm) caliper points is included with each

trammel.

• Ideal for draftsmen, engineers, metal-workers for

layout work, scribing and measuring

• Furnished with rigid steel beam – 10-1/2

(263mm), 14-1/2 (360mm) or 20 (500mm)

sizes

• Bright chrome finish for longer life, resistance to

corrosion

• Highly versatile – handy attachments available to

extend range and measure

C251A

J

H

D

E

C251 Steel Beam Trammels

Max. Dividing Range Max. Circle Scribing Diameter Range Beam Size

Cat. No. EDP

Inch mm Inch mm Inch mm

9 225mm 18 450mm 10-1/2 263mm C251A 51205

13-1/2 338mm 26 650mm 14-1/2 363mm C251B 51207

18 450mm 36 900mm 20 500mm C251C 51209

C251 Trammel Individual Attachments Only

Description Photo Key Cat. No. EDP

Coupling, with Extra 20 (600mm) Beam (When used with C251C will scribe circle 72 [1800mm] diameter) D C251D 51211

Ball Points and Holder E C251E 51212

Steel Point and Socket (One) (Has .076 [1.9mm] hole diameter to hold leads) H C251H 51214

Needle Point (Chrome not available) (One) J 251J 51203

320

C

alipers

,

D

ividers

and

T

rammels](https://image.slidesharecdn.com/catalog33-precisiontoolcataloglo-res-220727130402-eab0982d/85/Catalog-33-Precision-Tool-Catalog-lo-res-pdf-320-320.jpg)

![568 V-Blocks and Clamps for Round or Square Work

2/50MM ROUND CAPACITY

1-7/16/36MM SQUARE CAPACITY

These rugged and versatile blocks have the following features:

• Hardened steel, precision ground parallel and square

• V-grooves are ground central and parallel to the sides and base – perfect alignment in

matched pairs

• Clamps have screw holes at 45º and 90º to hold either square or round work

• Stepped groove construction permits

high or low clamp mounting for small or

large work

• Clamps do not project over the width of

the block, permitting it to be used on the

base, ends or sides

• 3/8-16 tapped holes permit mounting

blocks on faceplates or angle irons

• Each block is 2-1/2 long x 3 wide x 2

high (63 x 75 x 50mm)

Precision V-Blocks

566 Dual-Vee Magnetic V-Block

1-3/4/44MM CAPACITY

• Designed for versatility and accuracy

• All working surfaces are precision ground

• Two precision vees will hold round stock sizes from

1/4 - 1-3/4 (6.4-44mm) diameter

• Powerful, permanent magnet is controlled by a rotary

switch

• All working surfaces are heat treated for long wear

and stability

• Each block is 2-1/2 wide x 3 high x 3 long (63 x

75 x 75mm)

566 Dual-Vee Magnetic V-Block

Capacity

Description Cat. No. EDP

Inch mm

1-3/4 44 Dual-Vee Magnetic V-Block 566 63323

568 V-Blocks and Clamps

2 (50mm) Dia. Round;

1-7/16 (36mm) Square

(1-9/16 [40mm] with Screw at Top)

1 V-Block and Clamp 568A 52590

Complete Set with 2 V-Blocks and 2 Clamps (Matched

Pair)

568C 52592

Clamp Only 568B 52591

2.97

(85.4)

2.53

(64.3)

Pair of 568 V-Blocks

1.5

(38.1)

1.98

(50.3)

566

361

Check out our website for interactive features at starrett.com

P

recision

S

hop

T

ools](https://image.slidesharecdn.com/catalog33-precisiontoolcataloglo-res-220727130402-eab0982d/85/Catalog-33-Precision-Tool-Catalog-lo-res-pdf-361-320.jpg)

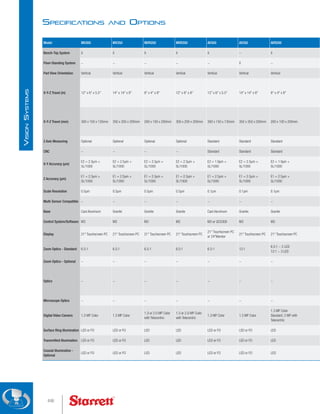

![Features

• X-Y travel for AVR200: 8 x 4 (200 x 100 mm)

• X-Y travel for AVR300: 12 x 8 (300 x 200 mm)

• Z travel: 8 (200 mm) with 2.0x auxiliary lens

• Full CNC X-Y-Z positioning or motorized manual

positioning using a pendant with joystick and

trackball

• Windows®

7 Professional operating system for

network connectivity

• MetLogix M3 CNC metrology software

• Video edge detection (VED)

• Field-of-view (FOV) measurements integrated

with stage motion

• Renishaw scales for .00002 (0.1µm) of X,Y and

Z axis

• Accuracy: 2.5µm + 5L/1000 for X and Y, 3.5µm

+ 5L/1000 for Z

• Color digital video camera

• Collimated LED sub-stage illumination

• Ring Light LED surface illumination

• Granite base

• AVR200 H x W x D: 34 x 20.5 x 27 (863 x 520

x 685mm)

• AVR300 H x W x D: 34 x 29.2x 35 (865 x 740

x 890mm)

Options

• Dedicated 6.5:1 or 12:1 CNC zoom optics

• Quick-change bayonet lens mount for telecentric

optics

• Bayonet mountable 0.30x, 0.50x, 0.80x, 1.0x,

2.0x, 4.0x telecentric optics

• 0.5x, 1.5x and 2.0x auxiliary lenses for zoom

optics

• Quadrant LED surface illumination for zoom optics

• DXF/FOV option pack for automatic comparison to

CAD designs

• Modular system workstation

• Calibration standards

Weight and Dimensions

AVR200 AVR300

Net Weight

200lbs 250lbs

90kg 113kg

Shipping Weight

250lbs 300lbs

115kg 135kg

Automatic Vision Metrology Systems

AVR

AVR200 AND AVR300

The AVR CNC automatic vision metrology systems are ideal for repetitive

measurements and automatic comparison to CAD files. They are available with

dedicated zoom optics or a quick-change bayonet lens mount which accepts a

choice of telecentric lenses for micron-level resolution and optical distortion down to

0.001% for accurate field-of-view (FOV) measurements. These can encompass an

entire small part up to 2.00 x 1.50 or a feature of a larger part and be seamlessly

integrated with stage motion to measure parts with a length up to 8 (AVR200) or

12 (AVR300).

AVR hardware features a granite base for maximum stability, recirculating ball

linear guides for smooth and precise stage motion, and full CNC control for high

throughput. The AVR line is built around a 21 all-in-one touch screen PC which

runs MetLogix M3-CNC software under Windows®

7. M3 software capabilities

include 3-axis measurements and 2D geometrical constructs (points, lines, angles,

rectangles).

AVR200

[ 487 ]

Ø19.2

[ 520 ]

20.5

[ 872 ]

34.3

[ 682 ]

26.9

[ 235 ]

9.3

[ 193 ]

7.6

[ 495 ]

Ø19.5

AV300

[ 673 ]

26.49

[ 617 ]

Ø24.30

[ 228 ]

8.98

[ 200 ]

7.88

[ 846 ]

33.31

[ 698 ]

Ø27.49

[ 872 ]

34.34

For more information please see the Options and

Specifications table at the end of this section.

432

V

ision

S

ystems

NEW!](https://image.slidesharecdn.com/catalog33-precisiontoolcataloglo-res-220727130402-eab0982d/85/Catalog-33-Precision-Tool-Catalog-lo-res-pdf-432-320.jpg)

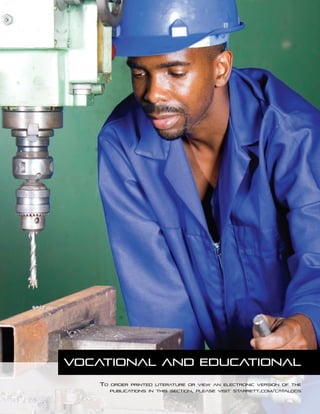

![Side Bed Optical Comparators

HS600

The HS600 floor-standing horizontal optical comparator has all the

same features as the HF600, except it has the screen position set

to the side of the workstage area allowing close, comfortable and

unrestricted access to the viewing and control area. It has a 12

(300mm) X-axis (16 [400mm] optional) and 8 (200mm) Y-Axis

motorized travel (CNC control optional), Q-axis digital protractor with

angular measurements to 1' resolution, and your choice of powerful

Quadra-Chek®

or MetLogix™

software control systems.A time tested,

cost-effective solution for non-contact measurement.They are simple

to use, yet have excellent capacity and performance to satisfy an

exceptionally wide range of dimensional inspection applications and

complex measuring requirements. At the heart of these systems are

precision optics, superb lighting, and a highly accurate workstage that

combine to ensure bright, sharp images and exceptional accuracy.

Features and Specifications

• Accommodates components up to 330lbs (150kg)

• 24 (600mm) diameter screen

• 4 lens capacity

• Canopy and curtains standard

• Automatic edge detection option

• 20 (500mm) extended workstage available

HS750

The HS750 floor-standing horizontal optical comparator has all the

same features as the HF750, except it has the screen position set

to the side of the workstage area allowing close, comfortable and

unrestricted access to the viewing and control area. It has an extra

large 30 (762mm) screen, 12 (300mm) X-axis (16 [400mm]

optional) and 8 (200mm) Y-Axis motorized travel (CNC control

optional), lens turret with 3 lens capacity, Q-axis digital protractor

with angular measurements to 1' resolution, powerful Quadra-Chek®

or MetLogix™

software control systems, canopy and curtains. A time

tested, cost-effective solution for non-contact measurement.They are

simple to use, yet have excellent capacity and performance to satisfy

an exceptionally wide range of dimensional inspection applications

and complex measuring requirements. At the heart of these systems

are precision optics, superb lighting and a highly accurate workstage

that combine to ensure bright,sharp images and exceptional accuracy.

Features and Specifications

• Very rigid and inherently stable metal construction ensures

optimum performance and accuracy

• Large diameter screens provide extensive field of view giving the

user more component detail on the screen

• Side screen design gives the operator uninterrupted access to

the screen and working area

• Large workstage, power driven on both axes, with high load

capacity

• CNC workstage option

• 20 (500mm) extended travel workstage available

• Available with the full range of Quadra-Chek®

or

MetLogix™

readout systems

• Canopy and curtains standard

• Wide range of ancilliaries and options allows specification

tailoring and easy upgrading

• Accessories include alternative workstage, precision centers,

vees, vices etc.

For more information please see the Options and

Specifications table at the end of this section.

466

O

ptical

C

omparators](https://image.slidesharecdn.com/catalog33-precisiontoolcataloglo-res-220727130402-eab0982d/85/Catalog-33-Precision-Tool-Catalog-lo-res-pdf-466-320.jpg)