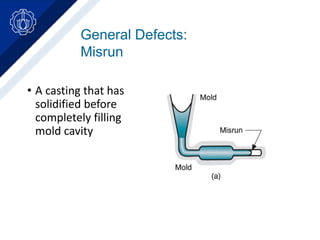

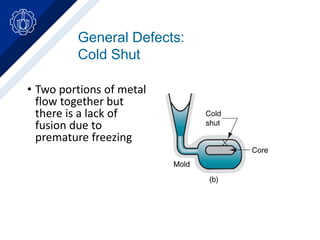

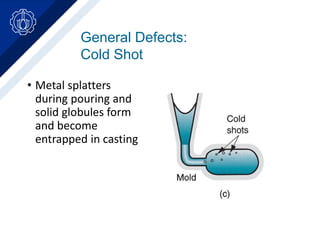

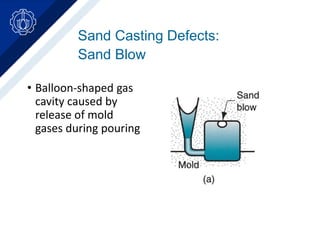

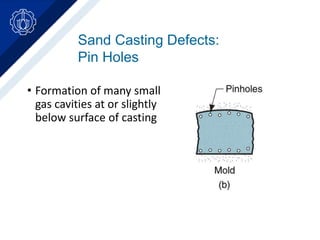

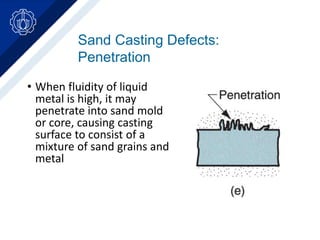

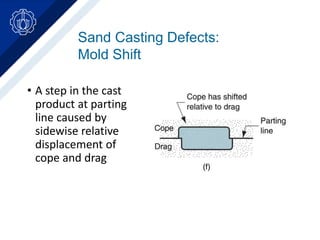

The document discusses casting quality and defects that can occur during the casting process. It describes general defects that can happen with any casting method as well as defects specific to sand casting. It also covers casting materials, including ferrous alloys like cast iron and steel, and nonferrous alloys such as aluminum, copper, and zinc alloys. Product design considerations for castings are outlined such as simplifying geometry, avoiding sharp corners, and allowing for tolerances and machining.