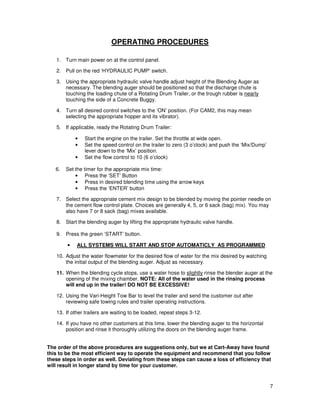

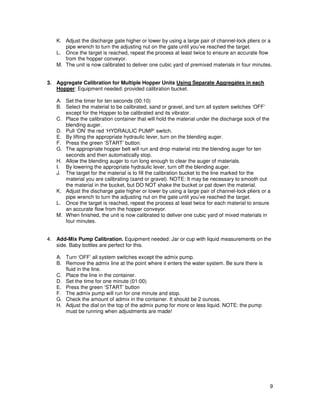

This document serves as the owner's manual for Cart-Away cam loading units, detailing essential operational guidelines, calibration processes, and safety precautions. It covers safe operation rules, material selection, specific water requirements per yard of concrete, timer and operating procedures, and steps for calibration of various components. Additionally, it emphasizes the importance of maintaining safety and efficiency while operating the machinery.