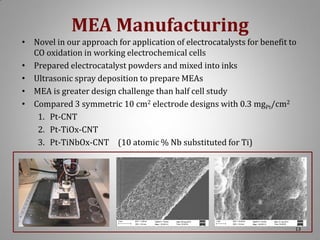

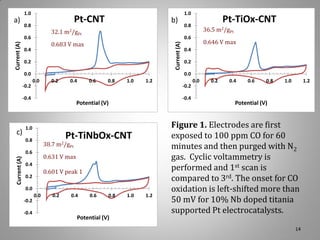

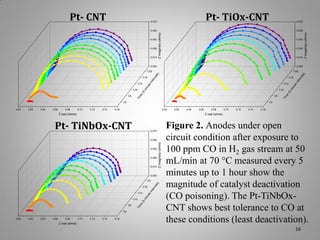

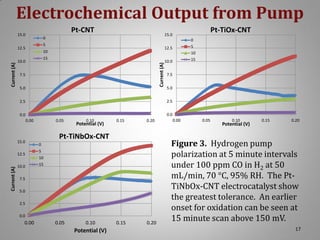

This document provides information on a project to develop resilient oxidation catalysts for electrochemical hydrogen pumps. The project goals were to improve the activity and durability of electrocatalysts used in hydrogen pumps by designing composite support structures. Specifically, the project involved synthesizing platinum electrocatalysts supported on carbon nanotube-titania and carbon nanotube-titanium niobium oxide composites, and testing their performance in membrane electrode assemblies. Testing showed the composite supported catalysts had better tolerance to carbon monoxide poisoning and higher carbon corrosion resistance compared to platinum on carbon nanotubes alone.

![Project Goals

• Problem: Hydrogen oxidation electrocatalysts are used

in anode of hydrogen pump and fuel cell. They are subject

to poisoning from impurities like carbon monoxide [CO]

and durability concerns that arise from cleaning up CO.

• Challenge: Develop supports which can improve the

activity and durability of electrocatalysts for H2 pump.

• Approach: Design a composite support structure which

can aid in the improvement of both desired properties.

Demonstrate performance improvements through

working membrane electrode assemblies (MEA). Study

the material behavior and elucidate the benefits.

3](https://image.slidesharecdn.com/teamcapitalisprogressfinal-131017155458-phpapp02/85/CapItalIs-Fuel-Cell-Challenge-V-Presentation-3-320.jpg)

![Metal Oxides & Defect Chemistry

By metal oxide doping of Ti site with Nb,

𝑁𝑏2 𝑂5

2 𝑇𝑖𝑂2

1

2 𝑁𝑏·𝑇𝑖 + 4 𝑂 𝑂𝑋 + 2 𝑂2 + 2 𝑒 −

The equilibrium reaction for oxygen at low pressures is:

1

𝑂 𝑂𝑋 ⇌ 𝑉 ·· + 2 𝑒 − + 2 𝑂2

𝑂

The mass action law follows this expression for the equilibrium constant K

for electrons

𝑉 ·· ∗[𝑛]2

𝑂

[𝑂2 ]1/2

= 𝐾 𝑛 where [O2] = Partial pressure of O2 or P(O2)

At low P(O2), where e- compensates for the oxygen vacancies [n] ≈ 2 𝑉 ··

𝑂

1

2

𝑛 ∗ 𝑛

2

1

−2

= 𝐾 𝑛 ∗ 𝑃(𝑂2 )

1

3

𝑛 = (2𝐾 𝑛 ) ∗ 𝑃(𝑂2 )

therefore,

1

−6

11](https://image.slidesharecdn.com/teamcapitalisprogressfinal-131017155458-phpapp02/85/CapItalIs-Fuel-Cell-Challenge-V-Presentation-11-320.jpg)

![XRD Spectra of Composite Support

and effect of [C:Ti] atomic ratio

Effect of Titanium Isopropoxide

added to fixed 0.1 g mass of CNT

Titanium Moles Added

Power (Ti moles)

6.E-04

[10:1]

60000

Ti moles

7.E-04

5.E-04

4.E-04

3.E-04

50000

40000

30000

20000

[80:1]

2.E-04

[80:1]

70000

[10:1]

8.E-04

80000

Intensity (counts)

9.E-04

XRD Spectra of TiOx-CNT Catalyst Supports

10000

1.E-04

0.E+00

0

100

200

[Ti:C] Atomic Ratio

300

400

0

10

30

50

70

90

2Ѳ

XRD scans show the presence of small anatase crystallites on the carbon nanotube

support. A higher titanium loading of 10:1 had a greater resistance and also

lacked sufficient electronic contact to function as electrocatalyst as evidenced by

the minimal ECSA and lack of i-V performance. A lowered ration of C:Ti [80:1] (5%

18

mass ratio of Ti) was used successfully.](https://image.slidesharecdn.com/teamcapitalisprogressfinal-131017155458-phpapp02/85/CapItalIs-Fuel-Cell-Challenge-V-Presentation-18-320.jpg)

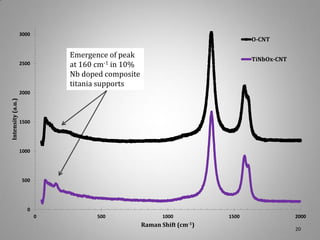

![Raman Spectra of Composite Support

Raman Spectra of CNT:Titania

18000

Titania-CNT

Oxidized-CNT

16000

25000

12000

20000

10000

8000

6000

4000

2000

0

0

500

1000

1500

2000

Intensity (a.u.)

Intensity (a. u.)

14000

[80:1]

15000

[10:1]

10000

TiNbOx

5000

-1

Raman Shift (cm )

0

0

500

1000

1500

2000

Raman Shift (cm-1)

Raman data from red laser also shows the confirmation

of dual phase support with presence of anatase. The

concentration of titania on the surface may have an effect

on the material’s band gap, Eg. Later, dopant Nb atoms

wer added to effectively reduce the titanium oxidation

state and increase its electronic conductivity.

W. F. Zhang, Y. L. He, M. S. Zhang, Z Yin, Q. Chen. Raman scattering study on anatase TiO2 nanocrystals. J. Phys. D: Appl. Phys. 33, 912–916 (2000).

19](https://image.slidesharecdn.com/teamcapitalisprogressfinal-131017155458-phpapp02/85/CapItalIs-Fuel-Cell-Challenge-V-Presentation-19-320.jpg)

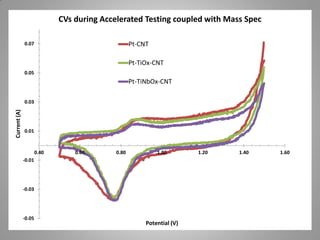

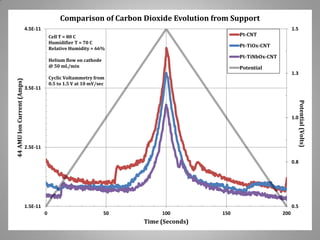

![Carbon Corrosion Resistance

L. M. Roen, C. H. Paik, and T. D. Jarvi. Electrocatalytic Corrosion of Carbon Support in PEMFC Cathodes.

Electrochemical and Solid-State Letters. 7 (1), A-19-A22, 2004.

A method to quickly screen electrocatalyst durability achieved by scanning cell

potential and monitoring the evolution of carbon dioxide [CO2+] ion current by mass

spectrometer from sample capillary attached to the exhaust line. Real time

concentrations can be correlated with potential dynamic.

21](https://image.slidesharecdn.com/teamcapitalisprogressfinal-131017155458-phpapp02/85/CapItalIs-Fuel-Cell-Challenge-V-Presentation-21-320.jpg)

![Electron Microscopy

Distribution of Pt Crystallites

0.40

Frequency

0.35

0.30

0.25

0.20

Atomic ratio near 1:1 between Ti:Pt

in this image from STEM and EDX

0.15

0.10

0.05

0.00

2-2.5 2.5-3 3-3.5 3.5-4 4-4.5 4.5-5 5-5.5

[Ti]

Pt Crtystallite Diameter (nm)

HRTEM of Pt particle distribution on support (above)

TEM at USC shows area for improvement and also a

single CNT/Pt electrocatalys (below; left and right)

[O]

Credit: Haijun Qian and JoAn Hudson at Clemson EMF for HRTEM and STEM images & EDX data

[Pt]

23](https://image.slidesharecdn.com/teamcapitalisprogressfinal-131017155458-phpapp02/85/CapItalIs-Fuel-Cell-Challenge-V-Presentation-23-320.jpg)

![Raman Spectra of Carbon:Titanium Catalyst Supports

Raman Spectroscopy

25000

20000

[80:1]

Intensity (a.u.)

15000

[10:1]

TiNbOx

10000

5000

0

0

200

400

600

800

1000

Raman Shift

1200

1400

1600

1800

2000

(cm-1)

32](https://image.slidesharecdn.com/teamcapitalisprogressfinal-131017155458-phpapp02/85/CapItalIs-Fuel-Cell-Challenge-V-Presentation-32-320.jpg)