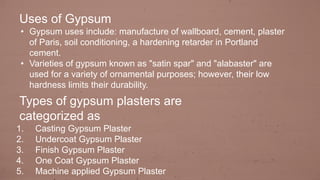

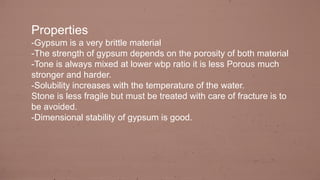

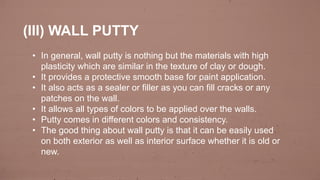

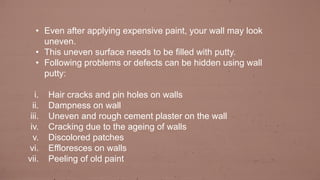

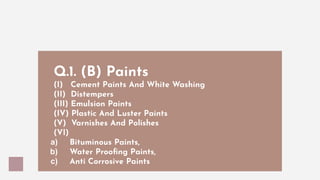

The document provides detailed notes on building materials, specifically applied finishes such as plaster of Paris, gypsum plaster, and wall putty, along with their properties, applications, and methods of use. It describes various types of paints, including cement paints, distempers, emulsion paints, and varnishes, outlining their compositions, advantages, and applications in construction. Additionally, the notes cover the application procedures and benefits of these materials in achieving a smooth, durable finish for both interior and exterior walls.