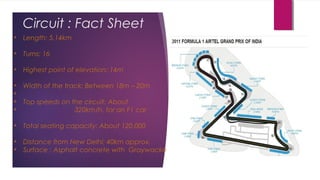

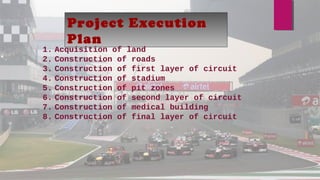

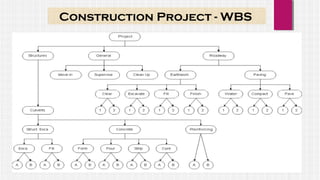

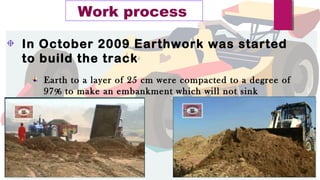

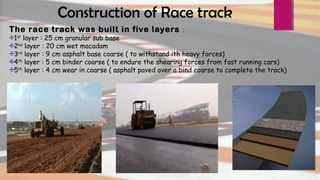

The document provides details about the Jaypee International Circuit located in Greater Noida, India. It summarizes that the circuit was constructed between 2007-2011 at a cost of 20 billion INR. Some key facts are that the 5.14km circuit has 16 turns and can accommodate 120,000 spectators. Construction involved removing 4 million cubic tons of earth and using 325,000 tons of asphalt among other materials. The circuit hosts Formula One races and aims to promote India as a multi-sport nation and boost tourism.