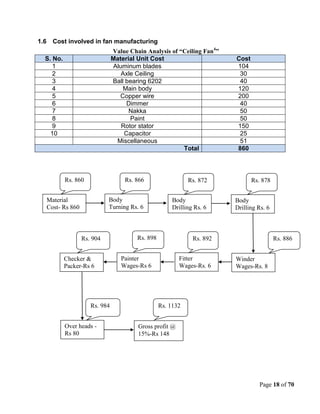

1. This document reports on the manufacturing processes, materials, and costs for ceiling fan production in Pakistan.

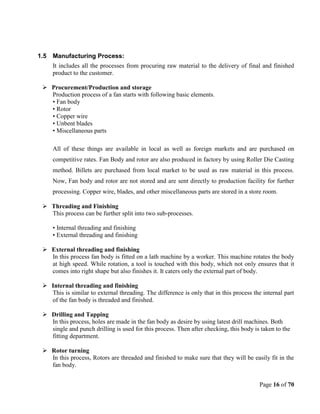

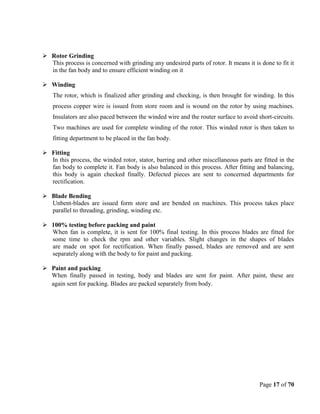

2. It describes the production methods used by small, medium, and large fan manufacturers, including the types of machinery and manufacturing steps used.

3. Key raw materials include electric steel sheets, aluminum, enameled copper wire, ball bearings, and steel rod. Constraints on supplies of quality raw materials like ball bearings and electric steel sheets negatively impact fan quality and export competitiveness.