This document provides instructions for making a takedown recurve bow. It lists the necessary tools and materials, which include a youth bow kit, wood, metal plates and screws. It then provides 18 steps to assemble the bow, including cutting the limbs to length, drilling holes to attach the limbs to the wooden riser grip, and adding metal plates and screws to connect the limbs securely while allowing them to be detached. The final steps include stringing the bow and making a carrying case.

![United States Patent [191

Karbo

[11 1 3,738,348

[45] June 12, 1973

[54] TAKE-DOWN ARCHERY BOW

[75] Inventor: Richard S. Karbo, Whittier, Calif.

[73] Assignee: Brunswick Corporation, Chicago, Ill.

[22] Filed: Feb. 11, 9171

[21] Appl. No.: 114,567

[52] U.S. Cl. ............................ .. 124/24, 273/DIG. 7

[51] Int. Cl. ............................................ .. F41b 5/00

[58] Field of Search ................ .. 124/24, 23, 22, 25,

124/41, 35

[56] References Cited

UNITED STATES PATENTS

3,527,196 9/l970 Karbo l . . . . . . . l . . . . . . . . . . . . . . .. 124/20

2,163,503 6/1939 Tate . . . . . . . . . . . . . . . . . . . . . .. 124/23

2,642,661 6/1953 Fredrickson . . . . . . . . . .. 124/23

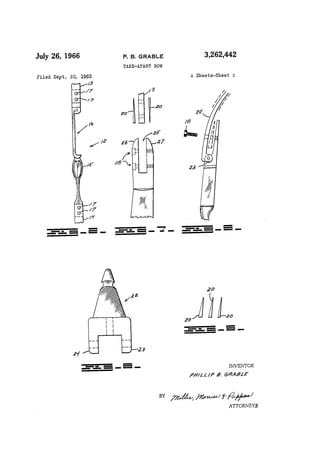

3,262,442 7/1966 Grable ................................ .. 124/24

Primary Examiner-Richard C. Pinkham

Assistant Examiner-William R. Browne

Att0rney—D0nald S. Olexa, Sheldon L. Epstein.

John G. Heimovics et al..

[ 57] ABSTRACT

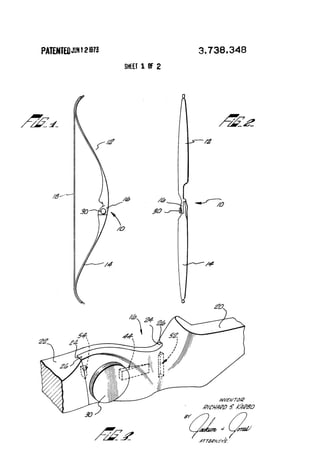

A take-down archery bow having a pair of bow limbs

with stepped interior ends which are adapted to be

locked in the mated position by a threaded bolt. The

lateral surfaces between the steps has an interengaging

ramp and incline combination which interacts to apply

a longitudinal force on the bow limbs to draw the

stepped ends of the bow limbs together as the bolt

draws the lateral surfaces together. A pair of interen

gaging boss and cut-out portions are also provided to

absorb a portion of the bending loads acting on the

limbs.

4 Claims, 5 Drawing Figures](https://image.slidesharecdn.com/breakdownbow-141119052732-conversion-gate01/85/Break-down-bow-10-320.jpg)

![as1}- . ,

‘a

United States Patent [191

Hoyt, Jr. I i -

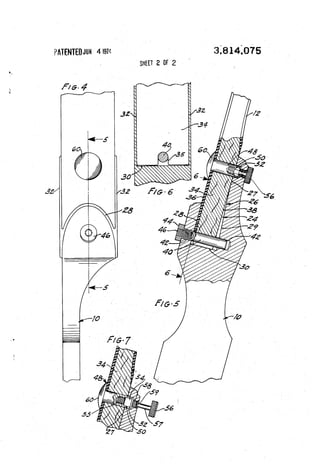

[111 3,814,075

[451 June 4,1974

[54]

[76]

[22]

[21]

[52]

[51]

[58]

l [561

TAKE DOWN ARCHERY BOW WITH A

MOUNT FOR A BOW STABILIZING

ELEMENT '

lnventor: Earl H. Hoyt, Jr., 1 l5 10 Natural

2,642,66l

3.265.055

3,326,200

3,527.196

Bridge Rd., Bridgeton, Mo. 65617

Filed: July 21, 1972

Appl. No.: 274,095

US. Cl. ........................... .. 124/24 R, 124/30 R

Int. Cl. ............................................ .. F4lb 5/00

Field of Search ..... 124/23 R, 24 R, 25, 22,

124/35, 41

References Cited

UNlTED STATES PATENTS

(3/1953 . Fredrickson .................... 124/23 R

8/l966 Gage ...........

6/l96'7 Grublc .......... ..

9/1970 Karl'm ............................. .. l24/24R

Priniary Examiner—Richard C. Pinkham

Assistant Examiner—William R. Browne

Attorney, Agent, or Firm—Charles E. Markham

[57] ABSTRACT

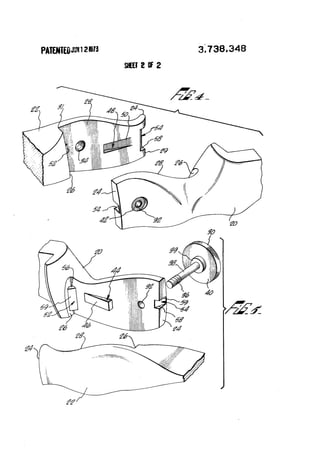

An archery bow with limbs detachably connected to a

handle section. The butt end portions of the limbs are

freely entered in close fitting relationship between lon

gitudinally spaced forward and rear wall portions of

sockets formed in the ends of- the handle section. A

?xed pin extending fore and aft across the bottom of

each socket engages a groove in the end of the limb

and a short stud projecting from the rear side of each

limb parallel with the ?xed pin and spaced from the

end of the limb enters a hole in the rear socket wall in

close ?tting relationship to position and hold the limbs

, in lateral alignment. A thumb screw extends through

the rear wall of each socket and is threadedly engaged

in the short projecting studs to clamp the limbs to the

rear socket walls. The forward socket walls are shorter

than the rear walls and a portion of each rear socket

wall near the bottom is relieved to permit entry of the

limbs in a slightly forward tilted position thereby to

permit free entry of the limbs between the socket wall

portions and to permit entry of the short projecting

studs. .'

9 Claims, 7 Drawing Figures](https://image.slidesharecdn.com/breakdownbow-141119052732-conversion-gate01/85/Break-down-bow-13-320.jpg)

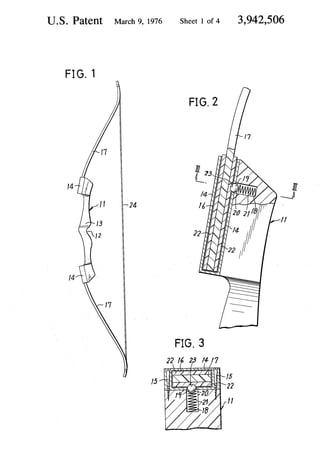

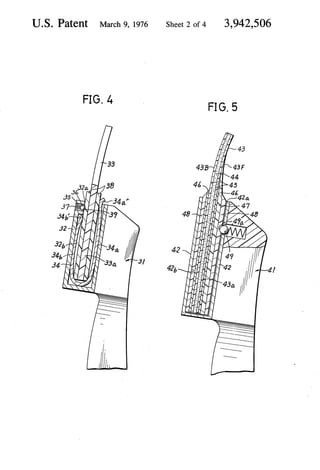

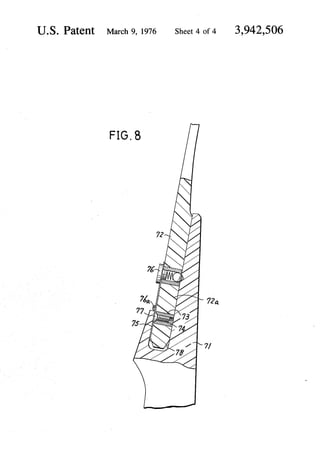

!['United States Patent [191 [111 3,942,506

lzuta [45] Mar. 9, 1976

[54] DEMOUNTABLE ARCHERY BOW 3,814,075 6/1974 Hoyt ............................... .. 124/24 R

[75] Inventor: Tadao lzuta, Hamamatsu, Japan

[73] Assignee: Nippon Gakki Seizo Kabushiki

Kaisha, l-lamamatsu, Japan

[22] Filed: June 20, 1974

[21] Appl. No.: 481,403

[52] US. Cl. ........ .1 .... .-. ........... .. 124/24 R; 124/30 R

[51] Int. Cl.2 ............................ ..- ............ .. F4-1B 5/00

[58] Field of Search ...... .. 124/23 R, 24 R, 30 R, 25,

124/22, 30 A, 52; 279/79, 85

[56] References Cited

UNITED STATES PATENTS

2,476,762 7/1949 Petre et a1. ..................... .. 279/79 X

~ 2,522,388 9/1950 Madsen . . . . . . . . . . . . . . . . .. 279/79 X

2,562,462 7/1951 Jackson . . . . . . . . . . . . . . . . . . . .. 124/52

2,580,930 1/1952 Kost .................................... .. 279/79

2,958,552 11/1960 Vosbikian et al ............... .. 279/79 X

2,972,493 2/1961 Waters ............................ .. 279/79 X

3,415,240 12/1968 Bear . . . . . . . . . . . . . . . . .. 124/23 R

3,628,519 12/1971 l-lofmeister .................. .. 124/24 R

3,695,248 10/1972 lzuta ............................... .. 124/24 R

Prim-my Examiner-Anton O. Oechsle

Assistant Examiner-William R. Browne

Attorney, Agent, or Firm-Haseltine, Lake_& Waters

[57] ABSTRACT

A demountable archery bow with a handle provided at

the opposite ends thereof with limb receiving means,

and limbs to be removably inserted in the respective

limb receiving means. A click stop mechanism is pro

vided between each limb receiving means and the as

sociated limb to facilitate the assembly and disassem

bly of the handle and limbs. The click stop mechanism

may have a recess formed on the limb side in a man

ner to open in a direction perpendicular to that in

which the limb is inserted in the limb receiving means,

and a spring biased ball provided on the handle side,

the ball being received in the recess under the spring

biasing force when the limb is inserted in the handle

and the ball being forcedly removable from the recess

when a force pulling the limb away from the handle is

exerted on the limb.

4 Claims, 8 Drawing Figures

T 724](https://image.slidesharecdn.com/breakdownbow-141119052732-conversion-gate01/85/Break-down-bow-16-320.jpg)

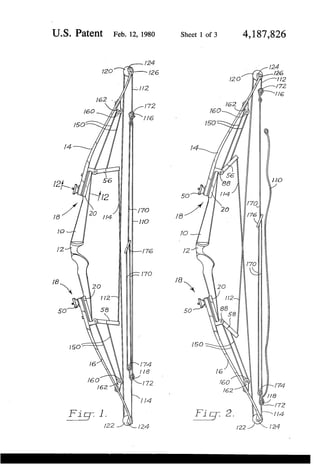

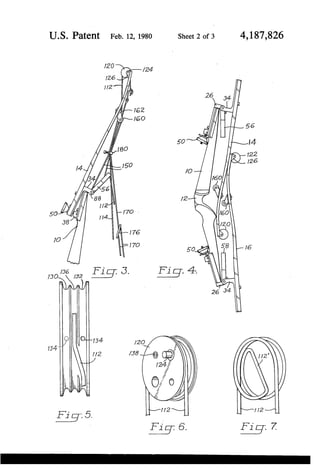

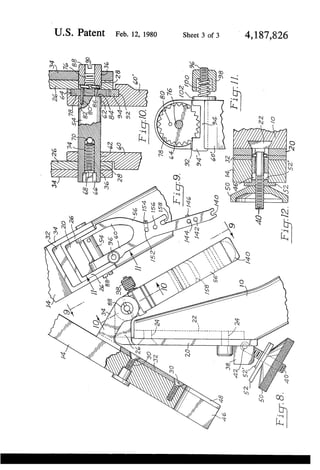

![United States Patent [191

Killian

[11] 4,187,826

[45] Feb. 12, 1980

[54] FOLDING LIMB COMPOUND ARCHERY

BOW

[76] Inventor: Gerald I. Killian, 16016 SE. 82nd Dr.,

Clackamas, Oreg. 97015

[21] Appl. No.: 787,860

[22] Filed: Apr. 15, 1977

[51] Int. Cl.2 . . . . . . . . . . . . . . . . . . .. F41B 5/00

[52] US. Cl. .................................. .. 124/24 R; 29/235;

124/88

[58] Field of Search ................ .. 124/23 R, 24 R, 90,

124/88, 86; 403/12; 24/1226, 135 N, 135 R;

29/235

[56] References Cited

U.S. PATENT DOCUMENTS

3,207,145 9/ 1965 Browning et al. ............... .. 124/23 R

3,253,587 ' 5/ 1966 Pearson .................... .. 124/23 R

3,294,078 12/ 1966 Allen .... .. 124/23 R

3,352,296 11/1967 Burger .. .... .. 124/23 R

3,486,495 12/ 1969 Allen 124/ 24 R

3,841,295 10/1974 Hunter .. .. 124/24 R

3,957,027 5/1976 Drake .... .. 124/23 R

4,050,137 9/ 1977 Carlson ................................ .. 29/235

FOREIGN PATENT DOCUMENTS

708863 7/ 1941 Fed. Rep. of Germany ........ .. 24/ 122.6

Primary Examiner—Richard C. Pinkham

Assistant Examiner—William R. Browne

Attorney, Agent, or Firm—James E. Nilles

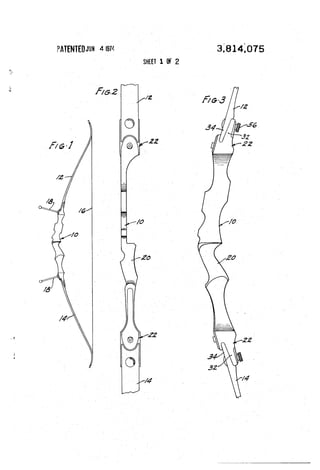

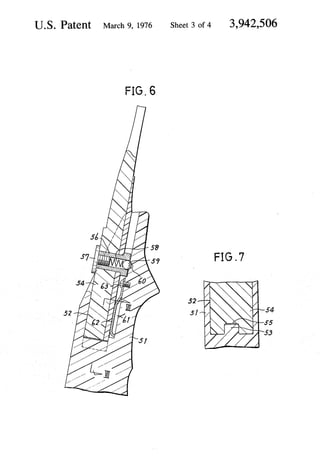

[57] ABSTRACT

A compound archery bow has resilient limbs pivotally

attached to the opposite ends of a central handle by

hinges allowing the limbs to be folded between an oper

ative position and a folded position. The limbs are re

leasably secured in an operation position by a latch

mechanism. A secondary cable interconnects each limb

and a tensioning lever on the handle for adjustably

pre-tensioning the limbs. A ratchet shaft assembly piv

otally mounts the tensioning levers and allows the ten

sion of each limb to be adjusted. The limbs can be re

laxed by lengthening a stringer, whereupon the latch

mechanism can be opened, allowing the limbs to be

released and pivoted on the hinges to their folded posi

tion adjacent the belly side of the bow. Cam members

are mounted at the outer end of each limb and around

which the end segments of the bow string are wrapped

at least about 270° in each direction. Thus the cam mem

bers can be reversibly rotated to accommodate either

tensioning of the bow for projecting an arrow, or relax

ing of the bow for release of the limbs. As a result the

bow may be folded and unfolded without altering its

pre-established tension characteristics.

9 Claims, 12 Drawing Figures](https://image.slidesharecdn.com/breakdownbow-141119052732-conversion-gate01/85/Break-down-bow-21-320.jpg)

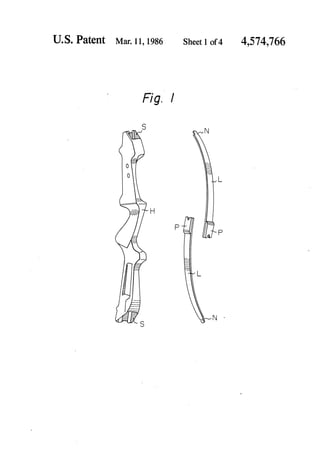

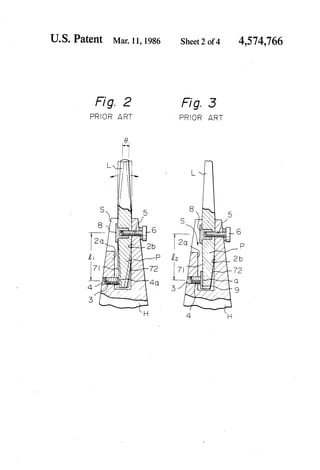

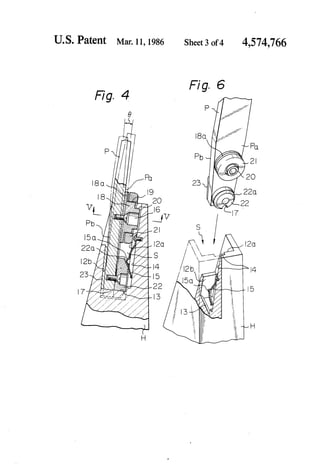

![United States Patent [19]

Izuta

4,574,766

Mar. 11, 1986

[11] Patent Number:

[45] Date of Patent:

[54] JOINT STRUCTURE OF A TAKE-DOWN

TYPE ARCHERY BOWS

[75] Inventor:

[73] Assignee:

Tadao Izuta, Hamamatsu, Japan

Nippon Gakki Seizo Kabushiki

Kaisha, Japan

[21] Appl. N0.: 404,291

[22] Filed: Aug. 2, 1982

[30] Foreign Application Priority Data

Aug. 6, 1981 [JP] Japan ......................... .. 56-117220[U]

[51] Int. Cl.4 .............................................. .. F41B 5/00

[52] US. Cl. ................................ .. 124/23 R; 124/88

[58] Field of Search .......... .. 124/23 R, 24 R, DIG. 1,

‘ 124/88, 86

[56] References Cited

U.S. PATENT DOCUMENTS

261,610 7/1882 Howe .............................. .. 124/23 R

3,262,442 7/1966 Grable 124/24 R

3,415,240 12/1968 Bear ..... .. 124/23 R

3,757,762 9/1973 Cousin 124/24 R

3,766,904 10/1973 Izuta .................... .. 124/24R

3,874,360 4/1975 Armstrong et a]. 124/23 R

3,921,598 11/1975 Helmick .......................... .. 124/24R

3,957,027 5/1976 Drake ............................. .. 124/23R

FOREIGN PATENT DOCUMENTS

114300 lO/l978 Japan .............................. .. 124/23 R

Primary Examiner—Richard J. Apley

Assistant Examiner—William R. Browne

Attorney, Agent, or Firm—Lerner, David, Littenberg,

Krumholz & Mentlik

[57] ABSTRACT

A joint structure between each limb and a handle riser

of a take-down type archery bow is described employ

ing a plug-socket engagement based upon a two posi

tion support. The ?rst position support is located near

the mouth of a handle riser socket and enables the

change in angular position of the limbs with respect to

the handle riser by the replacement of a pair of flat

spacers of predetermined thickness. The second posi

tion support, being unaffected by the ?rst position sup

port, is located near the bottom of the socket for releas

ably engaging the plug end of the limbs in order to

prevent accidental removal of the limbs from the handle

riser socket.

4 Claims, 9 Drawing Figures](https://image.slidesharecdn.com/breakdownbow-141119052732-conversion-gate01/85/Break-down-bow-25-320.jpg)

![United States Patent [19]

Izuta

[54] JOINT STRUCTURE OF A TAKE-DOWN

TYPE ARCHERY BOW

[75] Inventor:

[73] Assignee:

Tadao Izuta, Hamamatsu, Japan

Nippon Gakki Seizo Kabushiki

Kaisha, Japan

[21] Appl.No.: 801,001

[22] Filed: Nov. 22, 1985

Related US. Application Data

[62] Division of Ser. No. 404,291, Aug. 2, 1982, Pat. No.

4,574,766.

[30] Foreign Application Priority Data

Aug. 6, 1981 [JP] Japan ......................... .. 56-ll7220[U]

[51] Int. Cl.4 ............... .. F41B 5/00

[52] US. Cl. ............................... .. 124/23 R; 124/ 88

[58] Field of Search .......... .. 124/23 R, 24 R, DIG. l,

124/88

[56] References Cited

U.S. PATENT DOCUMENTS

3,874,360 4/1975 Armstrong et a1. ............. .. 124/23 R

1

i

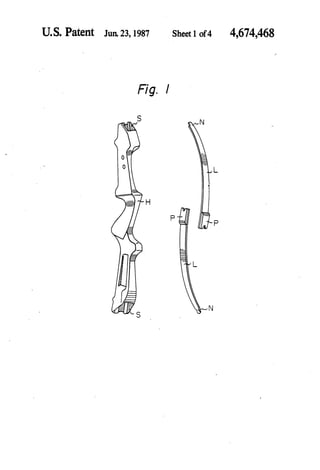

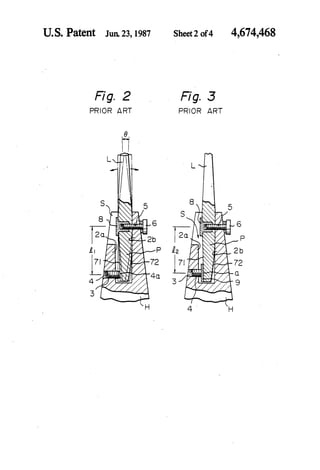

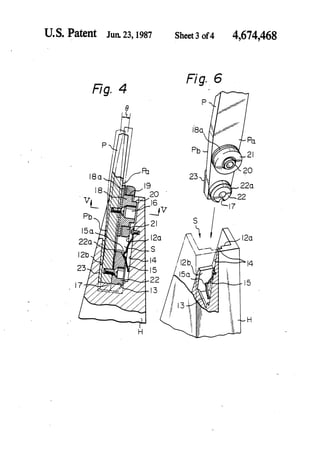

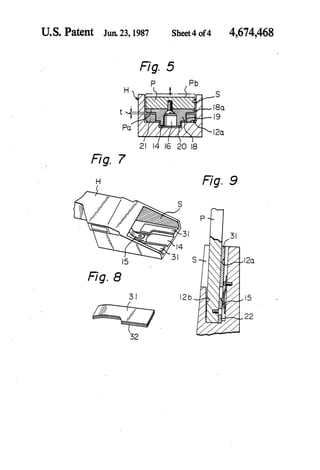

[11] Patent Number: 4,674,468

[45] Date of Patent: Jun. 23, 1987

3,921,598 11/1975 Helmick .......................... .. 124/24R

3,942,506 3/1976 Izuta ............................... .4 124/24R

Primary Examiner—Richard C. Pinkham

Assistant Examiner—Benjamin Layno

Attorney, Agent, or Firm—Lerner, David, Littenberg,

Krumholz & Mentlik

[57] ABSTRACT

In a joint structure between each limb and a handle riser

of a knock-down type archery bow employing a plug

socket engagement, a two position support is formed by

a pair of separate supporter pieces ?xed to the face side

of the socket, one supporter piece located closer to the

socket mouth forming the ?rst support for enabling

change in angular position of the limb with respect to

the handle riser, and the other supporter piece located

closer to the socket bottom forming the second support

unmoved by any change in the ?rst support. The ab

sence of holes in the socket walls assures a strong con

struction without the increase in weight, and the adjust

ment by the ?rst support causes no disturbance on the

originally designed balance of force over the entire

construction.

3 Claims, 9 Drawing Figures](https://image.slidesharecdn.com/breakdownbow-141119052732-conversion-gate01/85/Break-down-bow-30-320.jpg)

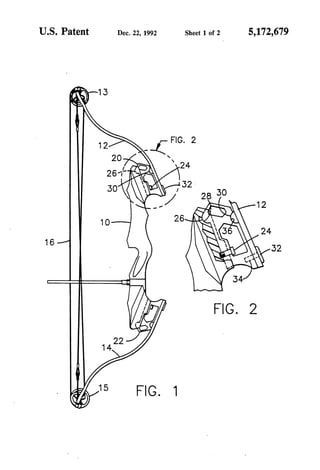

![IllllllllllllllllIllllIlllllllllllllllllllIllllIlllllllllllllllllllllllllll

US005172679A

United States Patent [19] [11] Patent Number: 5,172,679

Mussack [45] Date of Patent: Dec. 22, 1992

[54] MODULAR CONSTRUCTION FOR [56] References Cited

COMPOUND ARCHERY BOW us. PATENT DOCUMENTS

75 I t l - ' - - 3,821,946 7/1974 [ ] nven or geggn R Mussack, Clifton Springs, 3184x195 10/1974

' ' 3,942,506 3/1976

. 4,064,862 12/1977

[73] Asstgnee: Golden Eagle Archery, Inc., 4,261,320 4/1981

Farmington, NY. 4,574,766 3/1986

. Primary Examiner—Peter M. Cuomo

[211 App]' No" 749’312 Attorney, Agent, or Fz'rm—Hoffrnan Stone

[22] Filed: Aug. 23, 1991 [57] ABSTRACT

A modular construction for compound archery bows

R l d U s A l, _ includes sets of spacer blocks for insertion between the

6 ate ' ' pp ‘canon Data bow handle and the limbs. The blocks are shaped to

[63] Continuation-impart of Ser. No. 569,868, Aug. 20, provide selected variations in the geometry of the bows,

1990, abandoned. selectively adjusting the brace height and the overall

length of the bow. The manufacturer is enabled to cre

[51] Int. Cl.5 .............................................. .. F41B 5/00 ate bOWs of many different characteristics without in

[52] U.S. Cl. ................................ .. 124/25.6; 124/23.1; vesting in dies to produce differently shaped handles,

124/88 needing only differently shaped spacer blocks.

[58] Field of Search ..................... .. 124/88, 25.6, 23.1, ‘

124/ 24.1, 86 3 Claims, 2 Drawing Sheets

14

22](https://image.slidesharecdn.com/breakdownbow-141119052732-conversion-gate01/85/Break-down-bow-35-320.jpg)

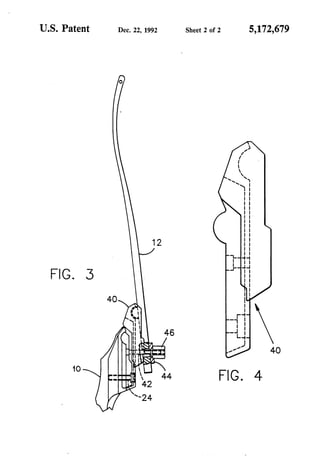

![llllllllllllllllllllllll|||llllllllllfllllllllllllllllllllllllllllllllllllll US005 6923A

Unlted States Patent [19] [11] Patent Number: 5 546 923 9 9

Duncan [45] Date of Patent: Aug. 20, 1996

[54] TAKE-DOWN ARCHERY BOW 3,942,506 3/1976 Izuta .

3,957,027 5/1976 Drake ...................................... .. 124/88

[76] Inventor: Douglas J. Duncan, 8157 Budworth 4,091,790 5/1973 Hoyt, Jr- -

School Rd., PO. Box 742, Beetown, ill‘?

' , , zu a .

WIS‘ 53802 4,693,230 9/1987 Sugouchi ................................ .. 124/88

4,793,319 12/1988 Vaughan et a1..

[21] Appl. No.: 330,831 5,025,774 6/1991 Martin ..................................... .. 124/89

. 5,280,779 1/1994 Smith 124/88

[22] F1169: , Oct- 27’ 1994 5,291,874 3/1994 Harrison .............................. ..-. 124/23.1

6

------------------------------------------------------ .

[52] US. Cl. . . . . . . . . . . . . . . . . . . . . . . . .. 124/23.1

[58] Field of Search ................................ .. 124/23.1, 24.1, Traditional BOW/hunter, NO- 76695, Aug/5994 1993, PP

124/25.6, 86, 88; 403/393 4647

[56] References Cited Primary Examiner—-Eric K. Nicholson

Assistant Examiner—-J0hn A. Ricci

U.S. PATENT DOCUMENTS Attorney, Agent, or Firm-Arrnstrong, Westerman, Hatton',

261,610 7/1882 Howe. McLeland 8‘ Naughton

1,709,630 4/ 1929 Rounsevelle ......................... .. 124/231

2,125,591 8/1938 Smith. [57] ABSTRACT

gelm .................................. .. 124/23.1 An archery bow having a belly and a back and comprising

, , owar . - 2,813,818 11/1957 Pearson ............................ .. 1241231 X two elopgated branch .cqmponems each having a.“ and’ the

3 156 230 1m964 Groves ends being detachably JOlIlCd together at a]o1ntw1th at least

3,527,196 9/1970 Kal'bO ................. . . 124/241 one releasable fastener- The joint is de?ned by mating

3:612:028 10/1971 Karbo _ """"""" ' ' ' surfaces on the ends of each component and is between the

3,733,343 6/1973 Karbo _ belly and the back of the bow. The mating surfaces of each

3,766,904 10/1973 Izuta . component have a ?rst curved surface extending to the bow

3,771,508 11/1973 Black et a1. . belly and a second curved surface extending to the bow

3,814,075 6/1974 Hoyt, Jr. . back.

3,821,946 7/1974 Griggs.

3,874,360 4/1975 Annstrong et a1. .

3,921,598 11/1975 Helmick . 18 Claims, 1 Drawing Sheet

22](https://image.slidesharecdn.com/breakdownbow-141119052732-conversion-gate01/85/Break-down-bow-38-320.jpg)

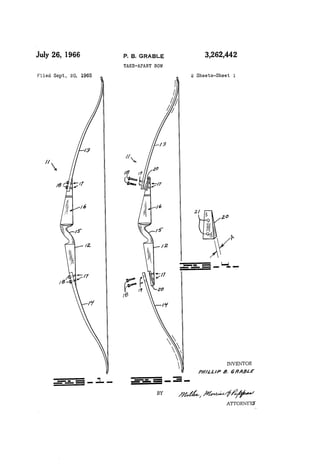

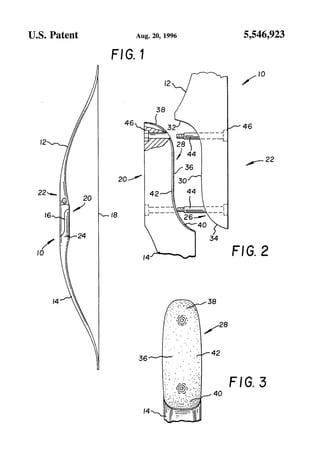

![United States Patent [19]

Cox et al.

US006019097A

6,019,097

Feb. 1, 2000

[11] Patent Number:

[45] Date of Patent:

[54] DE-TENSIONING AND BREAKDOWN

SYSTEM FOR A COMPOUND BOW

[76] Inventors: Jimmie D. Cox, 18701 Vierra Canyon

Rd., Salinas, Calif. 93907; Douglas T.

Bresette, 45 Rialto Dr., Watsonville,

Calif. 95076

[21] Appl. N0.: 09/096,859

[22] Filed: Jun. 12, 1998

[51] Int. Cl.7 .. .............. .. F41B 5/00

[52] US. Cl. ................ .. . 124/23.1; 124/25.6

[58] Field of Search ............................ .. 124/1, 23.1, 25.6,

124/86, 88

[56] References Cited

U.S. PATENT DOCUMENTS

2,228,823 1/1941 Helm .................................... .. 124/231

2,514,638 7/1950 Grenier 124/231

3,156,230 11/1964 Groves . . . . . . . . . . . . . . . . . . .. 124/231

4,291,452 9/1981 Whitman et a1. .. 124/231 X

4,599,987 7/1986 ReZmer . . . . . . . . . . . . . . . . . .. 124/231

5,125,389 6/1992 Paff . . . . . . . . . . . .. 124/86

5,746,192 5/1998 Gissel ........................................ .. 124/1

Primary Examiner—John A. Ricci

ll

Attorney, Agent, or Firm—Milton Wolson

[57] ABSTRACT

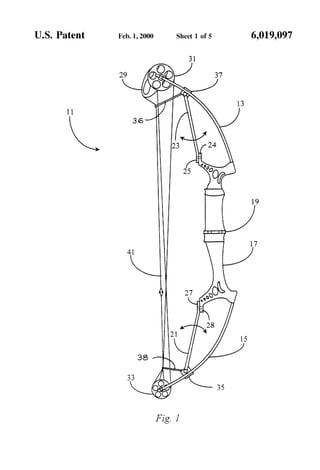

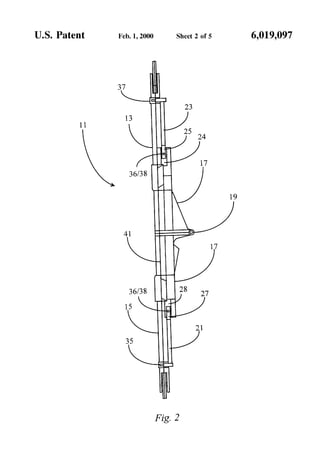

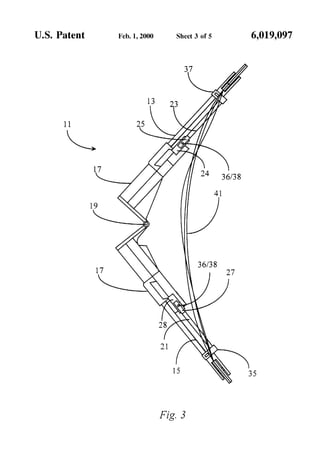

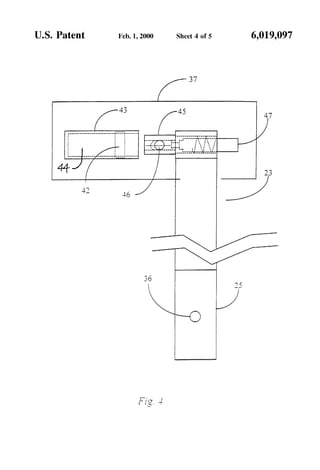

A foldable archery bow has a center section and tWo ?exible

arms extending in substantially opposite directions, describ

ing a boW plane, and a separation interface disposed in the

center section and positioned to alloW the boW to be sepa

rated into to separate sections. At least one latching connec

tor is attached to a ?rst point on one of the ?exible arms, and

is adapted, When the ?exible arm to Which it is attached is

substantially ?exed, to latch at a second point on the same

side of the separation interface as the ?rst point. By drawing

the boW, Which ?exes the ?exible arms, and latching the

latching connector, all tension is released from the boW

string or strings, and all forces thereby removed from the

separation interface. The separation interface, normally fas

tened in a closed position, may then be unfastened and

separated, alloWing the boW to divide into the tWo separate

sections forming a smaller package than in the assembled

aspect. The boW may be again set up by aligning and

refastening the separation interface, drawing the boW, and

unlatching the connector, restoring the same tension to the

how that it had before folding. In some embodiments a hinge

is employed at the separation interface, alloWing the boW to

fold, and a variety of force removal mechanisms are taught.

12 Claims, 5 Drawing Sheets](https://image.slidesharecdn.com/breakdownbow-141119052732-conversion-gate01/85/Break-down-bow-40-320.jpg)