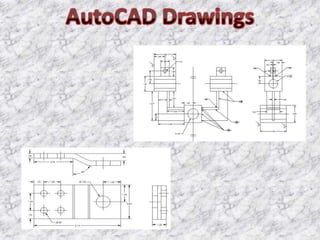

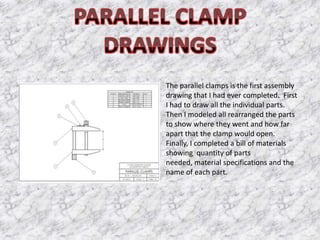

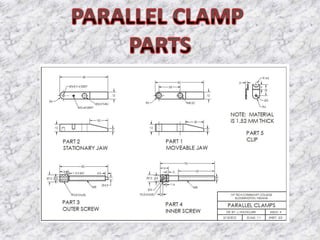

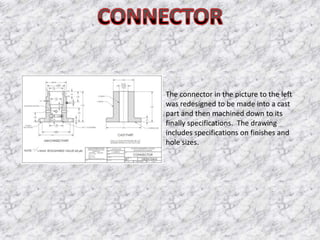

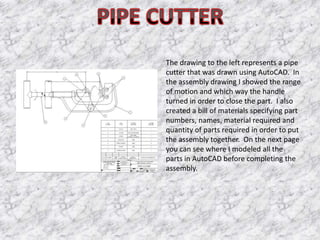

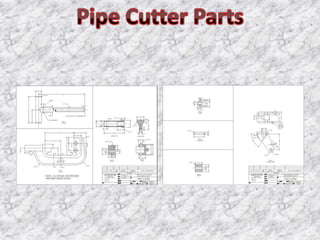

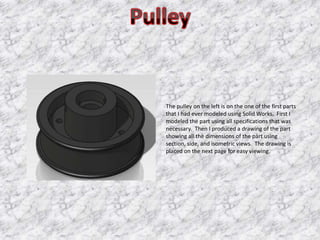

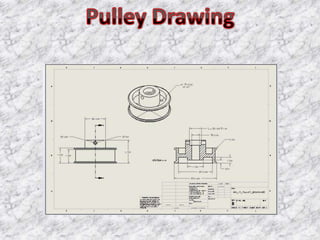

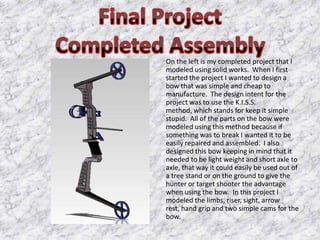

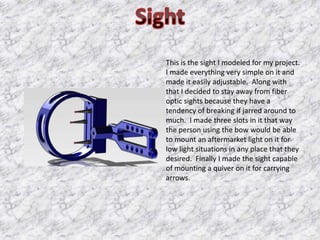

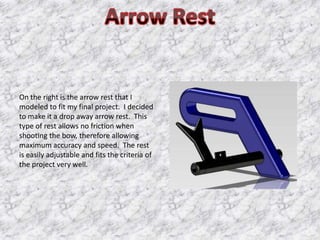

The document summarizes the modeling and design of several mechanical parts and assemblies created using CAD software like AutoCAD and SolidWorks. It describes modeling individual parts, assemblies, and drawings for a parallel clamp, connector, pipe cutter, pulley, bracket, sheet metal objects, and a bow with limbs, riser, sight, arrow rest, and cams. Details like dimensions, specifications, features used, and design intent are discussed for each part or project.