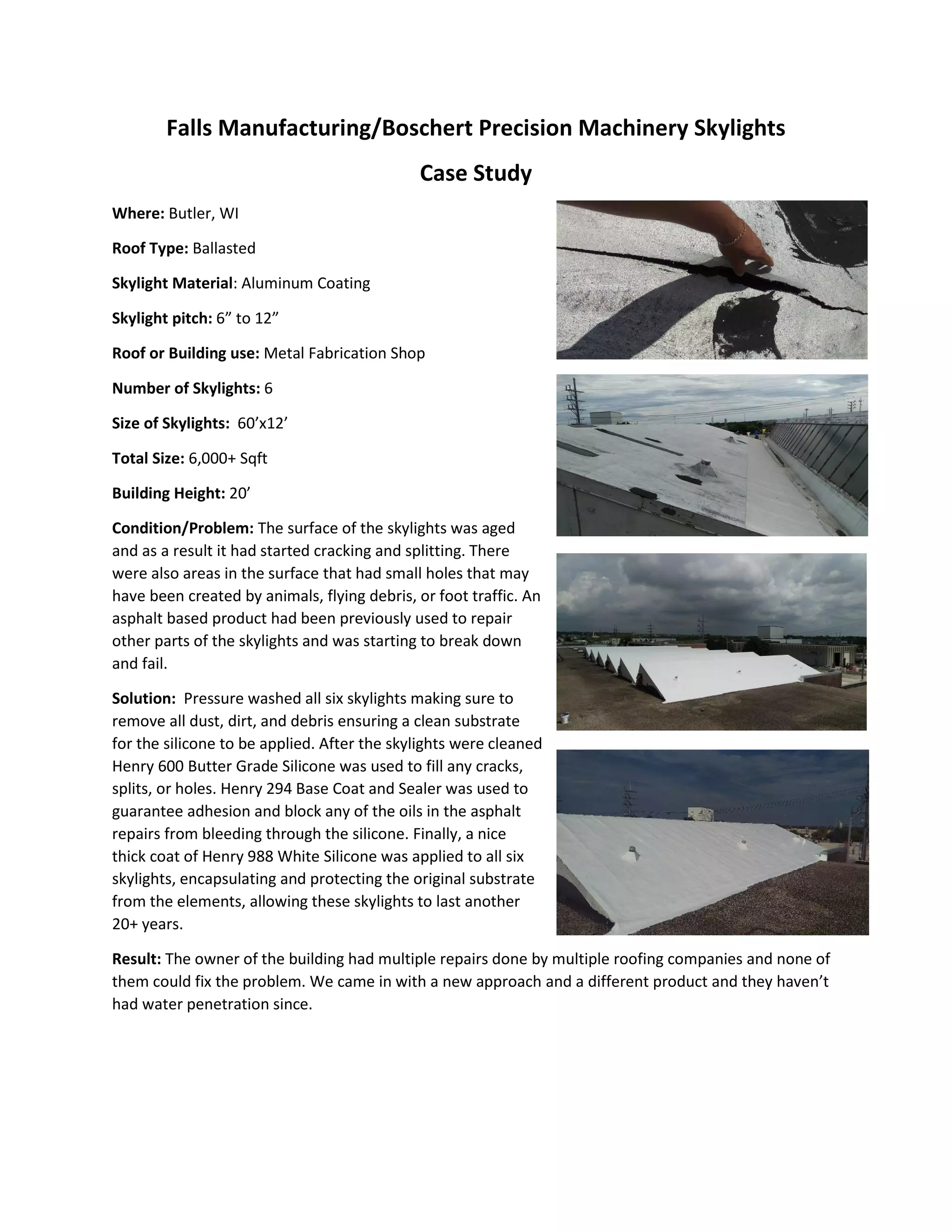

The skylights at a metal fabrication shop in Butler, WI were aged and cracking, with small holes from animals, debris or traffic. Previous asphalt repairs were failing. The skylights were pressure washed, cracks and holes filled with silicone, a base coat applied to block asphalt oils, and then a thick coat of white silicone to encapsulate and protect the substrate for 20 more years of use. This new silicone approach successfully solved the water penetration issues that previous roofing companies were unable to fix.