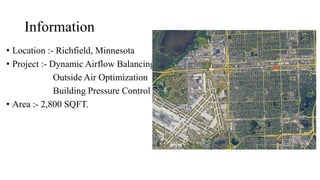

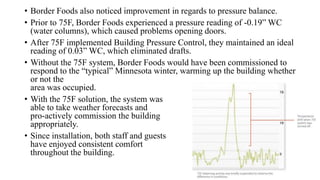

This document discusses a case study of how CCMS (Central Control and Monitoring System) technology was used to solve temperature imbalance issues at a Border Foods restaurant in Minnesota. The CCMS system from 75F used sensors and cloud-based algorithms to automatically balance airflow and adjust temperatures throughout the restaurant kitchen and dining area in response to outside weather and solar conditions. This created a more uniform and comfortable environment for employees and customers. The CCMS system also helped the restaurant maintain optimal positive pressure levels.