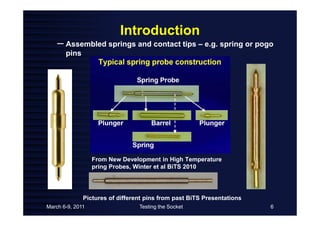

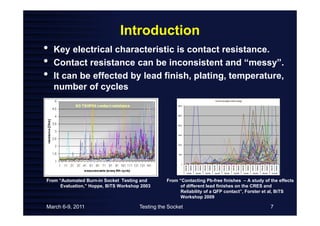

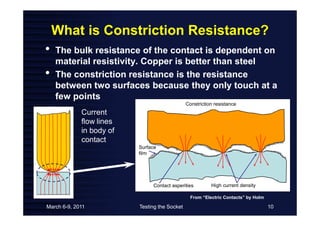

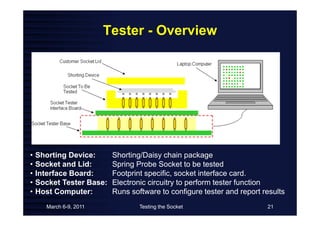

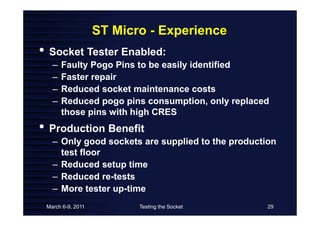

The document discusses the importance of verifying socket functionality, particularly focusing on contact resistance (CRES) as a critical characteristic for ensuring test socket reliability and performance. It outlines causes of variation in contact resistance, methods for measuring it, and the impact of CRES on productivity and costs in manufacturing environments. Additionally, it presents the CR-2600 tester as a solution for validating socket integrity and improving operational efficiency by monitoring pin performance.