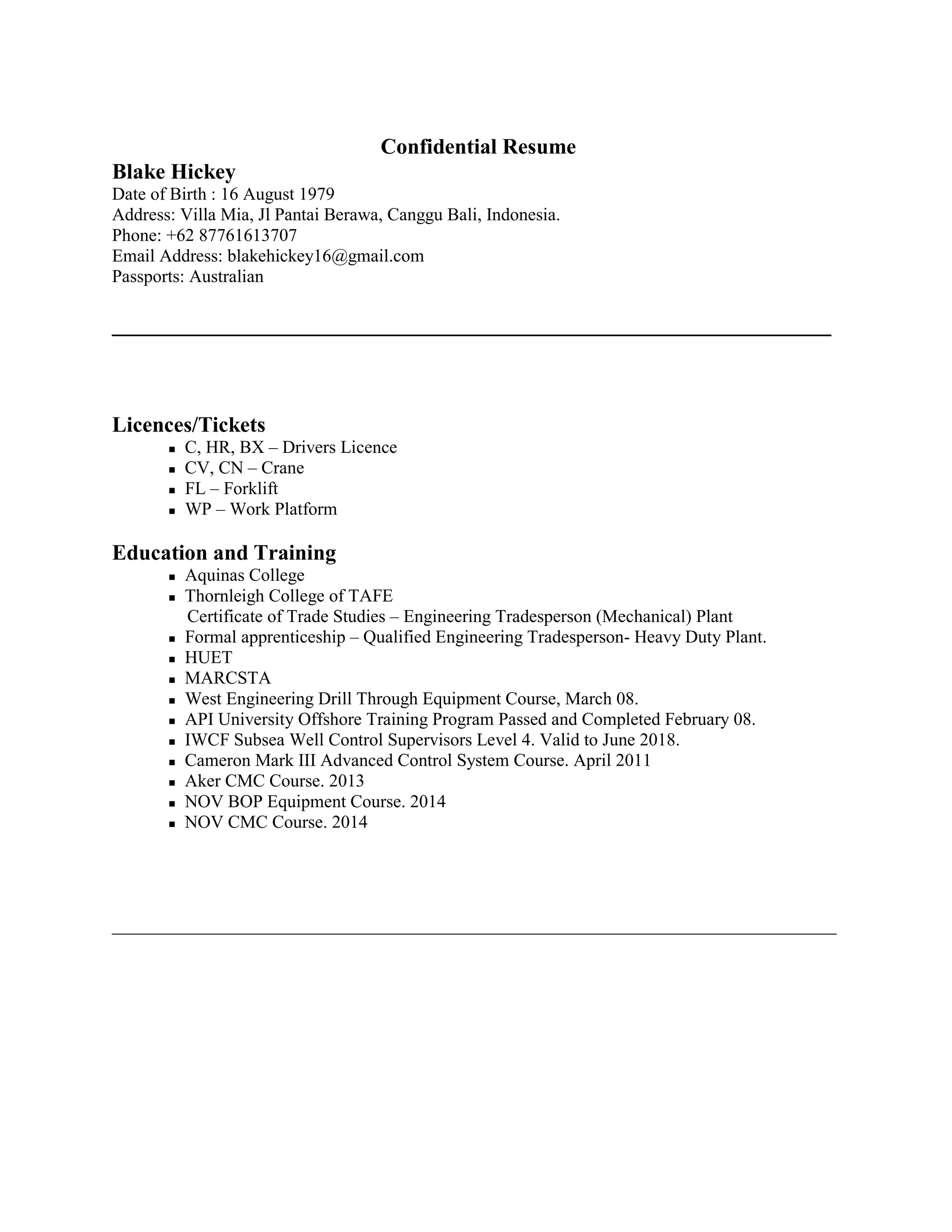

This document is a confidential resume for Blake Hickey. It provides personal details and contact information, as well as a detailed work history in subsea equipment maintenance and offshore drilling roles from 2002 to present. Hickey has experience with various subsea blowout preventers, control systems, risers and other well control equipment. The resume lists education and licenses and provides references.