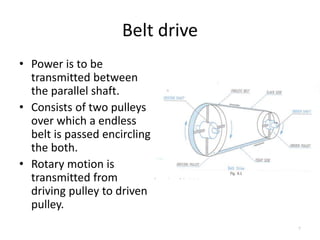

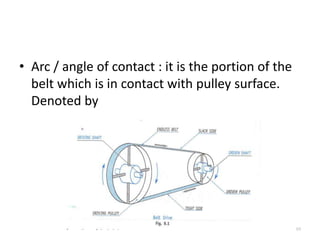

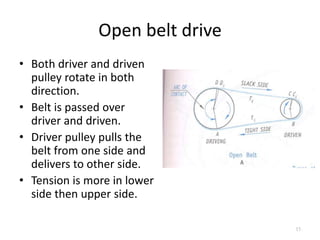

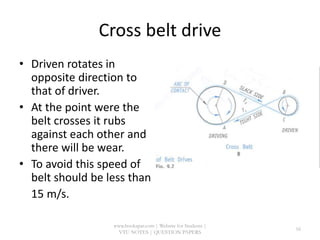

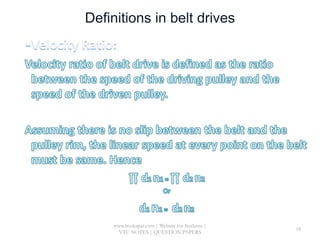

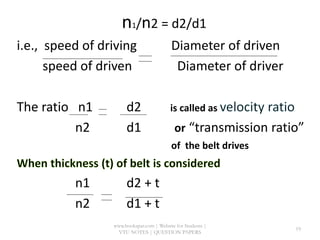

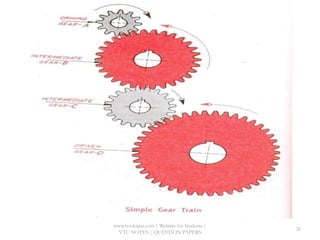

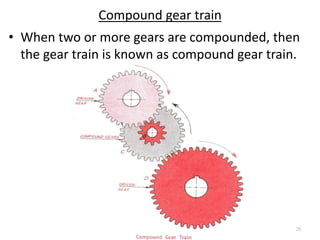

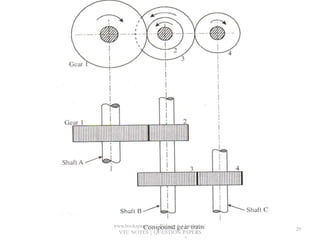

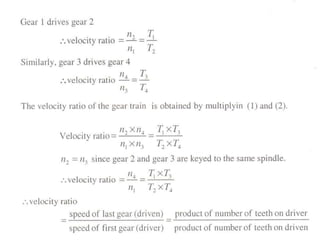

This document discusses different types of power transmission systems, including belt drives, rope drives, chain drives, and gear drives. It focuses on belt drives, describing the key components of belt drives like pulleys, belts, and different belt configurations. The document compares open and closed belt drives. It also discusses factors to consider when selecting a transmission system like the distance between shafts, operating speeds, and power requirements. Gear trains are also introduced, including simple and compound gear trains. The summary provides an overview of the main transmission system types covered in the document.