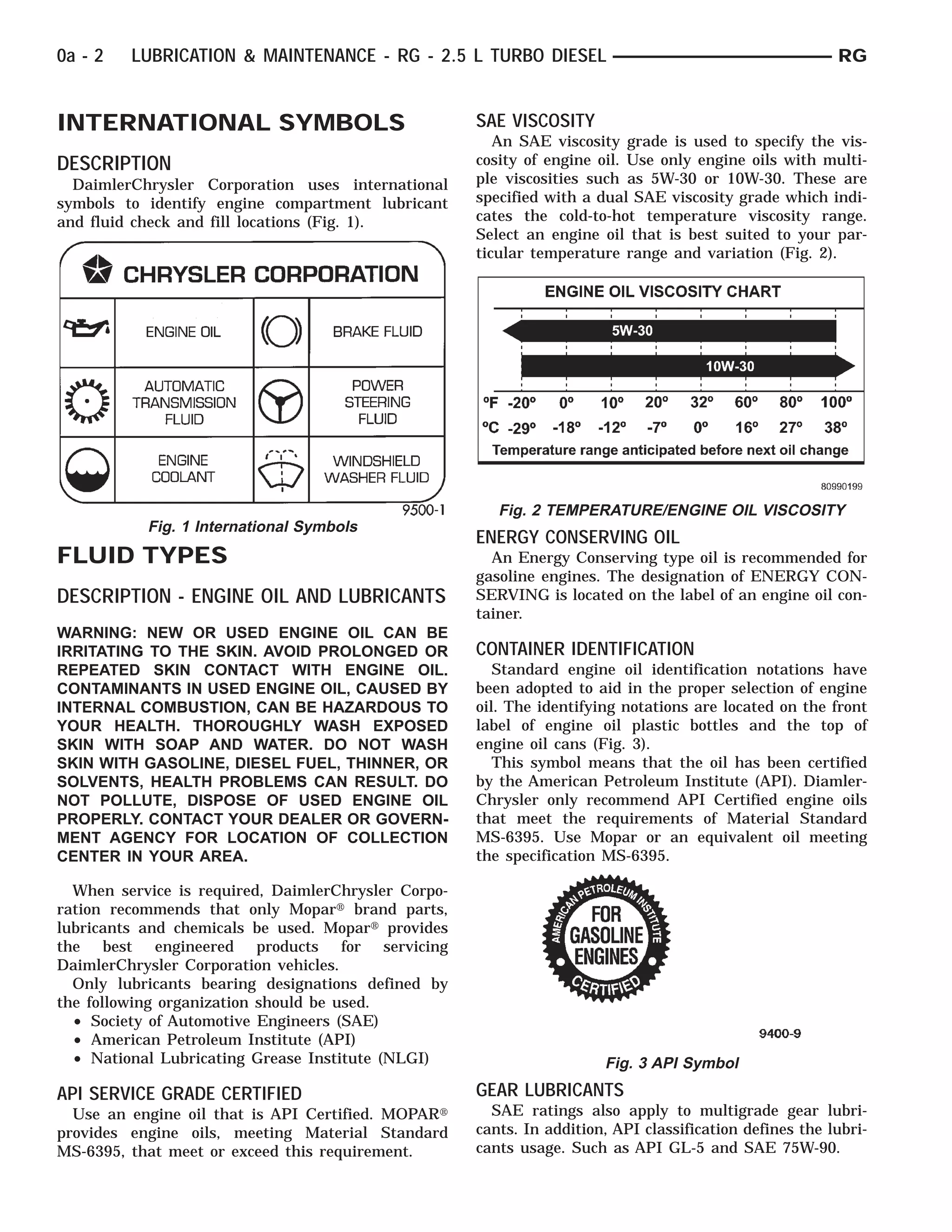

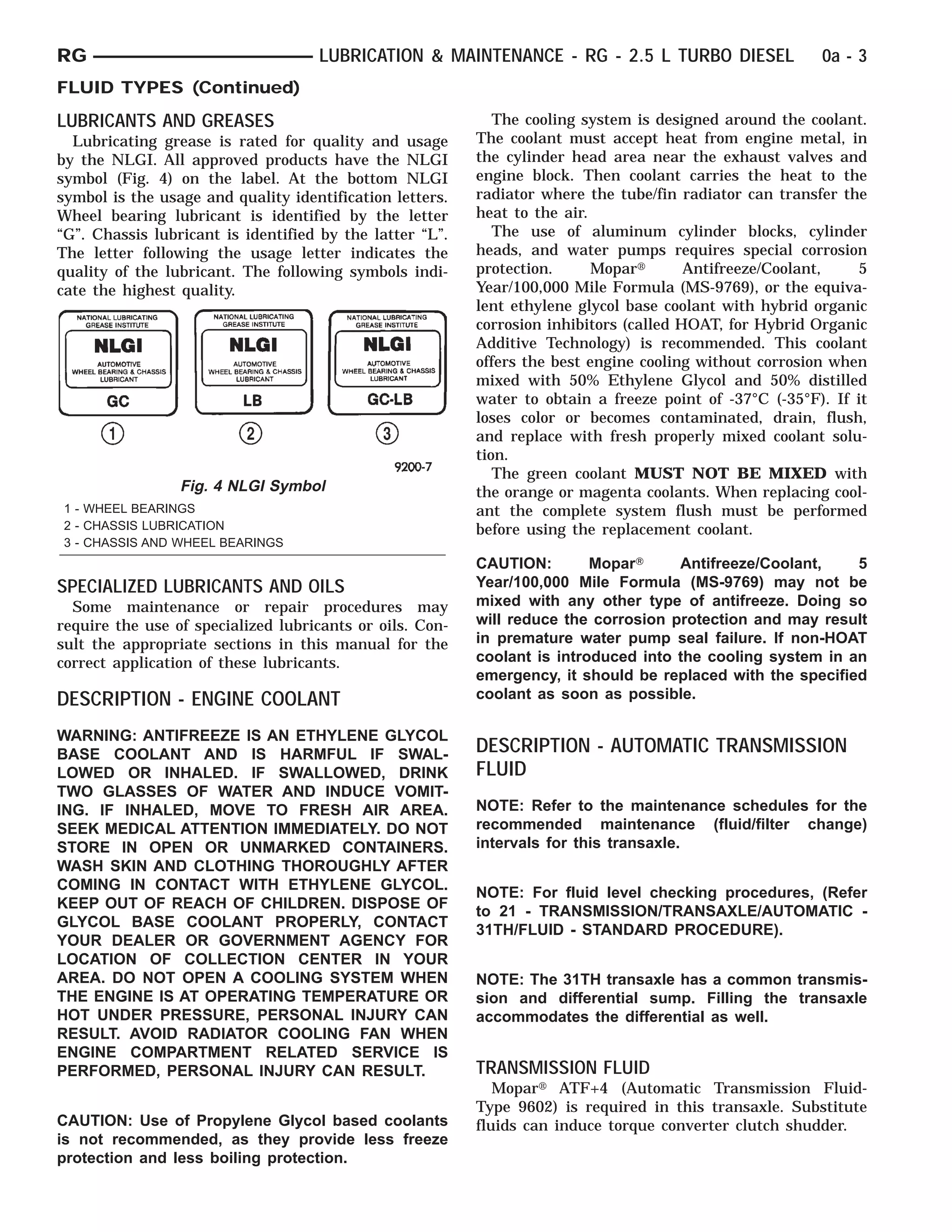

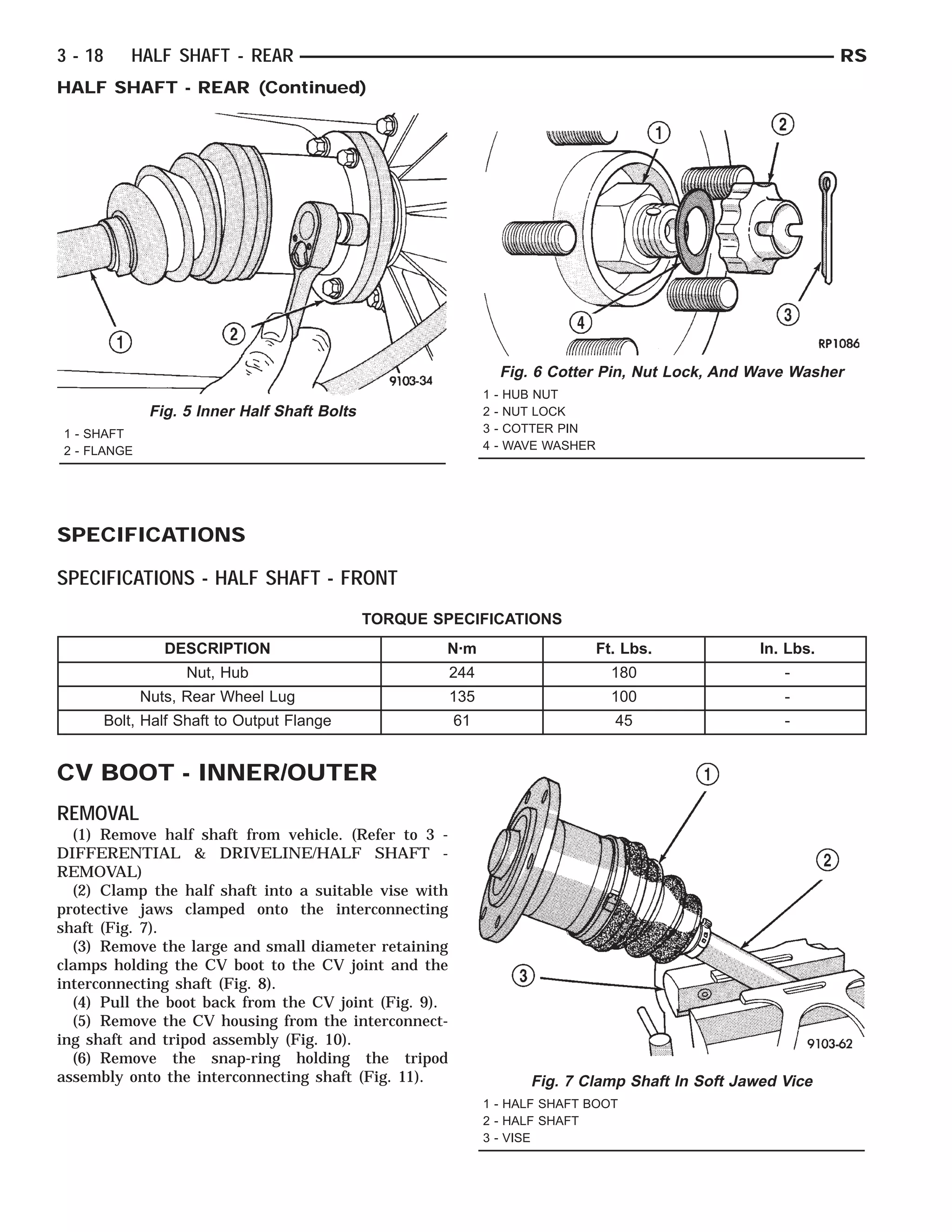

The document is a detailed technical guide covering various aspects of vehicle maintenance, including lubrication, brakes, engine systems, and more. It includes descriptions and specifications for vehicle identification, safety certification labels, fasteners, and torque references among others. Additionally, it provides information on international symbols for vehicle controls and conversion charts between metric and English systems.