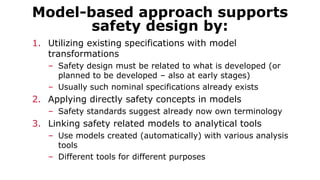

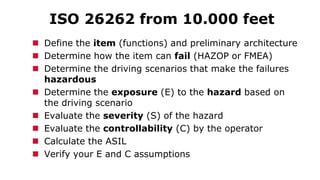

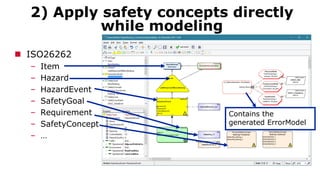

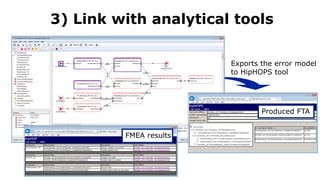

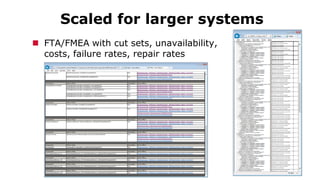

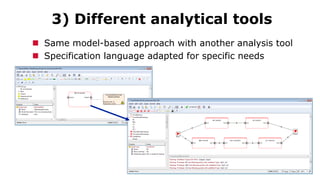

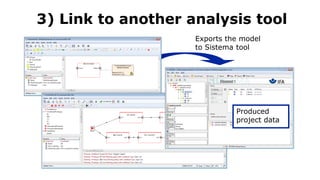

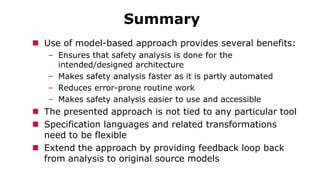

The document discusses automating safety engineering using model-based techniques to enhance efficiency and reduce manual efforts. It outlines the motivation behind such an approach, including the application of existing specifications and linking safety-related models to analytical tools. The proposed method aims to streamline safety analysis, making it faster, less error-prone, and easier to use, while remaining adaptable to various tools and languages.