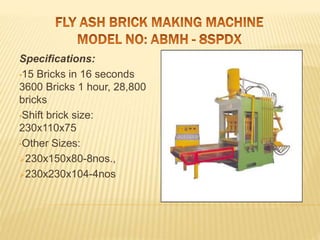

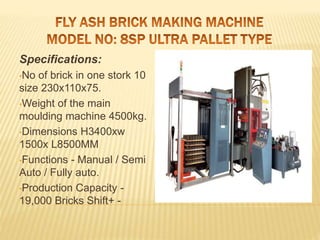

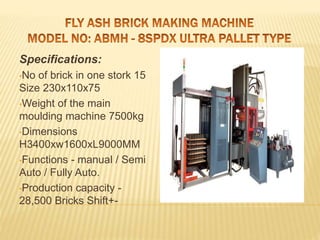

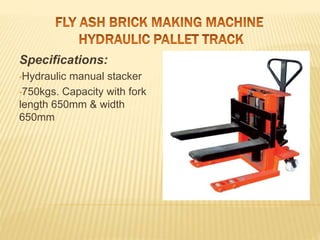

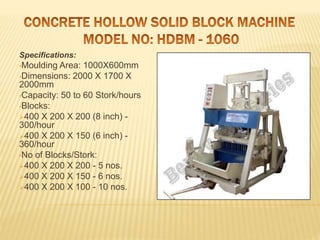

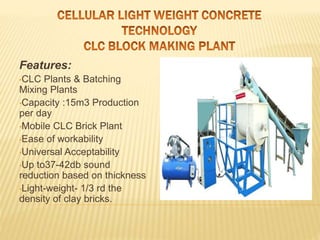

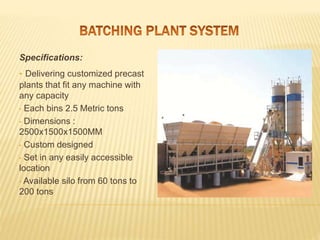

Benny Industries, established in 1975 and ISO 9001:2000 certified, manufactures and exports machinery for the construction industry, including various types of block and brick making machines. With a state-of-the-art manufacturing unit and experienced professionals, they offer automatic and manual plants tailored to client needs, boasting impressive production capacities and customizable specifications. The company is committed to delivering high-quality products such as fly ash brick machines, concrete paver machines, and lightweight CLC plants, among others.