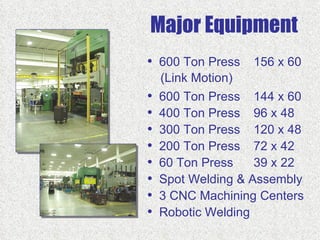

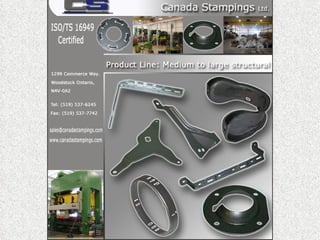

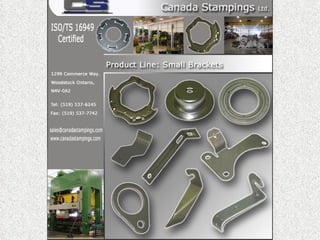

Canada Stampings Ltd. is a metal forming company founded in 1898 that was purchased by the Hewitt family in 1965. It has since expanded from its downtown and Pattullo Ridge locations and now operates out of an 80,000 square foot facility. The company employs 44 people and has been unionized since 1953. It produces automotive and other metal parts using various presses and equipment and offers additional assembly and finishing services.