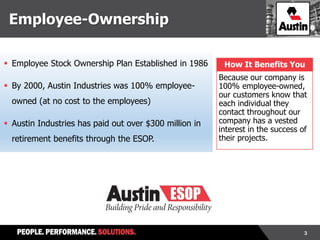

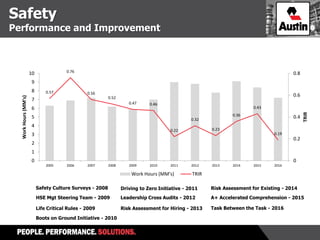

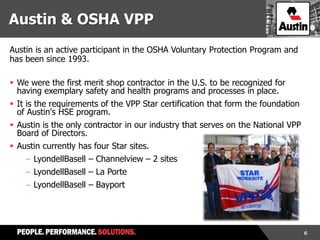

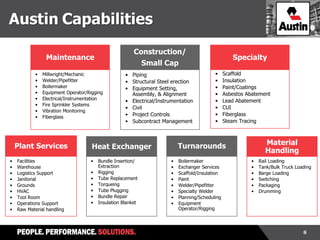

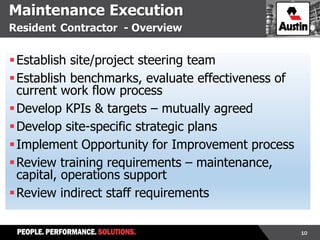

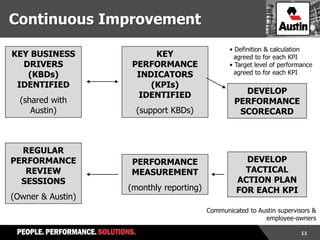

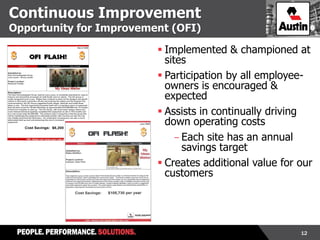

Austin Industries is a 100% employee-owned company founded in 1918 that provides construction, maintenance, and plant services. It has over 12,500 employee-owners across various US locations and annual sales of $2 billion. Austin has a diversified customer base in oil/gas, chemicals, energy, and other industries. It prides itself on its safety culture and employee ownership model.