Art jewelry corrugated_knot_chain_bracelet_howard_siegel

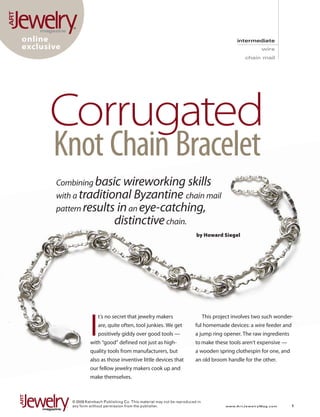

- 1. online intermediate exclusive wire chain mail Corrugated Knot Chain Bracelet Combining basic wireworking skills with a traditional Byzantine chain mail pattern results in an eye-catching, distinctive chain. by Howard Siegel I t’s no secret that jewelry makers This project involves two such wonder- are, quite often, tool junkies. We get ful homemade devices: a wire feeder and positively giddy over good tools — a jump ring opener. The raw ingredients with “good” defined not just as high- to make these tools aren’t expensive — quality tools from manufacturers, but a wooden spring clothespin for one, and also as those inventive little devices that an old broom handle for the other. our fellow jewelry makers cook up and make themselves. © 2009 Kalmbach Publishing Co. This material may not be reproduced in any form without permission from the publisher. www.A r t J e w e l r y M a g . c o m 1

- 2. Once you’ve made the tools, you can make this chain, which requires coiling, cutting, fusing, stretching, forging, annealing, and corrugating fine-silver wire, then connecting the corrugated rings with Byzantine knots made from handmade sterling silver jump rings. When you finish this eye-catching bracelet, you’ll have conquered a host of basic wireworking skills. make your own tools! materials ■ Fine-silver wire: 18-gauge (1.0 mm) Slotted screw round, 5 in. (12.7 cm) Rope recess (for flat head screwdriver) ■ Sterling silver wire: 20-gauge (0.8 mm), Drilled hole round, 4 ft. (1.2 m) ■ Sterling silver jump rings: 16-gauge (1.3 mm), 4 mm inside diameter, 2 Wire ■ Crab-claw clasp End of dowel/broom handle toolboxes, www.artjewelry mag.com/toolboxes ■ Chain mail • Clothespin tool (left): To make your own ■ Soldering jump rings, you’ll need to coil wire around a mandrel. You can do this by hand, but ■ Sawing/Piercing this handy tool, which you can make from ■ Wirework a spring-style wooden clothespin, helps control the tension of your wire as you coil it mechanically. additional tools & supplies ■ Wooden spring clothespin To make the clothespin tool, select a drill bit ■ Jump-ring-opening tool; or 3–4-in. that’s slightly larger than the gauge of wire you’ll use to make the jump rings. Insert this (76–102 mm) wooden dowel, bit into a flex shaft, and drill a 45° angle hole slotted screw (optional) through one leg of your clothespin, below ■ Coil winder the rope recess. The 45° angle will allow ■ V-block tool (optional) the wire to pass smoothly through the tool without kinking. ■ Shears ■ Tweezers • Jump ring opener (above): To help you use ■ Ring stretcher (or snap ring pliers) good technique while opening your jump (optional) rings, you can buy a slotted ring tool from ■ Felt-tip pen a tool manufacturer, but making your own is fairly simple. Start with a 3–4-in. (76–102 mm) ■ Corrugator (choose from): paper length of dowel (I used an old broom handle) crimper or tube wringer and screw a slotted screw into one end. suppliers ■ Mandrels, Blazer-type butane torch (Harbor Freight Tools, 800.444.3353, www.harborfreight.com) ACKNOWLEDGEMENTS The clothespin tool was shown to me by master chain maker Cao Madina. He has See Safety Basics at my thanks for sharing this very simple but useful tool. www.artjewelrymag.com/howto The idea for corrugating the links in this chain is the result of taking a corruga- tion workshop taught by Trish Macaleer for the Society for Midwest Metalsmiths. I was greatly aided in the composition and taking the chain process photo- graphs by Herb Halpern of Herb Halpern Productions. www.A r t J e w e l r y M a g . c o m 2

- 3. 1 2 3 Part 1: rings Make the jump easier to cut with a jeweler’s saw. You will need roughly 70 small jump rings to complete the bracelet. Position fine-silver wire in your Cut the sterling silver coils into jump clothespin tool. Cut a 31 ⁄2 -in. (89 mm) rings . Thread a 2/0 or 3/0 saw blade piece of fine-silver wire. Insert one end into one end of a jeweler’s saw . Thread of the wire through the drill hole in your clothespin tool (see “Make Your Own Tools!” page 2) so the wire comes out the blade through a sterling silver coil, then into the other end of the saw frame, and tighten. Lubricate the saw blade by 4 inside the rope recess. pulling the teeth through beeswax or Pull the wire through the hole and another lubricant. Continue cutting until it becomes the jaws of the clothespin until you have Place the coil against your bench pin. difficult. Then, collect the cut rings and a 1-in. (25.5 mm) tail. Use chainnose (Instead of using a bench pin, I use a V- resume cutting, taking care to align the pliers to make a 90° bend about ½–3 ⁄4 in. block tool that I designed and made for blades with the cut end of the last wrap (13–19 mm) from the end of the wire. myself [2].) Saw through the coil with the on the coil. Continue cutting the coil until saw blade tipped at roughly 45° so you’re you have cut all of the wraps. Prepare a coil winder. Insert a 9 mm only cutting through two or three wraps mandrel into a coil winder and tighten the at any time. Collect the jump rings as they Open the sterling silver jump rings. Pick chuck. Then insert the bent end of your separate from the coil, and resume sawing. up one sterling silver jump ring, and grip fine-silver wire into the jaws of the chuck, one side of the ring with chainnose pliers, tightening again if necessary. This will hold NOTE: Be careful to align the saw blade positioning the pliers’ tip close to the cut. the wire so you can wind the coil. with the cut end of the last ring. If not Place the other side of the jump ring in properly aligned, there will be two cuts the groove in your jump-ring-opening tool Wind the coils. Turn the coil winder’s in the ring, one only partially through the (see “Make Your Own Tools!” page 2; as an crank clockwise to wind the wire around ring. If you try to open a ring with a second alternative, you can use two pairs of pliers the mandrel. Use the clothespin tool to partial cut, the ring will break, making ) and twist the tool away from your guide the wire so the wraps lie side by side instant scrap metal. body until the ring is open about 60° [4]. with no gaps [1]. Continue until you have Repeat to open all the sterling silver wound all the wire; the coil should have Continue sawing until you’ve cut jump rings. about seven or eight wraps. Slide the coil all the wraps on the coil. Then, cut the off the mandrel. remaining sterling silver coils into Prepare the fine-silver jump rings for jump rings. fusing. Place a fusing or soldering board Coil the sterling silver wire. Using 8– on top of a firebrick to prevent burning 10 in. (20.3–25.4 cm) of sterling silver wire Cut the fine-silver coils into jump your bench. and a 3.6 mm mandrel, repeat the previous rings. Grasp the fine-silver coil in your Using pliers or your fingers, close a steps to make another coil. Wind a coil nondominant hand between the heel of fine-silver jump ring so that the cut edges about 2 in. (51 mm) long, then use flush your thumb and your fingers. Hold a pair make good contact. To do this, over-form cutters to cut the wire. Continue winding of shears in your dominant hand and the ring (bring the cut edges past each and cutting 2-in. (51 mm) coils until you insert the lower blade inside the coil [3]. other), then carefully pull them apart, and have coiled all the sterling silver wire. line up the cut edges. Make sure the edges NOTE: The shears should point down the are aligned both when viewed from the NOTE: Limiting the length of the sterling center of the length of the coil to ensure edge of the ring and down the center of coils to about 2 in. (51 mm) makes them that you don’t cut your hand. the ring. Place the closed ring on the www.A r t J e w e l r y M a g . c o m 3

- 4. 5 6 7 fusing board with the cut facing forward. will cause the join to “thin Repeat for the remaining fine-silver out,” then melt completely rings, placing them in a row across the and form a ball of metal on fusing board and leaving a little space either side of the join. If this between each ring. occurs, the ring is scrap. Try deliberately overheating the Fuse the fine-silver jump rings. Put on first ring so you can observe an Optivisor so you can clearly see the join in each ring as it fuses. what happens. Fuse all the fine-silver jump rings. 8 NOTE: If you hold your torch in your right You will need about eight fused rings to hand, start with the ring at the rear left of complete the bracelet. Use tweezers to rings. Forge all the fused jump rings in the the fusing board; if you hold your torch in push the fused rings off the fusing board same manner. your left hand, start at the rear right. This and into a water-filled container to cool. will minimize the danger of accidental Anneal the fine-silver rings. Forging burns by keeping your hand away from Stretch the fine-silver rings. Place the rings work-hardens the silver. Since previously fused rings. a fused ring on a ring stretcher about our next step will be to corrugate these halfway down the jaws [6]. (You could rings, we need to soften the metal. Move the torch flame in a circular also use roundnose pliers.) Mark this Annealing softens the metal and is motion around the first ring until it turns location on the stretcher with a felt-tip done by heating the metal . a dull red. (I use a propane-fueled pencil pen so you can position all the rings in Place the forged rings in a row on the torch, but any standard jeweler’s torch the same place and stretch them to the fusing board and turn down the lights. setup will work, including a handheld same size. Heat each ring until it is dull red, then butane model.) move on to the next, keeping the torch NOTE: Position the fused join on the moving in a circular motion so you don’t TIP: When you’re fusing, turn outside of one jaw of the stretcher. This melt the rings. After heating all the rings, down your studio lights to will stretch the ring so that the join will push them into the container of water to make it easier to see the be inside the chain and not visible on the cool them. metal change color as you finished bracelet. heat it. Corrugate the fine-silver rings. Use Stretch all the fine-silver rings. chainnose pliers to place the narrow end Once you see the color change, move of a forged and annealed ring into the the flame to the join in the ring and move Forge the fine-silver rings. Place a corrugator. I used a paper crimper from the flame in a small circle. Concentrate the stretched ring over the corner of a bench a local craft store as a corrugator; you heat evenly on both sides of the join [5]. block so that only half of the ring is on the could also use a tube wringer. Whichever In a short time, the silver at the join block [7]. style of tool you choose, use it according will melt and surface tension will pull the Use the flat face of a ball-peen hammer to the manufacturer’s instructions to molten metal together, fusing the join to flatten this side of the ring to about corrugate the ring [8]. Corrugate all the without the use of solder. twice its initial width. Reposition the ring fine-silver rings. so that the other side of the ring is across TIP: When you’re fusing the corner of the bench block, and flatten jump rings, remove the flame this side. from the join as soon as the Try to forge both legs to the same metal melts. Overheating width. Do not forge the curved ends of the www.A r t J e w e l r y M a g . c o m 4

- 5. Process photos by Herb Halpern. 1 2 3 Part 2: bracelet Assemble the Byzantine knots until your chain reaches the desired length. End the chain with a Byzantine knot (rather than a single ring). Bonus Videos Check out these bonus tutorials for fundamental techniques used in this project: Weave the chain. Pick up a corrugated Add the clasp and finish the chain. ring. (If desired, you can thread a paper Open two 4 mm inside diameter (ID) ■ Making jump rings clip or twist tie through this ring for a sterling silver jump rings. Thread a single ■ Threading a saw blade better grip.) Thread a 3.6 mm sterling silver 4 mm jump ring through the Byzantine in a saw frame ■ Opening and closing jump rings jump ring through the corrugated ring and knot at the end of the chain; add the clasp ■ Annealing metal close it; repeat with a second 3.6 mm ring. to this jump ring and then close the ring. Thread a third 3.6 mm ring through the Thread a second 4 mm jump ring first pair of rings and close it; repeat to through the corrugated ring at the end Videos, www.artjewelrymag. add a fourth 3.6 mm ring [1]. of the chain, then close the ring. This com/howto Grasp the corrugated ring and the first ring will form the other half of the clasp. pair of 3.6 mm rings between your thumb Alternately, you can skip this second jump and forefinger. Separate the second pair of ring and close the bracelet by closing the 3.6 mm rings and flip them back, one to clasp through the final elongated corru- each side of the first pair [2]. gated link. Howard Siegel Grasp the corrugated ring and the Place the chain in a tumbler with has a master’s second pair of 3.6 mm rings between your mixed stainless steel shot and burnishing degree in metal- thumb and forefinger, and push up on compound. Tumble the chain for 1–2 lurgy and works the second pair of rings. Insert a scribe or hours. Remove the chain from the tumbler, in lapidary, needle tool above the corrugated ring rinse it with running water, and then dry silversmithing, to hold the first pair of rings open and it. Pull the chain through your hand. If and chain expose the second pair of rings [3]. the chain feels rough, put it back in the making. He Thread a fifth 3.6 mm ring through tumbler, and tumble it until the chain feels teaches at the William Holland School the V-shaped opening in the knot, then smooth. Additional tumbling will not harm of Lapidary Arts, the Society for Mid- through a second corrugated ring, and the chain. west Metalsmiths, the Craft Alliance, close it. Repeat to add a second 3.6 mm and the Jacoby Arts Center. ring through the same path, going through the two 3.6 mm rings and the corrugated ring. You have just completed a Byzantine knot at the end of the first corrugated ring and added a second corrugated ring to your chain. Each corrugated ring and Byzantine knot is slightly under 1 in. (25.5 mm) long; you can estimate the length of the chain by counting the corrugated rings. Continue adding corrugated rings and www.A r t J e w e l r y M a g . c o m 5

- 6. Make it No matter what kind of jewelry you’d like to make — or what technique you’d like to master — you’ll get all the inspiration and advice you need from leading jewelry artisans in every issue of Art Jewelry magazine. Plus, subscribers gain exclusive online access! Post photos of your work in the Subscriber Gallery, read reviews of products tested by the editors, and download free projects. Art Jewelry covers: ■ Metals ■ Chain mail ■ Metal clay ■ Polymer clay ■ Stones and gems ■ Enamel ■ Wire ■ And more! Subscribe today to learn new techniques! Order online at www.ArtJewelryMag.com/promo Enter promotional code: IK87Z Or call 1-800-533-6644 Monday – Friday, 8:30 a.m. –5:00 p.m. Central Time. Outside the U.S. and Canada, call 262-796-8776, ext. 661. CIR-ADH-08X1876RH