This document provides an overview and table of contents for a textbook on embedded systems using ARM architecture. It discusses how 32-bit systems like those based on ARM are becoming the mainstream for embedded systems due to their improved processing capabilities over 8-bit and 16-bit systems. It also notes that existing books on ARM focus on chip design, applications, or development boards rather than application development suitable for undergraduate teaching, which is the purpose of this textbook. The table of contents outlines chapters on embedded systems, embedded systems engineering, and the ARM7 architecture.

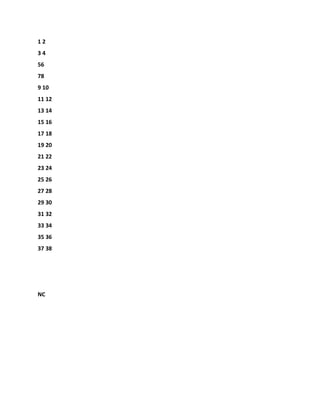

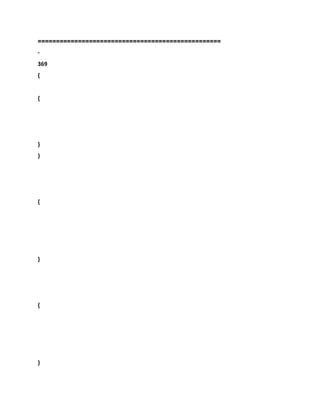

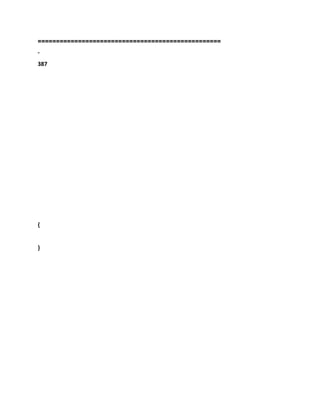

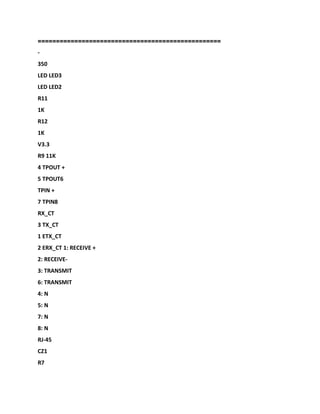

![==================================================

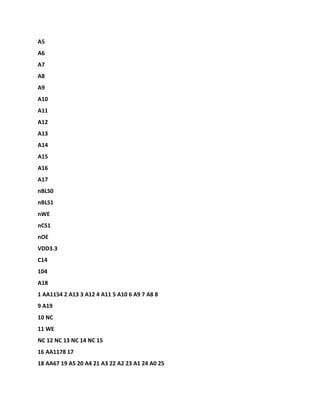

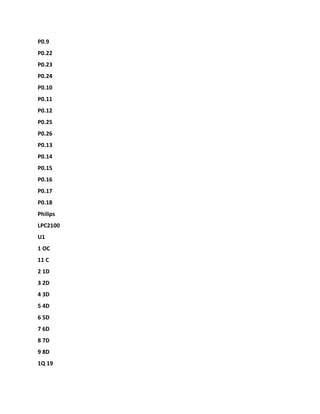

-

30

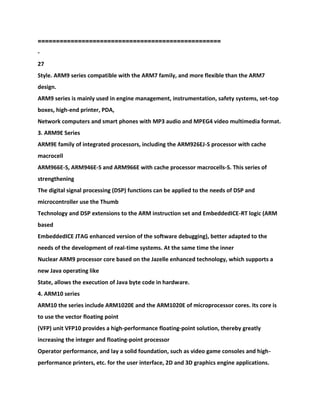

32 - bit ALU

CLK

CLKEN

CFGBIGEND

nFIQ

nRESET

ABORT

TRANS [1:0]

PROT [1:0]

SIZE [1:0]

WRITE

LOCK

WDATA [31:0] RDATA [31:0]

ADDR [31:0]

Address register

Scan debug

Control

Write data register

CP handshake

CP control

DBG input

DBG output

Instruction decoder

And

Control logic

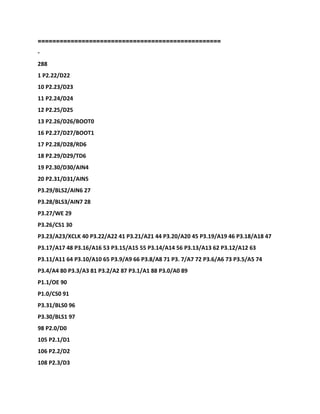

Register set](https://image.slidesharecdn.com/armembeddedsystemessentialszlg-230111081204-4bc9ad56/85/ARM-Embedded-System-Essentials-ZLG-docx-106-320.jpg)

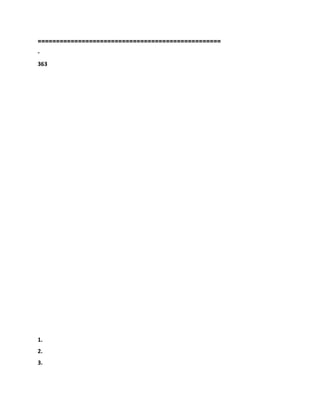

![31 × 32 - bit register

(6 Status Register)

Address the increase

Barrel shifter

The instruction pipeline read data register

Thumb instruction decoder

Multiplier

nIRQ

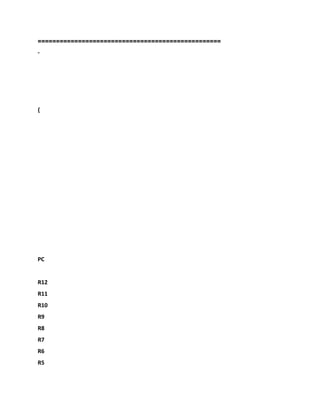

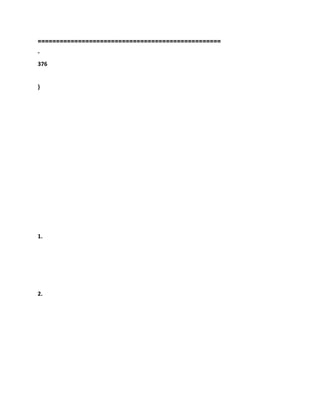

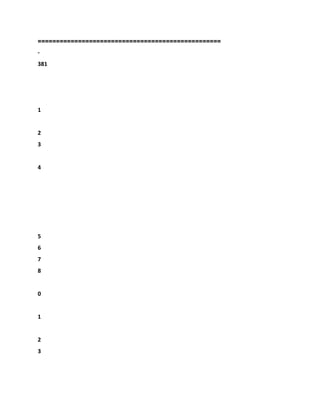

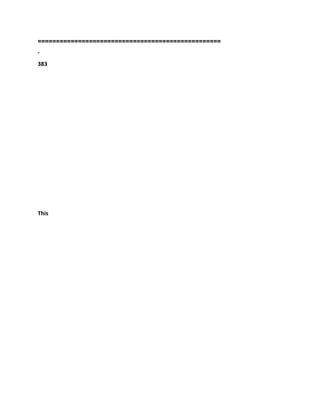

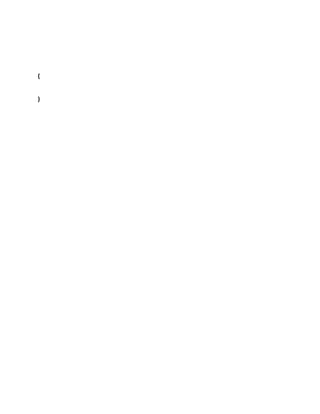

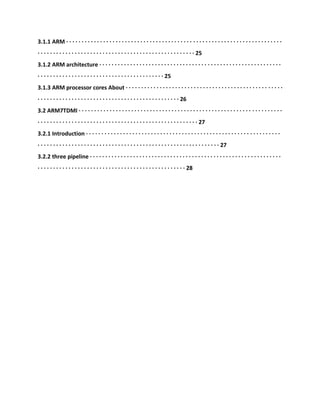

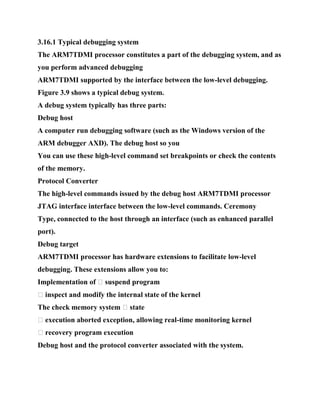

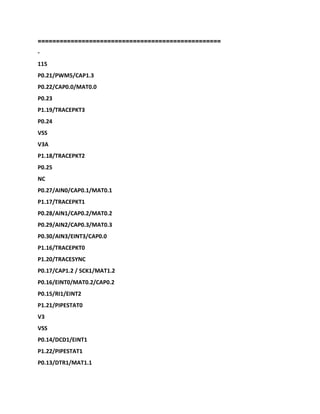

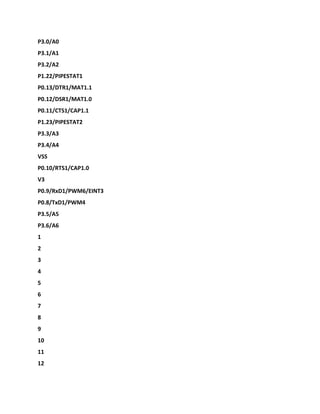

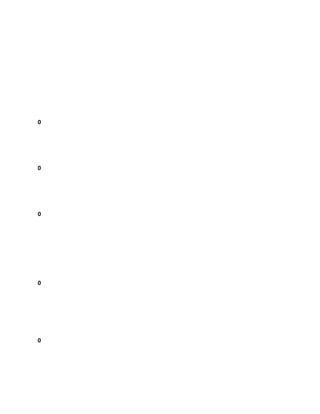

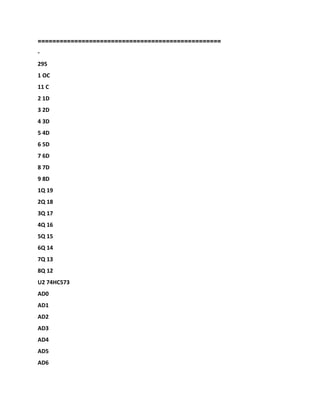

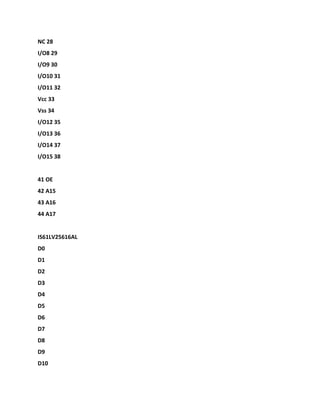

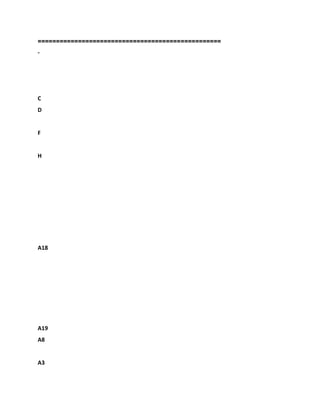

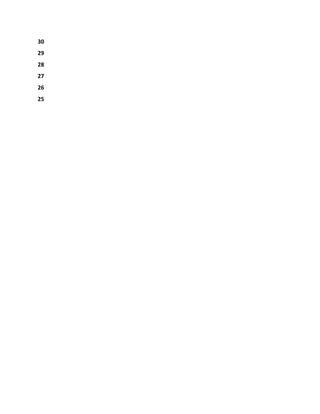

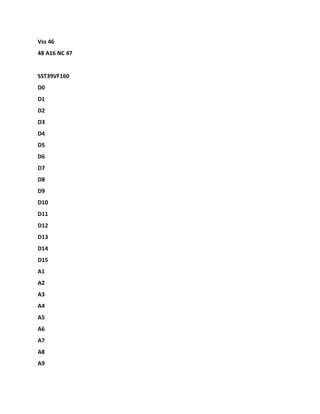

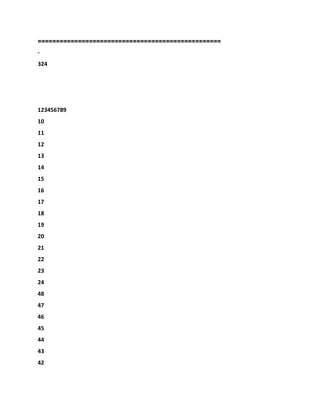

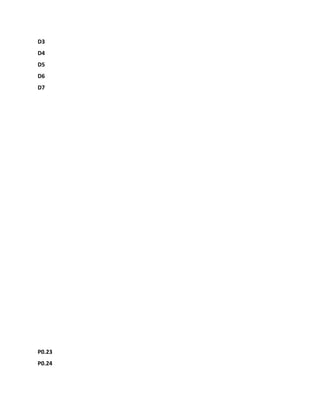

Figure 3.3 ARM7TDMI kernel

===========================================================

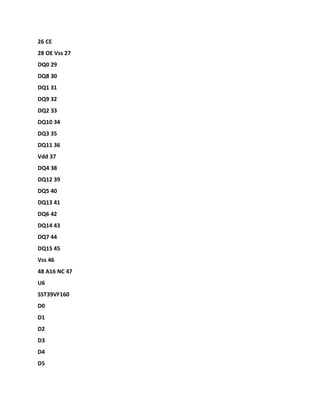

-

31

CPB

CPA

CPnI

CPTBIT

CPSEQ

CPnMREQ

CPnOPC

CPnTRANS

TRANS [1:0]

PROT [1:0]

SIZE [1:0]

WRITE

ABORT

RDATA [31:0]

WDATA [31:0]

ADDR [31:0]

DBGTDO](https://image.slidesharecdn.com/armembeddedsystemessentialszlg-230111081204-4bc9ad56/85/ARM-Embedded-System-Essentials-ZLG-docx-107-320.jpg)

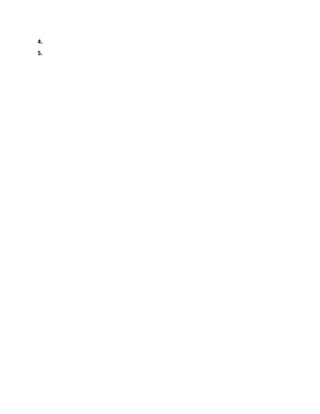

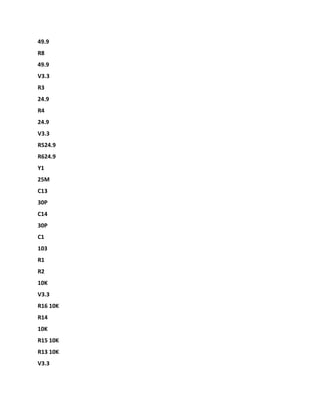

![DBGnTDOEN

DBGnTRST

DBGTDI

DBGTMS

DBGTCKEN

DBGCOMMTX

DBGCOMMRX

DBGRNG [0]

DBGRNG [1]

DBGEN

DBGEXT [0]

DBGEXT [1]

DBGnEXEC

DBGACK

DBGBREAK

DBGRQ

LOCK

CFGBIGEND

nRESET

nFIQ

nIRQ

CLKEN

CLK

DBGINSTRVALID

DMORE ARM7TDMI-S

Synchronization

EmbededICE-RT

Scan Debug Access Port

Memory interface](https://image.slidesharecdn.com/armembeddedsystemessentialszlg-230111081204-4bc9ad56/85/ARM-Embedded-System-Essentials-ZLG-docx-108-320.jpg)

![-

34

Assembler program in ADS1.2 directly support these names, but pay attention to the a1-a4,

v1 to v8 must use the lowercase letters. Details, see Reference [1].

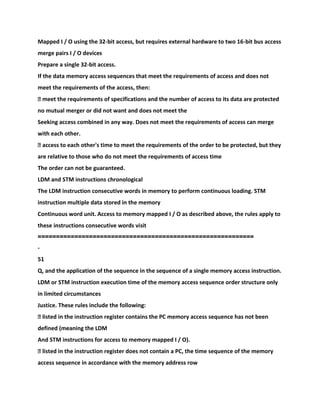

(2) Average of general purpose registers

In assembly language register R0 ~ R13 to save data or address values of the general-purpose

registers. Which registers R0 ~ R7

The ungrouped register. This means that for any processor mode, each of them

corresponding to the same 32-bit

Physical register. They are completely general purpose register is not architecture as a special

purpose, and may be used for any

Using the general purpose registers of the instruction.

Register R8 ~ R14 group register. Their corresponding physical register depends on the

current processor mode. A few

Almost all instruction allows the use of general-purpose registers allows the use of packet

register.

Registers R8 ~ R12 have the physical registers of the two packets. One for outside the FIQ

mode registers mode

(R8 to R12), the other for the FIQ mode (R8_fiq ~ R12_fiq).

Register R8 ~ R12 ARM architecture without a specific purpose. But for those who use only R8

~ R14

These registers are sufficient to handle simple interrupt FIQ used alone can achieve the fast

interrupt processing.

The registers R13 and R14, respectively, the physical registers of the six packets. One for the

user and system mode, the remaining five

And one each for the five kinds of abnormal patterns.

(3) the stack pointer R13

The registers R13 usually as the stack pointer (SP). ARM instruction set, which the use is not

in a special way.](https://image.slidesharecdn.com/armembeddedsystemessentialszlg-230111081204-4bc9ad56/85/ARM-Embedded-System-Essentials-ZLG-docx-114-320.jpg)

![Read general limitations of the program counter

Read the instructions on the R15 to read no more than any restrictions on the R15, the value

is the address of the instruction plus

8 bytes. Units, the results of the bit ARM instructions are always word [1:0] is always 0.

Read the PC is mainly used on the the nearby instructions and data quickly, and location-

independent addressing

The program has nothing to do with the location of the transfer.

When using STR or STM instructions save R15, an exception to the above rule. These

instructions can be the finger

Address plus 8 bytes saved (and other instructions to read R15) or the instruction plus 12

bytes (the future can also own address

Appearing on other data). Offset 8 or 12 (or other value) depends on ARM implementations

(ie,

Chip-related). For a specific chip, it is a constant. STR and STM instructions are not so

portable.

Since this exception, it is best to avoid using the STR and STM instructions to save R15. If it is

difficult to do, then should

Suitable instruction sequence offset used to determine the current use of the chip used in the

program. For example, using the program list

The the 3.2 instruction sequence shown in this offset stored in R0.

Program Listing 3.2 offset concrete chip storage PC

SUB R1, PC, # 4; R1 = following STR instruction address

STR PC, [R0]; Save the the STR instruction address + offset

LDR R0, [R0]; then reinstall

SUB R0, R0, R1; offset

General limit to write the program counter

R15 instruction does not exceed any limit its use when executing a write, write R15 normal

results

Value as an address of the instruction, the program from this address to continue (equivalent](https://image.slidesharecdn.com/armembeddedsystemessentialszlg-230111081204-4bc9ad56/85/ARM-Embedded-System-Essentials-ZLG-docx-117-320.jpg)

![to perform an unconditional jump).

ARM instruction word boundary, so write the value of R15 bit [1:] usually 0b00. The specific

rules depends

The used version of the structure:

� V3 version and the following versions of the ARM architecture, write the value of R15 bit

[1:0] are ignored, so the instruction real

The International destination address (the value written to R15) and 0xFFFFFFFC phase.

� structure V4 version in ARM (ARM7TDMI based on the V4 version) and above, write the

value of R15 bit [1:0]

Must be 0b00. If not, the results will be unpredictable.

(6) The program status register

All modes share a program status register (CPSR), abnormal pattern, a register program

status

Save register (SPSR) can be accessed. Each exception has its own SPSR, save it into the

abnormal CPSR

The current value of it to restore the CPSR abnormal exit. The description of the program

status register, see 3.8.

3.7.3 Thumb state register set

(1) each of the modes can be accessed register

Thumb state register set is a subset of the ARM state set. Programmers can directly access:

� 8 general purpose registers R0 to R7

===========================================================

-

36

� PC

� stack pointer (SP)

� connection Register (LR)

� CPSR (conditional access)

SP and LR for each privileged mode packet. Thumb registers detailed in Table 3.3.](https://image.slidesharecdn.com/armembeddedsystemessentialszlg-230111081204-4bc9ad56/85/ARM-Embedded-System-Essentials-ZLG-docx-118-320.jpg)

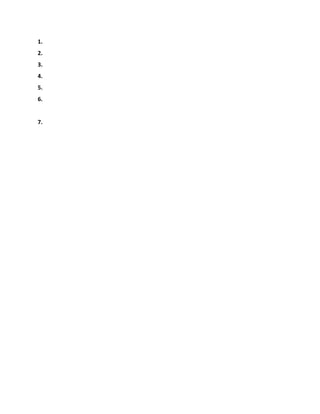

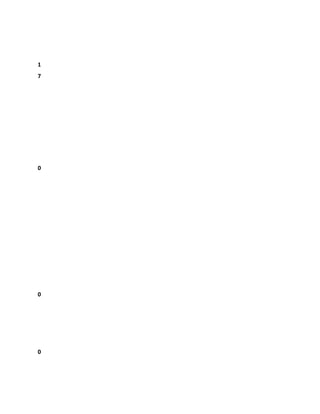

![Table 3.3 Thumb state mode register

Register each mode access register

Category

Register in assembly

In the name of the user system management abort undefined interrupt fast interrupt

R0 (a1) R0

R1 (a2) R1

R2 (a3) R2

R3 (a4) R3

R4 (v1) R4

R5 (v2) R5

R6 (v3) R6

R7 (v4, WR) R7

SP R13 R13_svc R13_abt R13_und R13_irq R13_fiq

LR R14 R14_svc R14_abt R14_und R14_irq R14_fiq

General-purpose registers and program counter

PC R15

Status register

Register

CPSR CPSR

Note: brackets ATPCS register naming RN assembler directive to register multiple names, you

can use. Among them,

Assembler ADS1.2 the direct support for these names, but note a1-a4 v1 ~~ v4 must be in

lowercase. Details, refer to Reference [1].

(2) Average of general purpose registers

Register R0 ~ R7 to save data or address values of the general-purpose registers in assembly

language. For any processor module

Formula, each of them corresponding to the same 32-bit physical registers. They are

completely general-purpose registers, will not be](https://image.slidesharecdn.com/armembeddedsystemessentialszlg-230111081204-4bc9ad56/85/ARM-Embedded-System-Essentials-ZLG-docx-119-320.jpg)

![Interrupt Disable bit

I and F bits are the interrupt disable bits:

� When I bit is set, IRQ interrupts are disabled

� when the F bit, FIQ interrupts are disabled

===========================================================

-

39

T bit

T bit reflects the state are operating:

� when the T bit, the processor is in Thumb state run

� when the T bit is cleared, the processor is ARM state run

Warning: Do not force changes in the T bit in the CPSR register. If you do this, the processor

will enter an inability

Unknown state.

Mode bit

M4, M3, M2, M1 and M0 bits (M [4:0]) are the mode bits. These bits determine the

processor's operating mode, see Table

3.4. Not all of the combinations of the mode bits define a valid processor mode, so be careful

not to use the table does not

The combinations listed.

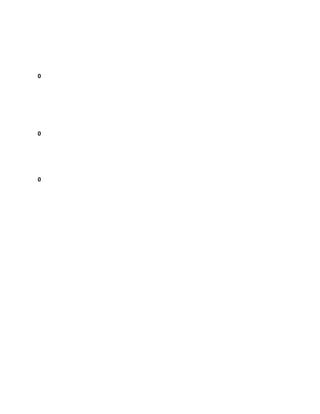

Table 3.4 CPSR mode bits value

M [4:0] the pattern visible Thumb state registers visible ARM state register

The 10,000 users R0 to R7, SP, LR, PC, CPSR R0 to R14, the PC, CPSR

10001 fast interrupt R0 ~ R7, SP_fiq, LR_fiq, PC, CPSR,

SPSR_fiq

R0 ~ R7, R8_fiq ~ R14_fiq, PC, CPSR,

SPSR_fiq

10010 interrupt R0 ~ R7, SP_irq, LR_irq, PC, CPSR,

SPSR_fiq](https://image.slidesharecdn.com/armembeddedsystemessentialszlg-230111081204-4bc9ad56/85/ARM-Embedded-System-Essentials-ZLG-docx-125-320.jpg)

![R0 ~ R12, R13_irq, R14_irq, PC, CPSR,

SPSR_irq

10011 management R0 ~ R7, SP_svc, LR_svc, PC, CPSR,

SPSR_svc

R0 ~ R12, R13_svc, R14_svc, PC, CPSR,

SPSR_svc

10111 abort R0 ~ R7, SP_abt, LR_abt, PC, CPSR,

SPSR_abt

R0 ~ R12, R13_abt, R14_abt, PC, CPSR,

SPSR_abt

11011 undefined R0 to R7, SP_und LR_und, PC, CPSR,

SPSR_und

R0 ~ R12, R13_und, R14_und, PC, CPSR,

SPSR_und

11111 system R0 to R7, SP, LR, PC, CPSR R0 to R14, the PC, CPSR

Note: If you write illegal values M [4:0], the processor will enter an unrecoverable mode.

3.8.4 reserved bits

Reserved bits in the CPSR are reserved for future use. Make sure when to change the the

CPSR flag and control bits when not changed

These reserved bits. Also, make sure your program does not rely on reserved bits containing

specific values, because the future of the processor may

These bits are set to 1 or 0.

3.9 abnormal

3.9.1 Introduction

Normal program flow is temporarily suspended, the processor enters exception mode. For

example, in response to an interrupt from a peripheral.

Before handling exceptions, ARM7TDMI core save the current state of the processor, so that

when the end of the handler can recover

Repeatedly executed the original program.](https://image.slidesharecdn.com/armembeddedsystemessentialszlg-230111081204-4bc9ad56/85/ARM-Embedded-System-Essentials-ZLG-docx-126-320.jpg)

![Note: ARM7TDMI processor completely follow ARM architecture v4T, you can capture all

Category undefined instruction bits

Format.

Instructions to prevent failure, capture the processor to execute the following command:

MOVS PC, R14_und (ie undefined mode execution MOVS PC, R14 instruction)

This action to restore the PC and CPSR, and returns to the instruction after the undefined

instruction.

The undefined instruction more detailed information please refer to reference [2].

3.9.10 exception vector

Table 3.6 shows the exception vector address. , I, and F represents the previous value in the

table.

Table 3.6 exception vector

Address abnormal entry mode to enter when I state into the state of the F

0x00000000 reset management are prohibited

0x00000004 undefined instruction is undefined I F

0x00000008 software interrupt management prohibited F

=================

==========================================

-

43

Connected to the table

Address abnormal entry mode to enter when I state into the state of the F

And 0x0000000C abort abort (prefetch) I F

0x00000010 abort abort (data) I F

0x00000014 Reserved -

0x00000018 IRQ interrupts disabled F

The 0x0000001C FIQ fast interrupt prohibited prohibition

3.9.11 Exception Priorities

When multiple exceptions occur simultaneously, a fixed priority system determines the order

in which they are processed:](https://image.slidesharecdn.com/armembeddedsystemessentialszlg-230111081204-4bc9ad56/85/ARM-Embedded-System-Essentials-ZLG-docx-133-320.jpg)

![Zero Wait.

� Texc, data abort the time of the entrance. Texc for three cycles (determined by the kernel).

� Tfiq the FIQ entrance time. Tfiq for two cycles (determined by the kernel).

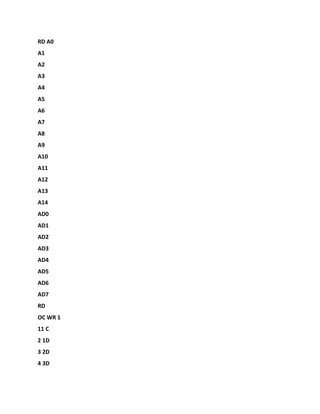

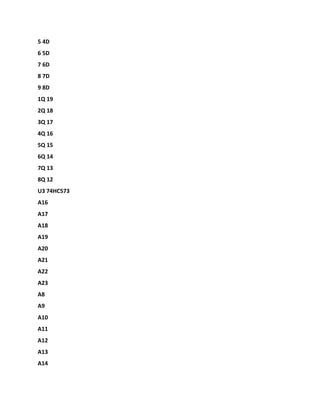

Therefore, the total delay time for the 27 cycles, the system uses a 40 MHz processor clock,

slightly less than 0.7 microseconds.

Located 0x1c at the instruction after the end of this time, ARM7TDMI execution.

Largest IRQ delay time is similar, but must take into consideration such a fact, i.e. a higher

priority FIQ

When the application of the FIQ and IRQ, IRQ delay to FIQ handlers to allow the IRQ interrupt

when handling (you may need

Corresponding interrupt controller). IRQ delay time should be correspondingly increased.

======================================

=====================

-

44

3.10.2 Minimum interrupt latency

FIQ or IRQ minimum interrupt latency request through the the time synchronizer plus

Tsyncmin Tfiq (4 processing

Control cycle).

3.11 Reset

Other sources of reset when nRESET signal is pulled low (usually external reset pin level

changes and chip change

Core signal), the ARM7TDMI processor abandon the instruction being executed.

NRESET signal goes high again, ARM processor performs the following actions:

Forced M [4:0] becomes b10011 (management model)

Set CPSR I and F bits

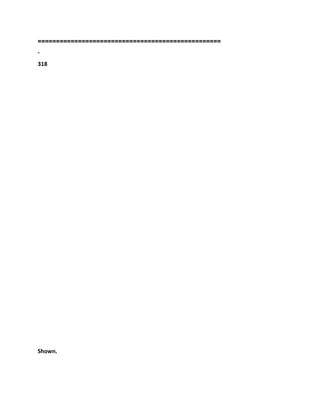

3. Clears the T bit in the CPSR

4. Force the PC began to fetch the next instruction from address 0x00.

5. Return to ARM state and resume execution

After reset, all register values except the PC and CPSR are not OK.](https://image.slidesharecdn.com/armembeddedsystemessentialszlg-230111081204-4bc9ad56/85/ARM-Embedded-System-Essentials-ZLG-docx-135-320.jpg)

![Note: The load and save memory format of the rules means that the word is not influenced

by the size of the end of the configuration. Therefore, not

Can save a word to change the memory format, and then reload the saved words so that the

order of the bytes of the word among the flip.

In general, change the the ARM processor configuration memory format memory system

does not make it different from the connection

What is the use of an additional structure defined operation, because to do so results and will

not produce. Therefore typically only in the reset

Change the configuration of the memory format so that it matches the memory system

memory format.

3.12.4 unaligned memory access

ARM the structure normally expect all memory accesses are reasonable alignment.

Specifically word accesses address usually

Word aligned halfword access address halfword aligned. Not memory access is called the

non-aligned in this manner

Aligned memory access.

Non-aligned instruction fetch

If the ARM state will be a non-word aligned address to write R15, the result is usually

unpredictable. If the Thumb

State to a non-aligned halfword address written to R15, address bits bit [0] is usually ignored

(see 3.7 and Chapter 4 each

A detailed description of the specific instruction). Results valid code from R15 in ARM state

read out the value of bit [1:0] 0 in

Bit0 of the Thumb state readout R15 value is 0.

When the the provisions ignore these bit, ARM implementation does not require instruction

fetch bit is cleared. Can be written to R15

The value of the change is sent to the memory, ARM or Thumb instruction fetch request

address bits are ignored bit [1:0]

Or bit [0].](https://image.slidesharecdn.com/armembeddedsystemessentialszlg-230111081204-4bc9ad56/85/ARM-Embedded-System-Essentials-ZLG-docx-141-320.jpg)

![Unaligned data access

Action one unaligned access load / save instructions will appear the following definitions:

� unpredictable

� access is not aligned low address bits are ignored. This means that when the half-word

access using Equation (ADDRESS AND

0xFFFFFFFE), and when the word access to use formula (address AND 0xFFFFFFFC).

� access is not aligned low address bits are ignored memory access control devices, and then

use these low address bits

The upload data cycle (the action is only applicable to LDR and SWP instruction).

Which of the three options suitable for load / save instruction depends on the instruction

(see Chapter 4).

===========================================================

-

47

Be sent to the address memory the ARM requirements will result in non-aligned low address

bits are cleared. Can be installed

Load / save instruction calculates an address does not change, is sent to the memory, and the

half-word access or word access request memory

The system ignores address bit bit [0] or bit [1:0].

3.12.5 prefetch instruction and self-modifying code

Many ARM to achieve the first execution of an instruction has not yet completed the

instruction fetched from memory. This action is called

Instruction prefetch. Instruction prefetch not actual execution instruction. Instruction did not

subsequently perform two typical situation:

� When an exception occurs, the current instruction is finished, all prefetch instructions are

discarded, execution of instructions from abnormal

Vector begins.

� When the jump occurred, the prefetched instruction after the branch instruction will be

discarded.](https://image.slidesharecdn.com/armembeddedsystemessentialszlg-230111081204-4bc9ad56/85/ARM-Embedded-System-Essentials-ZLG-docx-142-320.jpg)

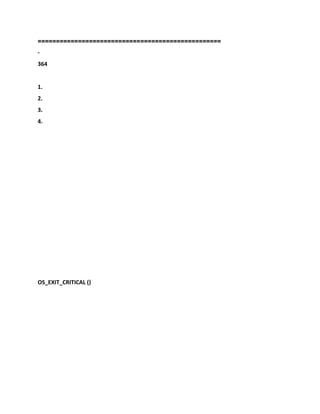

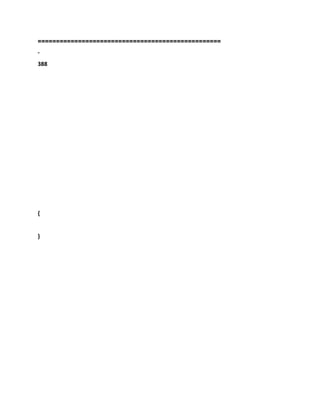

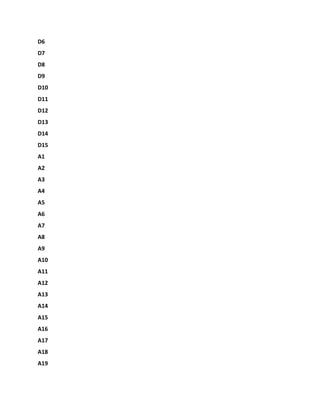

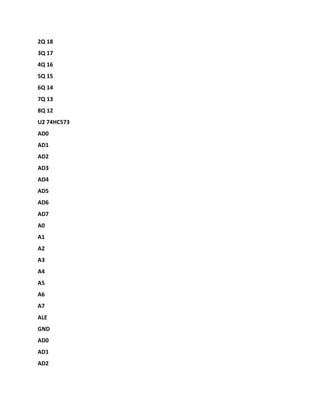

![EmbeddedICE-RT

DBGRNG [1:0]

DBGACK

DBGBREAK

DBGCOMMTX

DBGCOMMRX

DBGRQ

DBGEXT [1:0]

DBGEN

TAP

DBGTCKEN

DBGTMS

DBGTDI

DBGTDO

DBG nT RT S

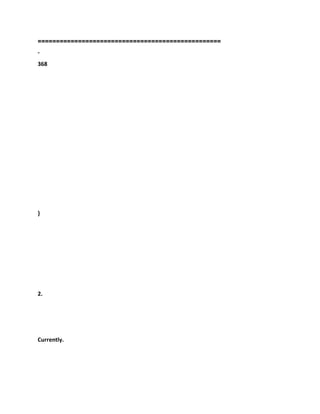

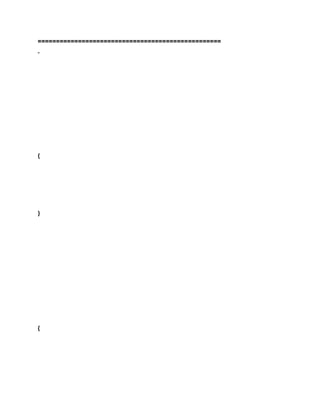

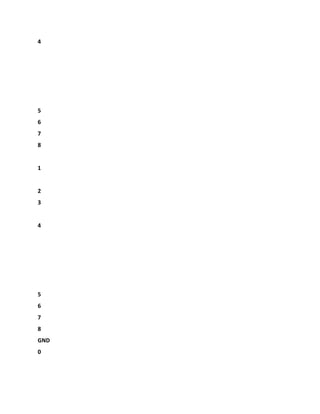

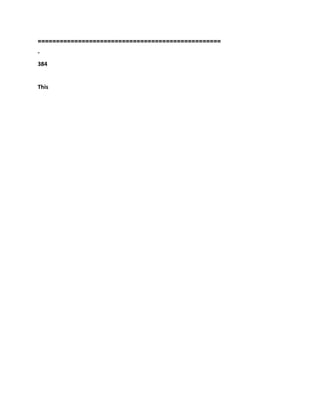

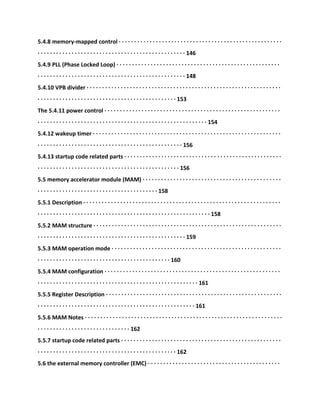

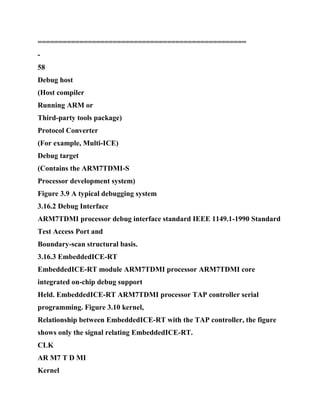

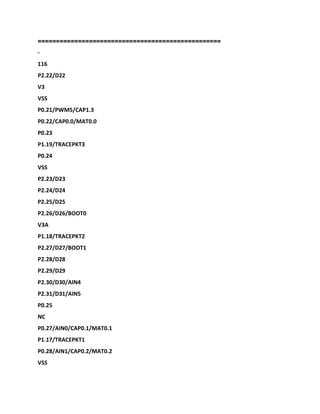

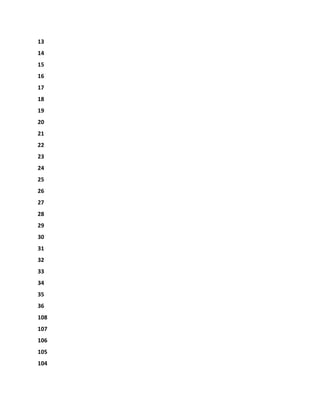

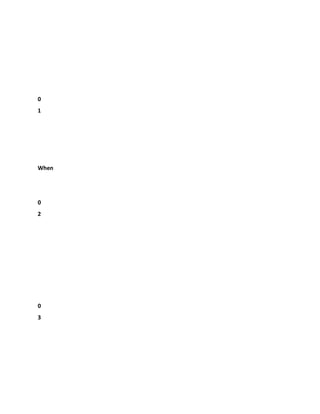

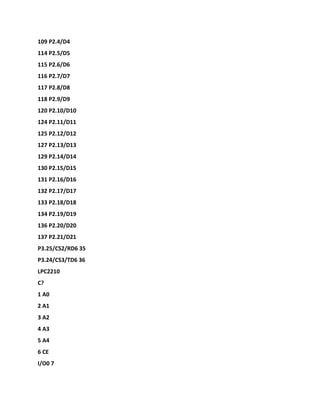

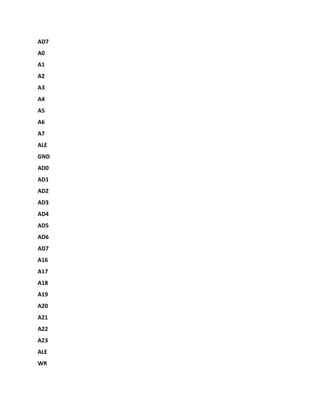

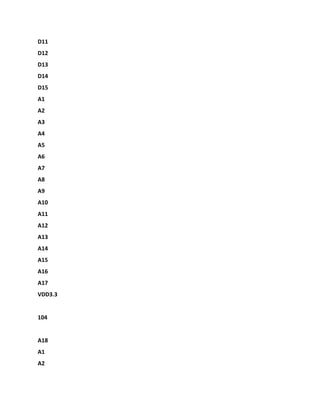

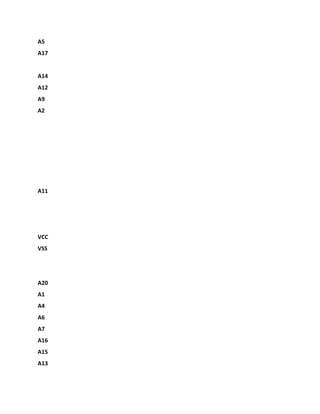

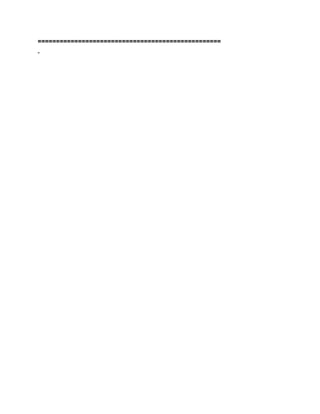

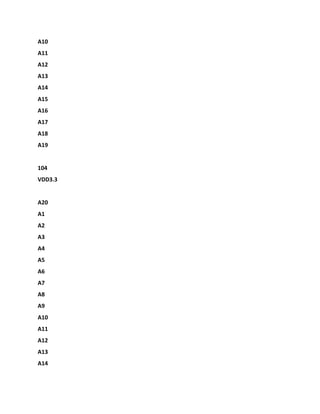

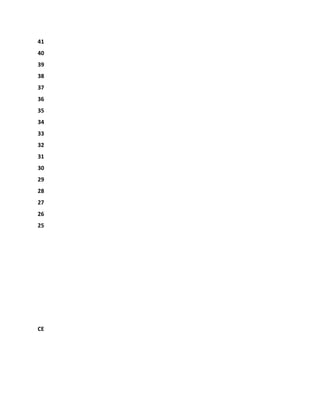

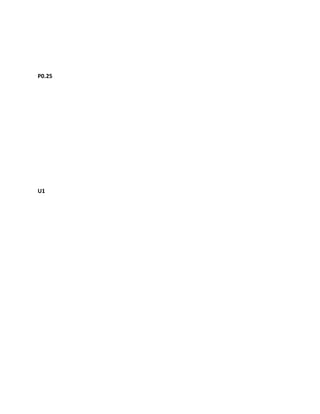

Figure 3.10 ARM7TDMI core TAP controller and the EmbeddedICE-RT

macrocell](https://image.slidesharecdn.com/armembeddedsystemessentialszlg-230111081204-4bc9ad56/85/ARM-Embedded-System-Essentials-ZLG-docx-175-320.jpg)

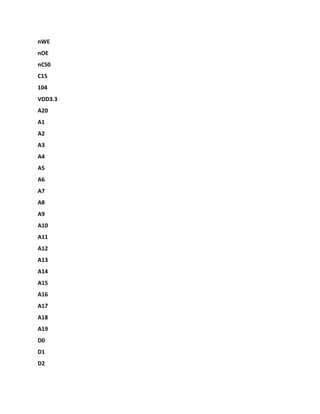

![==================================================

-

62

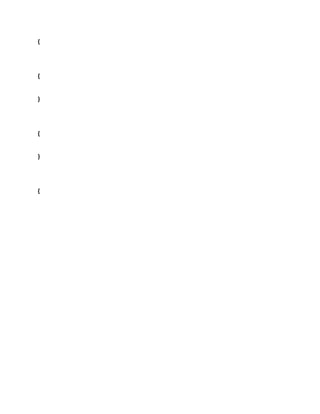

The various shift operation is shown in Figure 4.1.

(A) LSL shift operation

(B) LSR shift operation

(C) ASR shift operation

(D) ROR shift operation

(E) RRX shift operation

Figure 4.1 shift operation schematic diagram

Register indirect addressing

Address register indirect addressing instruction code given a number of

general-purpose registers, and the number of operations required to save in

Register specifies the address of the storage unit, i.e., the register is the

address of the operand pointer. For example, register indirect addressing

instruction

Follows:

LDR R1, [R2]; R2 pointing to a memory cell data is read out, stored in the R1

SWP R1, R1, [R2]; the exchange of the value of the register R1, and R2

specify the contents of the storage unit

5 Based addressing

Based addressing is the sum of the contents of the base register and

instruction given offset formed operand effective

Address. Based addressing is used to access near the base address of the

storage unit, commonly used in the look-up table, an array of operating

features register access

And so on. Based addressing instruction for example as follows:](https://image.slidesharecdn.com/armembeddedsystemessentialszlg-230111081204-4bc9ad56/85/ARM-Embedded-System-Essentials-ZLG-docx-183-320.jpg)

![LDR R2, [R3, # 0x0C]; read R3 +0 x0C address the contents of the storage

unit, into the R2

STR R1, [R0, # -4]!; First R0 = R0-4, then the value of R1 Storage to save

specified to R0

; Storage unit

LDR R1, [R0, R3, LSL # 1]; readout R0 + R3 × 2 address the contents of the

storage unit, memory

; Into R1

Register addressing

Multi-register addressing that one can send several register values, allow an

instruction to send the 16 registers any child

Set or register. Examples of multi-register addressing instruction as follows:

LDMIA R1!, {R2-R7, R12}; the R1 point unit data read out to R2 ~~ R7, R12

; (R1 automatically incremented by 1)

STMIA R0!, {R2-R7, R12}; register R2 ~ R7, R12 value of saved storage

pointed to R0

; Unit (R0 automatically incremented by 1)

0

0

C](https://image.slidesharecdn.com/armembeddedsystemessentialszlg-230111081204-4bc9ad56/85/ARM-Embedded-System-Essentials-ZLG-docx-184-320.jpg)

![===================================================

-

65

Must be written {<cond>} instruction execution condition is optional. If writing

is to use the default condition AL (unconditional

Execution).

opcode instruction mnemonic, LDR, STR.

cond execution condition, such as EQ, NE.

S would not affect the value of the CPSR, writing affect the CPSR.

Rd target register.

Rn an operand register.

operand2 two operands.

The instruction format for example as follows:

LDR R0, [R1]; read the R1 address of the memory cell content, the execution

condition Al

The BEQ DATAEVEN; branch instruction execution condition EQ, ie equal, jump

; To DATAEVEN

ADDS R1, R1, # 1; addition instruction, R1 +1 => R1, affect the CPSR (S)

SUBNES R1, R1, # 0x10; conditional execution subtraction operation (NE), R1-

0x10 => R1, impact

; CPSR register (S)

The first two operands

ARM instruction, the flexibility to use two operands to improve code efficiency.

Two operand forms such as

Follows:](https://image.slidesharecdn.com/armembeddedsystemessentialszlg-230111081204-4bc9ad56/85/ARM-Embedded-System-Essentials-ZLG-docx-192-320.jpg)

![� # immed_8r - constant expression

The constant must correspond to 8-bit bitmap (pattern), that the constant is

shifted by an 8-bit constant cycle even bits obtained.

Legitimate constants: 0x3FC (0xFF << 2), 0, 0xF0000000 (0xF0 << 24), 200 (0xC8),

0xF0000001 (0x1F << 28).

Illegal constant: 0x1FE 511,0 xFFFF, 0x1010, 0xF0000010.

The constant expressions application example:

MOV R0, # 1; R0 = 1

AND R1, R2, # 0x0F; R2 and 0x0F save the result in R1

LDR R0, [R1], # -4; read the R1 address the memory unit contents, and R1 = R1-4

� Rm - register way

In the mode register, the operand is the register values.

The register mode application example:

SUB R1, R1, R2; R1-R2 => R1

MOV PC, R0; PC = R0, the program jumps to the specified address

LDR R0, [R1],-R2; read the memory cell contents in the R1 address and stored in

R0, R1 = R1-R2

� Rm, shift - register shift mode.

The results of the shift register as the operand, the Rm value saved unchanged,

the shifting method is as follows:

ASR # n n-bit arithmetic shift right (1 ≤ n ≤ 32).

Logical Shift Left LSL # n n-bit (1 ≤ n ≤ 31).

LSR # n logical right by n bits (1 ≤ n ≤ 32).

Rotate Right ROR # n n-bit (1 ≤ n ≤ 31).

The RRX band extended rotate right one.](https://image.slidesharecdn.com/armembeddedsystemessentialszlg-230111081204-4bc9ad56/85/ARM-Embedded-System-Essentials-ZLG-docx-193-320.jpg)

![===================================================

-

67

CMPNE R1, # 20; If R0 10 R1 is 20

ADDNE R0, R0, R1; If R0 10 and R1 is not 20, the instruction execution, R0 = R0 +

R1

3 ARM memory access instructions

ARM processors are load / store architecture typical RISC processor, the

memory access can only use plus

Load and store instructions. ARM load / store instructions to achieve word, half-

word unsigned / signed byte operations; multi Send

Register load / store instruction is an instruction to load / store multiple

registers, greatly improving efficiency; SWP instruction

Is a register and the memory content switching instruction, and can be used for

the semaphore operation. The ARM processor is a von Neumann deposit

Storage structure, program space, RAM space and I / O mapping space unified

addressing, in addition to the operation of RAM on peripheral IO,

Program data access to be performed by load / store instructions.

ARM memory access instructions are shown in Table 4.2.

Table 4.2 ARM memory access instructions

Mnemonic instructions condition code location

LDR Rd, addressing word data is loaded Rd ← [addressing] addressing index LDR

{cond}

LDRB Rd, addressing load unsigned byte data Rd ← [addressing] addressing

index LDR {cond} B](https://image.slidesharecdn.com/armembeddedsystemessentialszlg-230111081204-4bc9ad56/85/ARM-Embedded-System-Essentials-ZLG-docx-197-320.jpg)

![LDRT Rd, addressing user mode loaded word data Rd ← [addressing] addressing

index LDR {cond} T

LDRBT Rd, addressing user mode to load unsigned byte data Rd ← [addressing]

addressing index LDR {cond} BT

LDRH Rd, addressing load unsigned halfword data Rd ← [addressing] addressing

index LDR {cond} H

LDRSB Rd, addressing load signed byte data Rd ← [addressing] addressing index

LDR {cond} SB

LDRSH Rd, addressing load signed halfword data Rd ← [addressing] addressing

index LDR {cond} SH

STR Rd, addressing storage word data [addressing] ← Rd, addressing index STR

{cond}

STRB Rd, addressing storage byte data [addressing] ← Rd, addressing index STR

{cond}

STRT Rd, addressing the user-mode memory word data [addressing] ← Rd

addressing index STR {cond} T

STRBT Rd, addressing bytes of data stored in user mode [addressing] ← Rd,

addressing index STR {cond} BT

The STRH Rd, addressing storage halfword data [addressing] ← Rd, addressing

index STR {cond} H

LDM {mode} Rn {!} Reglist must multiple register load reglist must ← [Rn ...], Rn

writeback LDM {cond} {mode}

STM {mode} Rn {!} Reglist must register storage [Rn ...] ← reglist must Rn

writeback STM {cond} {mode}

SWP Rd, Rm, Rn register and memory word data exchange Rd ← [Rn], [Rn] ←](https://image.slidesharecdn.com/armembeddedsystemessentialszlg-230111081204-4bc9ad56/85/ARM-Embedded-System-Essentials-ZLG-docx-198-320.jpg)

![Rm (Rn ≠ Rd or Rm) SWP {cond}

SWPB Rd, Rm, the Rn registers and memory byte data exchange Rd ← [Rn], [Rn]

← Rm (Rn ≠ Rd or Rm) SWP {cond} B

� LDR and STR - load-store instruction

Load / store word and unsigned byte instructions

STR instructions store a single byte or word LDR instruction loaded from

memory to memory, a single byte or word

Into the register. LDR instruction is used to read data from memory into a

register; STR instruction is used to register the number of

It is saved to memory. Instruction format is as follows:

LDR {cond} {T} Rd, <address>; load the specified address on the data (words) in

Rd

STR {cond} {T} Rd, <address>; storing data (word) to the specified address

storage unit, to store

; Data in Rd

LDR {cond} B {T} Rd, <address>; loading byte data in Rd Rd lowest byte

; Effective, 24 cleared

STR {cond} B {T} Rd, <address>; storage bytes of data, the data to be stored in

Rd, minimum word

; Festival effective

Wherein, T is an optional suffix. Instruction T, then even if the processor is in a

privileged mode, the storage system will also visit](https://image.slidesharecdn.com/armembeddedsystemessentialszlg-230111081204-4bc9ad56/85/ARM-Embedded-System-Essentials-ZLG-docx-199-320.jpg)

![===================================================

-

68

Asked as the processor is in user mode. T in user mode invalid and can not be

used in conjunction with T with the former index offset.

Instruction encoding format:

I, P, U, W is used to distinguish the address mode (offset). I offset 12 0:00

legislation

I.e. number; I is 1, the offset amount for the shift registers. P denotes the pre /

post indexed, U table

Shown in plus / minus, W indicates write-back.

L is used to distinguish load (L is 1) or storage (L 0).

B for distinction byte at (B 1) or wordwise (B 0).

Rn base register.

Rd source / destination register.

LDR / STR instruction addressing is very flexible and consists of two parts, a part

of a base register, you can

Any one of general purpose registers; another portion as an address offset. The

address offset of the following formats:

(1) immediate. Claim number may be an unsigned values. This data can be

added to the base register, you can also

This value is subtracted from the base register. Instructions for example as

follows:

LDR R1, [R0, # 0x12]; R0 +0 x12 at the address of the data read out, save to R1

; (R0 values unchanged)](https://image.slidesharecdn.com/armembeddedsystemessentialszlg-230111081204-4bc9ad56/85/ARM-Embedded-System-Essentials-ZLG-docx-200-320.jpg)

![LDR R1, [R0, #-0x12]; the R0-0x12 at the address data is read out, saved to the

R1

; (R0 values unchanged)

LDR R1, [R0]; the R0 address data read-out, saved into R1 (zero-offset)

(2) register. Register values can be added to the base register can also be

subtracted from the base register number

Value. Instructions for example as follows:

LDR R1, [R0, R2]; R0 + R2 at the address data is read out, saved to R1 (the value

of R0 unchanged)

LDR R1, [R0,-R2]; R0-R2 at the address of the data read out, saved to R1 (the

value of R0 unchanged)

(3) registers, and the shift constant. The value can be added to the base register,

register shift can also be from the base register

Subtracted this value. Instructions for example as follows:

LDR R1, [R0, R2, LSL # 2]; R0 + R2 × 4 address data read out, save it to R1

; (R0, R2 value of the same)

LDR R1, [R0,-R2, LSL # 2]; R0-R2 × 4 at the address of the data read out, saved to

the R1

; (R0, R2 value of the same)

From addressing modes of address points, load / store instructions have the

following form:

(1) zero offset. The value of Rn as the address of the transmission data, i.e., the

address offset is 0. Instructions for example as follows:

LDR Rd, [Rn]

(2) before the index offset. In the data before transmission, the offset is added](https://image.slidesharecdn.com/armembeddedsystemessentialszlg-230111081204-4bc9ad56/85/ARM-Embedded-System-Essentials-ZLG-docx-201-320.jpg)

![to Rn, and the result as a transmission data storage

Address. If the use of the suffix "!", The result is written back into Rn, and Rn

the value does not allow for the R15. Instructions for example as follows:

LDR Rd, [Rn, # 0x04]!

LDR Rd, [Rn, #-0x04]

(3) procedures relative offset. Procedures relative offset to form another

version of the former index. The assembler PC register

Count offset, and the PC register as Rn generated before the index command.

Can not use the suffix "!" Instructions for example as follows:

LDR Rd, label; label program label, label must be within ± 4KB current

instruction

(4) after the index offset. The value of Rn is used as the storage address of the

transmission data. After the data transfer, the offset amount with Rn

Added together, the result is written back into Rn. Rn not allowed to R15.

Instructions for example as follows:](https://image.slidesharecdn.com/armembeddedsystemessentialszlg-230111081204-4bc9ad56/85/ARM-Embedded-System-Essentials-ZLG-docx-202-320.jpg)

![===================================================

-

69

LDR Rd, [Rn], # 0x04

Address alignment - in most cases, must be guaranteed for 32 to send the

address is 32-bit aligned.

Load / store word and unsigned byte instruction for example as follows:

Loaded R5 specified data (word address) and put it into R2 LDR R2, [R5];

STR R1, [R0, # 0x04]; storage unit of the data storage of R1 to R0 +0 x04, R0

values unchanged

LDRB R3, [R2], # 1; read the R2 address of the one-byte data, and save it into R3,

R2 = R2 +1

STRB R6, [R7]; R6, data is saved to the address specified by R7, only store one

byte

; Data

Load / store halfword and signed byte

Such LDR / STR instruction can load signed byte load signed halfword load /

store unsigned halfword. Offset

The amount of formats, addressing modes, and load / store word and unsigned

byte instructions. Instruction format is as follows:

LDR {cond} SB Rd, <address>; load the address specified on the data (signed

byte) in Rd

LDR {cond} SH Rd, <address>; load the address specified on the data (signed

half-word) in Rd

LDR {cond} H Rd, <address>; Load halfword data in Rd 16 Rd lowest effective](https://image.slidesharecdn.com/armembeddedsystemessentialszlg-230111081204-4bc9ad56/85/ARM-Embedded-System-Essentials-ZLG-docx-203-320.jpg)

![; High 16 cleared

STR {cond} H Rd, <address>; store halfword data you want to store the data in

Rd, a minimum of 16

Description: sign bit halfword / byte loaded is loaded with sign bit extended to

32; unsigned bit halfword loads

Zero-extended to 32 bits.

Instruction encoding format:

I, P, U, W is used to distinguish the address mode (offset). I offset 8 0:00

legislation

That number; I 1:00, offset offset register. P denotes the pre / post indexed, U

table

Shown in plus / minus, W indicates write-back.

L is used to distinguish load (L is 1) or storage (L 0).

S used to distinguish the symbolic access (S 1) and unsigned access (S 0).

H is used to distinguish halfword access (H 1) or byte access (H 0).

Rn base register.

Rd source / destination register.

Address alignment - the halfword address must be an even number. Non

halfword aligned halfword loads Rd contents will not

Rely; half-word aligned the halfword storage will allow the specified address 2

bytes of storage unreliable.

Load / store halfword and signed byte instruction example as follows:

LDRSB R1, [R0, R3]; R0 + R3 is the address of the byte data read out to the R1,

the high-order 24 bits are the sign bit

; Expansion](https://image.slidesharecdn.com/armembeddedsystemessentialszlg-230111081204-4bc9ad56/85/ARM-Embedded-System-Essentials-ZLG-docx-204-320.jpg)

![LDRSH R1, [R9]; R9 address on the half-word data is read out to the R1, 16 high

sign bit extension

LDRH R6, [R2], # 2; R2 half-word data on the address read out to the R6, high-

order 16-bit zero-extended.

; R2 = R2 +2

STRH R1, [R0, # 2]!; Save data R1 to R0 +2 address, stores only the lower 2 bytes

of data,](https://image.slidesharecdn.com/armembeddedsystemessentialszlg-230111081204-4bc9ad56/85/ARM-Embedded-System-Essentials-ZLG-docx-205-320.jpg)

![===================================================

-

71

Register of the low numbers, and will save the initial value of Rn; Rn load value

and stored value in the other cases unpredictable.

Address alignment - these instructions to ignore address bit [1:0].

Multiple register load / store instructions for example as follows:

LDMIA R0!, {R3-R9}; multi-word data loaded on the address pointed to by R0,

saved to R3 to R9 in

; R0 value update

STMIA R1!, {R3-R9}; R3 ~ R9 data stored in the address pointed to by R1 R1

value update

STMFD SP!, {R0-R7, LR}; site to save the R0 ~~ R7, LR stack

LDMFD SP!, {R0-R7, PC} ^; site restoration, exception handling return

During data replication, to set a good source data pointer and target pointer,

and then use the block copy addressing instruction

LDMIA / STMIA, LDMIB / STMIB, LDMDA / STMDA, LDMDB / STMDB read and

stored.

And stack operations, first set up the stack pointer, general use of the SP, and

then use the stack addressing instructions

STMFD / LDMFD, STMED / LDMED, STMFA / LDMFA STMEA / LDMEA stack

operations.

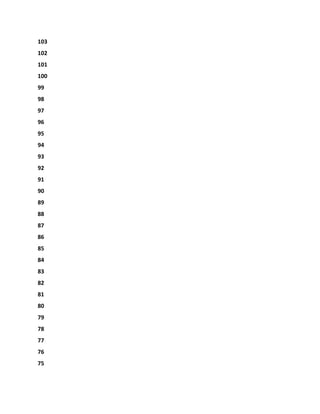

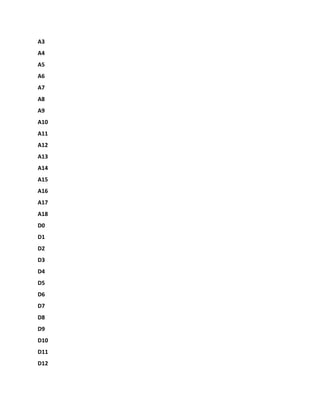

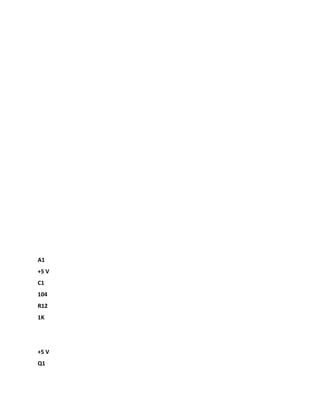

Multiple register transfer instruction is shown in Figure 4.2, where R1 is the

base register before the instruction execution, R1 'compared to

Instruction is executed after the base register.](https://image.slidesharecdn.com/armembeddedsystemessentialszlg-230111081204-4bc9ad56/85/ARM-Embedded-System-Essentials-ZLG-docx-209-320.jpg)

![Reduce

After LDMDA

LDMFA

STMDA

STMED

� SWP - exchange instruction register and memory

SWP instruction is used to read the contents of a memory unit (the unit address

on the register Rn) to a register

Rd, while another register Rm content is written to the memory unit. SWP

semaphore operations.

Instruction format is as follows:

SWP {cond} {B} Rd, Rm, [Rn]

Wherein, B is an optional suffix, if B, then the switch byte, otherwise exchanging

the 32-bit word; Rd for the data from the memory plus

Loaded into the register; data of Rm stored in the memory, and if Rm and Rn

same, compared to the registers and memory

Content to be exchanged; Rn want to exchange data memory address, Rn Rd

and Rm can not.

Instruction encoding format:

B is used to distinguish an unsigned byte (B 1) or word (B 0).

Rm source register.

Rd target register.

Rn base register.

SWP instruction for example as follows:

SWP R1, R1, [R0]; content to point to a memory cell the contents of R1 and R0 is](https://image.slidesharecdn.com/armembeddedsystemessentialszlg-230111081204-4bc9ad56/85/ARM-Embedded-System-Essentials-ZLG-docx-213-320.jpg)

![===================================================

-

73

SWPB R1, R2, [R0]; tolerance R0 points to a storage unit to read a byte of data

into R1 (high 24

;-Bit cleared), and R2 is written to the memory unit (lowest byte)

4 ARM data processing instruction

Data processing instructions can be broadly divided into three categories: data

transfer instruction (MOV, MVN), arithmetic logic operation instructions (such

as

ADD, SUB, AND), compare instructions (CMP, TST). Data processing instruction

operation only the contents of the register

For. All ARM data processing instruction can choose to use the S suffix, and

affect the status flags. Comparison instruction CMP, CMN,

TST and TEQ does not require suffix S, they will directly affect the status flags.

ARM data processing instructions are shown in Table 4.4.

Table 4.4 ARM data processing instruction

Mnemonic instructions condition code location

MOV Rd, operand2 data transmission Rd ← operand2 MOV {cond} {S}

The MVN Rd, operand2 data is non-transmission Rd ← (~ operand2) MVN

{cond} {S}

ADD Rd, Rn, operand2 addition instructions Rd ← Rn + operand2 the ADD

{cond} {S}

SUB Rd, Rn, operand2 subtraction instruction Rd ← Rn-operand2 SUB {cond} {S}

RSB Rd, Rn, operand2 the reverse subtraction Directive Rd ← operand2-Rn RSB](https://image.slidesharecdn.com/armembeddedsystemessentialszlg-230111081204-4bc9ad56/85/ARM-Embedded-System-Essentials-ZLG-docx-215-320.jpg)

![===================================================

-

81

BL DELAY

The branch instructions BL is limited within ± 32M byte address range of the

current instruction. The BL instruction for subroutine calls.

� BX - branch instruction with state switch

The BX instruction jumps to the address specified in the implementation of the

program in Rm, Rm the bit [0] to 1, jumps automatically to the CPSR

In logo T set target address of the code that is interpreted as Thumb code; Rm

the bit [0] is 0, then the jump

Automatically reset the flag in the CPSR T, that the code of the destination

address is interpreted as ARM code. Instruction format is as follows:

BX {cond} Rm

Instruction encoding format:

Rm destination address register.

State switching branch instruction BX for example as follows:

ADRL R0, ThumbFun +1

BX R0; jump to the designated address of the R0, and is switched in accordance

with the lowest bit of R0 at

; Processor state

7 ARM coprocessor instruction

ARM support the coprocessor operation, control coprocessor coprocessor

command.

ARM coprocessor instructions are shown in Table 4.9.](https://image.slidesharecdn.com/armembeddedsystemessentialszlg-230111081204-4bc9ad56/85/ARM-Embedded-System-Essentials-ZLG-docx-233-320.jpg)

![P, U, W is used to distinguish the address mode. P represents the before / after

index the U plus / minus, W

The write-back.

N data size (dependent on the co-processor).

LDC instruction for example as follows:

LDC p5, c2, [R2, # 4]; read R2 +4 points to the memory unit of the data sent to

the coprocessor

; P5 c2 register

LDC p6, c2, [R1]; R1 points to the memory unit is read data for delivery to the

coprocessor P6

; C2 register

� STC - coprocessor data write command

The STC instruction to coprocessor register data written to a contiguous

memory unit. Coprocessor data

The data transfer by the coprocessor to control the number of words

transmitted. Coprocessor can not successfully perform the operation, will

produce undetermined

Justice directive abort. Instruction format is as follows:

STC {cond} {L} coproc, CRd, <address>

Where: L Optional suffix, specified is long transfer.

coproc instruction coprocessor operation name. The standard named PN, n is 0

to 15.](https://image.slidesharecdn.com/armembeddedsystemessentialszlg-230111081204-4bc9ad56/85/ARM-Embedded-System-Essentials-ZLG-docx-238-320.jpg)

![===================================================

-

83

CRd as goal Storage coprocessor registers.

<Address> specified memory address.

Instruction encoding format:

cp_num coprocessor number.

8_bit_word_offset 8-bit immediate offset.

P, U, W is used to distinguish the address mode. P represents the before / after

index the U plus / minus, W

The write-back.

N data size (dependent on the co-processor).

STC instruction for example as follows:

STC p5, c1, [R0]

STC p5, c1, [R0, #-0x04]

� MCR - ARM register data transfer instructions to the coprocessor registers

MCR instruction ARM processor register data to the coprocessor registers. If the

co-processor is not

Able to successfully perform the operation, will produce undefined instruction

exception interrupt. Instruction format is as follows:

MCR {cond} coproc, opcode1, Rd, CRn, CRm {, opcode2}

Coprocessor name: coproc instruction operation. The standard named PN, n is 0

to 15.

specific opcode1 coprocessor opcode.

Rd as goal Storage coprocessor registers.](https://image.slidesharecdn.com/armembeddedsystemessentialszlg-230111081204-4bc9ad56/85/ARM-Embedded-System-Essentials-ZLG-docx-239-320.jpg)

![===================================================

-

85

MOV R0, # 12; soft interrupt call on the 12th

MOV R1, # 34; the Set subfunction number 34

SWI 0

The SWI exception interrupt handler, remove SWI immediate steps: First,

determine what caused the soft interrupt SWI

Instruction is the ARM instruction Thumb instruction, which can be get SPSR

access; then to get the SWI instruction

Address, which can be obtained by visiting the LR register; then read out the

instructions, decomposition immediate. As the program in Listing 4.2

Shows.

Program Listing 4.2 reads SWI immediate

T_bit EQU 0x20

SWI_Handler

STMFD SP!, {R0-R3, R12, LR}; site protection

MRS R0, SPSR; reads SPSR

STMFD SP!, {R0}; saved SPSR

TST R0, # T_bit; Testing T flag

LDRNEH R0, [LR, # -2]; if Thumb instructions, read the script (16)

Immediate BICNE R0, R0, # 0xFF00; obtain Thumb instruction 8

LDREQ R0, [LR, # -4]; ARM instruction to read the script (32)

24 BICEQ R0, R0, # 0xFF000000; made ARM instruction immediate

...](https://image.slidesharecdn.com/armembeddedsystemessentialszlg-230111081204-4bc9ad56/85/ARM-Embedded-System-Essentials-ZLG-docx-243-320.jpg)

![===================================================

-

86

Program Listing 4.3 enabled IRQ interrupt

ENABLE_IRQ

MRS R0, CPSR

BIC R0, R0, # 0x80

MSR CPSR_c, R0

MOV PC, LR

Disable IRQ interrupt the program list 4.4

DISABLE_IRQ

MRS R0 CPSR

ORR R0, R0, # 0x80

MSR CPSR_c, R0

MOV PC, LR

� MSR - write status register instruction

ARM processor, only MSR instructions can set the status register CPSR or the

SPSR. Instruction format

As follows:

MSR {cond} psr_fields, # immed_8r

MSR {cond} psr_fields, Rm

Among them: psr CPSR or SPSR.

fields specify a region of the transfer. The fields can be the following one or

more (letters must be lowercase):

c control the domain shielded byte (psr [7 ... 0]);](https://image.slidesharecdn.com/armembeddedsystemessentialszlg-230111081204-4bc9ad56/85/ARM-Embedded-System-Essentials-ZLG-docx-245-320.jpg)

![the x extension field mask byte (psr [15 ... 8]);

s status the domain shielded bytes (psr [23 ... 16]);

The f flag Domain mask byte (psr [31 ... 24]).

immed_8r to be sent to a status register domain specified immediate 8.

Rm be sent to the the status register domain specified data source register.

Instruction encoding format (operand immediate):

Instruction encoding format (operand register):

R for distinction CPSR (R, 0) or the SPSR (R as 1).

field_mask domain shielding.

rotate_imm immediate alignment.

8_bit_immediate 8-bit immediate data.

Rm operand register.

MSR instruction for example as follows:

MSR CPSR_c, # 0xD3; CPSR [7 ... 0] = 0xD3, switch to the management mode

MSR CPSR_cxsf, R3; CPSR = R3](https://image.slidesharecdn.com/armembeddedsystemessentialszlg-230111081204-4bc9ad56/85/ARM-Embedded-System-Essentials-ZLG-docx-246-320.jpg)

![===================================================

-

88

4.6 small range of program listings address the load

...

ADR R0, DISP_TAB; conversion table is loaded address

LDRB R1, [R0, R2]; using R2 as a parameter for look

...

DISP_TAB

DCB 0xC0, 0xF9, 0xA4, 0xB0, 0x99, 0x92, 0x82, 0xF8, 0x80, 0x90

� ADRL - the mid-range of the address read directive

The ADRL instruction will PC relative offset address value-based, or based on

the relative offset of the register address value read to register

Than ADR directive can be read by a wider address. Assembler source code,

ADRL directive is compiled

Replace two appropriate instruction. If two instructions can be used to achieve

ADRL pseudo-instruction, an error is generated, compiled

Fail. ADRL pseudo-instruction format is as follows:

ADRL {cond} register, expr

Among them: register load target register.

The Expr address expressions. When the non-word-aligned address value, the

range-64KB ~ 64KB between;

When the value of the address is word-aligned, the range-256KB ~ 256KB

between.

The ADRL directive for example as follows:](https://image.slidesharecdn.com/armembeddedsystemessentialszlg-230111081204-4bc9ad56/85/ARM-Embedded-System-Essentials-ZLG-docx-250-320.jpg)

![===================================================

-

89

Procedural relative offset LDR instruction read out from the text pool constant.

LDR pseudo-instruction format is as follows:

LDR {cond} register, = expr / label-expr

Among them: register load target register.

expr 32-bit immediate data.

label-expr expressions or external PC-based address expressions.

The directive of LADR example is as follows:

LDR R0, = 0x12345678; load 32-bit immediate data 0x12345678

LDR R0, = DATA_BUF +60; to load DATA_BUF address +60

...

LTORG; statement text pool

...

Directive LDR commonly used in the loaded chip peripheral features register

address (32-bit immediate data) in order to achieve a variety of control

System operation, such as the program shown in Listing 4.8.

Program list 4.8 to load the 32-bit immediate data

...

LDR R0, = IOPIN; the register IOPIN loaded GPIO address

LDR R1, [R0]; read IOPIN register value

...

LDR R0, = IOSET

LDR R1, = 0x00500500](https://image.slidesharecdn.com/armembeddedsystemessentialszlg-230111081204-4bc9ad56/85/ARM-Embedded-System-Essentials-ZLG-docx-253-320.jpg)

![STR R1, [R0]; IOSET = 0x00500500

...

Offset from the PC to the text pool must be less than 4KB.

Compared with the ARM instruction LDR LDR pseudo-instruction parameters "="

sign.

� NOP - No operation directive

The NOP directive in the assembly will be replaced by the empty operating in

ARM, for example, might refer to as "MOV R0, R0"

So. NOP directive format is as follows:

NOP

NOP can be used to delay the operation, as shown in the list of procedures 4.9.

Program list 4.9 software delay

...

DELAY1

NOP

NOP

NOP

SUBS R1, R1, # 1

BNE DELAY1](https://image.slidesharecdn.com/armembeddedsystemessentialszlg-230111081204-4bc9ad56/85/ARM-Embedded-System-Essentials-ZLG-docx-254-320.jpg)

![CODE32

ARM_CODE ADR R0, THUMB_CODE +1

BX R0; jump and switch the processor state

CODE16

THUMB_CODE

MOV R0, # 10; R0 = 10

MOV R1, # 20; R1 = 20

ADD R0, R1; R0 = R0 + R1

B.

END

The program first ARM state "ADR R0, THUMB_CODE +1" directive loading

Address THUMB_CODE order to R0 bit [0], so the use of "THUMB_CODE +1 such

BX is used to switch the processor state to Thumb state.

1. Thumb instruction set ARM instruction set difference

Thumb instruction set does not have a coprocessor instruction, the semaphore

instruction as well as access to the CPSR or SPSR instruction did not take

Plus instructions and 64-bit multiply instruction, the second operand and

instruction is limited; perform functions conditional branch instruction B

Can, other instructions are unconditional implementation; most Thumb data

processing instructions using address format. Thumb refers to

The difference between the set and the ARM instruction set is generally the

following points:

� branch instruction

Procedures relative shift, especially compared to the conditional jump jump

ARM code, there are more restrictions on the range,](https://image.slidesharecdn.com/armembeddedsystemessentialszlg-230111081204-4bc9ad56/85/ARM-Embedded-System-Essentials-ZLG-docx-256-320.jpg)

![Mnemonic instructions affect the flag

LDR Rd, [Rn, # immed_5 × 4] the loaded words Rd ← [Rn, of # immed_5 4] Rd, Rn R0 ~ R7 no

LDRH Rd, [Rn, # immed_5 × 2] load unsigned halfword data Rd ← [Rn, of # immed_5 × 2] Rd,

Rn R0 ~ R7 no

LDRB Rd, [Rn, # immed_5 × 1] load signed byte data Rd ← [Rn of # immed_5 × 1], Rd, Rn R0 ~

R7 no

STR Rd, [Rn, # immed_5 × 4] storing word data [Rn, # immed_5 × 4] ← Rd, Rd, Rn R0 ~ R7 no

STRH Rd, [Rn, # immed_5 × 2] storage signed halfword data [Rn of # immed_5 × 2] ← Rd, Rd,

Rn, R0 ~ R7 no

STRB Rd, [Rn, # immed_5 × 1] unsigned byte data storage [Rn, # immed_5 × 1] ← Rd, Rd, Rn,

R0 ~ R7 no

LDR Rd, [Rn, Rm] load word data Rd ← [Rn, Rm] Rd, Rn, Rm R0 ~ R7

LDRH Rd, [Rn, Rm] load signed halfword data Rd ← [Rn, Rm] Rd, Rn, Rm R0 ~ R7

LDRB Rd, [Rn, Rm] load signed byte data Rd ← [Rn, Rm, Rd, Rn, Rm R0 ~ R7 free

LDRSH Rd, [Rn, Rm] load signed halfword data Rd ← [Rn, Rm] Rd, Rn, Rm R0 ~ R7 no

LDRSB Rd, [Rn, Rm] load signed byte data Rd ← [Rn, Rm] Rd, Rn, Rm R0 ~ R7 no

STR Rd, [Rn, Rm] store word data [Rn, Rm] ← Rd, Rd, Rn, Rm R0 ~ R7

STRH Rd, [Rn, Rm] store unsigned halfword data [Rn, Rm ← Rd, Rd, Rn, Rm R0 ~ R7 None

STRB Rd, [Rn, Rm] the storage unsigned byte data [Rn, Rm ← Rd, Rd, Rn, Rm R0 ~ R7 None

LDR Rd, [PC, # immed_8 × 4] based on the the PC loaded word data Rd ← [the PC of #

immed_8 × 4] Rd R0 ~ R7 no

LDR Rd, label-based PC loaded word data Rd ← [label] Rd R0 ~ R7 no

LDR Rd, [SP, # immed_8 × 4] SP loaded word data Rd ← [SP of # immed_8 × 4] Rd R0 ~ R7 no

STR Rd, [SP, # immed_8 × 4] the the SP memory word data [SP, # immed_8 × 4] ← Rd Rd R0 ~

R7 no

LDMIA Rn {!}, Reglist multiple register load reglist must ← [Rn ...] Rn write-back (R0 ~ R7)

STMIA Rn {!}, Reglist multi-register storage [Rn ...] the ← in reglist, Rn write-back (R0 ~ R7)

PUSH {reglist [, LR]} register stack instruction [SP ...] ← reglist must [LR] SP writeback (R0 ~~

R7, LR) free](https://image.slidesharecdn.com/armembeddedsystemessentialszlg-230111081204-4bc9ad56/85/ARM-Embedded-System-Essentials-ZLG-docx-259-320.jpg)

![POP {reglist [, PC]} register the stack instruction reglist must [PC] ← [SP ...] SP write-back, etc.

(R0 ~~ R7, PC) free](https://image.slidesharecdn.com/armembeddedsystemessentialszlg-230111081204-4bc9ad56/85/ARM-Embedded-System-Essentials-ZLG-docx-260-320.jpg)

![==================================================

-

92

� LDR and STR - load / store instructions

Immediate offset LDR and STR instructions.

Memory address specified immediate offset to a register. Instruction format is as follows:

Load the specified address on the data (words) in Rd LDR Rd, [Rn, # immed_5 × 4];

STR Rd, [Rn, # immed_5 × 4]; storing data (word) to the specified address storage unit, to

store data in Rd

LDRH Rd, [Rn, # immed_5 × 2]; load half-word data in Rd, Rd lowest 16 high 16 cleared

STRH Rd, [Rn, # immed_5 × 2]; store halfword data you want to store the data in Rd, a

minimum of 16

Loading byte data LDRB Rd, [Rn, # immed_5 × 1]; placed Rd Rd lowest byte high 24 cleared

STRB Rd, [Rn, # immed_5 × 1]; storage bytes of data, the data to be stored in Rd, least

significant byte

Where: Rd load or store register. Must R0 ~ R7.

Rn base register. Must R0 ~ R7.

immed_5 × N offset. It is an unsigned immediate expression, its value (0 to 31) × N.

Half-word and byte load immediate offset is unsigned. The least significant halfword or byte

of data is loaded into Rd, Rd

The remaining bits make up 0.

Instruction encoding format (LDR / STR Rd, [Rn, # immed_5 × 4]):

The instruction encoding. Format (LDRH / STRH Rd, [Rn, # immed_5 x 2]):

Instruction encoding format (LDRB / STRB Rd, [Rn, # immed_5 × 1]):

L is used to distinguish load (L is 1) or storage (L 0).

immed_5 5-bit unsigned immediate offset.

Address alignment - word transfer, must ensure that send address 32 alignment. Halfword,

must ensure that the transmission

The address is 16-bit aligned.](https://image.slidesharecdn.com/armembeddedsystemessentialszlg-230111081204-4bc9ad56/85/ARM-Embedded-System-Essentials-ZLG-docx-261-320.jpg)

![Immediate offset LDR and STR instructions for example as follows:

LDR R0, [R1, # 0x4]

STR R3, [R4]

LDRH R5, [R0, # 0x02]

STRH R1, [R0, # 0x08]

LDRB R3, [R6, # 20]

STRB R1, [R0, # 31]

Register offset LDR and STR instructions. The memory address is specified in a register of the

register offset.

Instruction format is as follows:

LDR Rd, [Rn, Rm]; loading a word data

STR Rd, [Rn, Rm]; storing word data

LDRH Rd, [Rn, Rm]; load an unsigned halfword data](https://image.slidesharecdn.com/armembeddedsystemessentialszlg-230111081204-4bc9ad56/85/ARM-Embedded-System-Essentials-ZLG-docx-262-320.jpg)

![==================================================

-

93

STRH Rd, [Rn, Rm]; store an unsigned halfword data

LDRB Rd, [Rn, Rm]; load an unsigned byte data

STRB Rd, [Rn, Rm]; store an unsigned byte data

LDRSH Rd, [Rn, Rm]; loads a signed halfword data

LDRSB Rd, [Rn, Rm]; store a signed halfword data

Where: Rd load or store register. Must R0 ~ R7.

Rn base register. Must R0 ~ R7.

Rm contains the offset register. Must R0 ~ R7.

Register load half-word and byte offset can be signed or unsigned, the data is loaded to the

lowest effective Rd half

Word or byte. Signed halfword or byte loaded Rd remaining bits of zeros; signed halfword or

byte loaded

Rd remaining bits of copy the sign bit.

Instruction encoding format (LDR / STR Rd, [Rn, Rm):

The instruction encoding. Format (LDRH / STRH Rd, [Rn, Rm):

Instruction encoding format (LDRB / STRB Rd, [Rn, Rm):

Instructions encoding format (LDRSH Rd, [Rn, Rm]):

Instruction encoding format (The action of the LDRSB Rd, [Rn, Rm]):

L is used to distinguish load (L is 1) or storage (L 0).

Address alignment - word transfer, must ensure that send address 32 alignment. Halfword,

must ensure that the transmission

The address is 16-bit aligned.

Register offset LDR and STR instructions for example as follows:

LDR R3, [R1, R0]

STR R1, [R0, R2]

LDRH R6, [R0, R1]](https://image.slidesharecdn.com/armembeddedsystemessentialszlg-230111081204-4bc9ad56/85/ARM-Embedded-System-Essentials-ZLG-docx-263-320.jpg)

![STRH R0, [R4, R5]

LDRB R2, [R5, R1]

STRB R1, [R3, R2]

LDRSH R7, [R6, R3]

LDRSB R5, [R7, R2]](https://image.slidesharecdn.com/armembeddedsystemessentialszlg-230111081204-4bc9ad56/85/ARM-Embedded-System-Essentials-ZLG-docx-264-320.jpg)

![==================================================

-

94

PC or SP relative offset LDR and STR instructions. To refer to the value in the PC or the SP

register immediate offset

Address tomorrow memory. Instruction format is as follows:

LDR Rd, [PC, # immed_8 × 4]

LDR Rd, label

LDR Rd, [SP, # immed_8 × 4]

STR Rd, [SP, # immed_8 × 4]

Where: Rd load or store register. Must R0 ~ R7.

immed_8 × 4 offset. It is an unsigned immediate expression, its value (0 to 255) × 4.

label program relative offset expressions. label must be in the current instruction within 1KB.

Instruction encoding format (PC relative offset LDR instruction):

Instruction encoding format (SP relative offset LDR / STR instruction):

L is used to distinguish load (L is 1) or storage (L 0).

immed_8 8-bit unsigned immediate offset.

Address alignment - address must be an integer multiple of 4.

PC or SP relative offset LDR and STR instructions for example as follows:

LDR R0, [PC, # 0x08]; reads PC +0 x08 word on the address data, saved to R0

LDR R7, LOCALDAT; to read word LOCALDAT address data saved in R7

LDR R3, [SP, # 1020]; SP +1020 address is read word data, save to R3

STR R2, [SP]; storage R2 register data to the SP points to the storage unit (offset 0)

� PUSH and POP - register onto the stack, and the stack instruction

Low register and optional the LR register stack and low registers and optional PC register and

pop operations. Stack

The address is set by the SP register, the stack is full descending stack. Instruction format is as

follows:

PUSH {reglist [, LR]}](https://image.slidesharecdn.com/armembeddedsystemessentialszlg-230111081204-4bc9ad56/85/ARM-Embedded-System-Essentials-ZLG-docx-265-320.jpg)

![POP {reglist [, PC]}

Where: reglist stack / the the stack low register list that R0 ~~ R7.

The LR Ruzhan optional register.

PC optional register stack.

Instruction encoding format:

L is used to distinguish the stack (L 1) or a stack (L 0).

R difference operation register whether LR / PC (there are, then R = 1, and 0 otherwise).

Register onto the stack, and the stack command example is as follows:](https://image.slidesharecdn.com/armembeddedsystemessentialszlg-230111081204-4bc9ad56/85/ARM-Embedded-System-Essentials-ZLG-docx-266-320.jpg)

![==================================================

-

108

� BL - connected with the branch instruction

The link register BL instruction is copied to the first address of the next instruction R14 (LR),

then jumps to the specified address

Run the program. Instruction format is as follows:

BL label

Instruction encoding format:

H distinction ± 4MB of 11 high offset (H, 0) or low 11 offset (H 1).

To achieve this due to the BL instruction normally requires a large address range, it is difficult

to use the 16-bit instruction format, Thumb

The combination of two such instruction into 22 half-word offset (sign extended to 32), so

that the instruction transfer range of ± 4MB.

The link branch instruction BL for example as follows:

BL DELAY1

The machine level branch instructions BL limit, when necessary, within the scope of the

current instruction ± 4MB ARM linker insertion substituting

Code to allow a longer transfer.

� BX - branch instruction with state switch

The BX jump to the address specified in the implementation of the program in Rm. If Rm bit

0, Rm bit [0] [1] must be 0.

Jump automatically when the flags in the CPSR T reset, that is, the code of the destination

address is interpreted as ARM code. Instruction format, such as

Follows:

BX Rm

Instruction encoding format:

H for the difference between the high register (H 1) or low register (H 0).

State switching branch instruction BX for example as follows:](https://image.slidesharecdn.com/armembeddedsystemessentialszlg-230111081204-4bc9ad56/85/ARM-Embedded-System-Essentials-ZLG-docx-292-320.jpg)

![==================================================

-

110

LDR pseudo-instruction for example as follows:

LDR R0, = 0x12345678; load 32-bit immediate data 0x12345678

LDR R0, = DATA_BUF +60; to load DATA_BUF address +60

...

LTORG; statement text pool

...

Offset from the PC to the literal pool must be positive and less than 1KB.

Compared with the the Thumb instruction of LDR the directive LDR parameters "=" sign.

� NOP - No operation directive

The NOP directive in the assembly will be replaced by the empty operating in ARM, for

example, may MOV R0, R0 instruction

And so on. NOP directive format is as follows:

NOP

NOP can be used to delay the operation.

2.6 Chapter Summary

This chapter details the premium described in the ARM instruction set, Thumb instruction set,

and are listed in the instruction encoding format and related

Application examples, so that readers have a comprehensive understanding of the

ARM7TDMI (-S) command system.

Thinking and practice

1 basics

a) ARM7TDMI (-S) has several addressing modes? LDR R1, [R0, # 0x08] belongs Which

Addressing way?

b) ARM instruction condition code number? default condition code?

c) ARM instruction second operand which several forms? cited 5 8 Figure immediate.

d) LDR / STR instruction offset form which four kinds? LDRB, and LDRSB What is the](https://image.slidesharecdn.com/armembeddedsystemessentialszlg-230111081204-4bc9ad56/85/ARM-Embedded-System-Essentials-ZLG-docx-296-320.jpg)

![==================================================

-

111

Numbers, resulting flag then how are we to understand?

0xFFFF000F 0x7FFFFFFF 67654321 (A)

+ 0x0000FFF1 + 0x02345678 + 23110000 (B)

Results: () () ()

3 Data Access

The following C code into assembly code. Arrays a and b are each stored in at 0x4000 and

0x5000 as a starting

The address of the storage area, type long (32-bit). Written in assembly language compiled

connect and debug.

for (i = 0; i <8; i + +)

{A [i] = b [7-i];

}

4 factorial

Calculating the factorial of a number n, i.e. n = n * (the n-1) * (n-2) ... (1).

Given the value of n, the entire algorithm is constantly multiplier less a value obtained by

multiplying the previous time so that the current value, where said

The current value that is the result of the multiplication. The program continuously loops

perform multiplication operation, each cycle first multiplier minus one, if proceeds

A value of 0 cycle ends. Thinking to do multiplication in the program, the use of conditional

execution. In writing containing the circulation and transfer instruction

A program, since the Z flag to quickly determine whether to reach the number of cycles, many

programmers typically use a non-

Down the number of zero counts rather than the method of counting up to start the program.

Please fill the following code snippet, and add the appropriate paragraph statement, and

then debug the program correctness. Setting the value of n

Of 10, indicating that the results of program execution and observation program runs before](https://image.slidesharecdn.com/armembeddedsystemessentialszlg-230111081204-4bc9ad56/85/ARM-Embedded-System-Essentials-ZLG-docx-298-320.jpg)

![==================================================

-

135

Each chip startup code very different, is not easy to write a unified startup code. The ADS

strategy does not provide complete

Startup code. The boot code is less than or supplied by the manufacturer, or write your own.

Startup code and chip characteristics

Close ties later chapters will be introduced according to the characteristics of the chip

LPC2100, LPC2200 startup code.

ARM chip reset, the system enters the management mode ARM state, PC (R15) register value

0x00000000

It is necessary to ensure that the user to scale code positioned at 0x00000000 mapped to

0x00000000 (such

To scale code 0x80000000, through memory-mapped access 0x0000000 0x800000000).

LPC2114/2124/2210/2212/2214 startup code, to the definition of the scale as the list of

procedures 5.1 (in startup.s

File).

Program Listing 5.1 exception vector

CODE32

AREA vectors, CODE, READONLY

ENTRY

Reset

LDR PC, ResetAddr (1)

LDR PC, UndefinedAddr (2)

LDR PC, SWI_Addr (3)

LDR PC, PrefetchAddr (4)

LDR PC, DataAbortAddr (5)

DCD 0xb9205f80 (6)

LDR PC, [PC, #-0xff0] (7)](https://image.slidesharecdn.com/armembeddedsystemessentialszlg-230111081204-4bc9ad56/85/ARM-Embedded-System-Essentials-ZLG-docx-357-320.jpg)

![==================================================

-

141

Program Listing 5.4 scale and instruction machine code

Reset

[0xe59ff018] LDR PC, ResetAddr

[0xe59ff018] LDR PC, UndefinedAddr

[0xe59ff018] LDR PC, SWI_Addr

[0xe59ff018] LDR PC, PrefetchAddr

[0xe59ff018] LDR PC, DataAbortAddr

[0xb9205f80] DCD 0xb9205f80

[0xe51ffff0] LDR PC, [PC, #-0xff0]

[0xe59ff018] LDR PC, FIQ_Addr

32 to scale all data accumulation and:

0xe59ff018 + 0xe59ff018 +0 xe59ff018 + 0xe59ff018 + 0xe59ff018 + 0xb9205f80 +

0xe51ffff0 + 0xe59ff018 = 0x00000000

To calculate the value of reserved words in the scale (where "~" is negated code):

~ (0xe59ff018 + 0xe59ff018 +0 xe59ff018 + 0xe59ff018 + 0xe59ff018 + 0xe51ffff0 +

0xe59ff018) + 1 = 0xb9205f80

Reset](https://image.slidesharecdn.com/armembeddedsystemessentialszlg-230111081204-4bc9ad56/85/ARM-Embedded-System-Essentials-ZLG-docx-371-320.jpg)

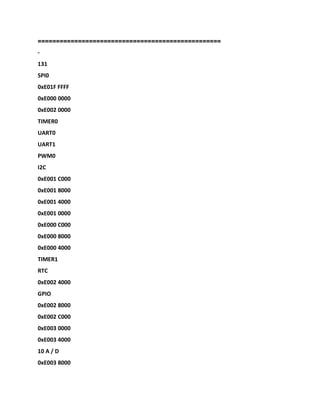

![239

: Vectors LDR PC, Reset_Addr

0x00000000 E59FF018 LDR PC,[PC,#0x0018]

240

: LDR PC, Undef_Addr

0x00000004 E59FF018 LDR PC,[PC,#0x0018]

241

: LDR PC, SWI_Addr

0x00000008 E59FF018 LDR PC,[PC,#0x0018]

242

: LDR PC, PAbt_Addr

0x0000000C E59FF018 LDR PC,[PC,#0x0018]

243

: LDR PC, DAbt_Addr

0x00000010 E59FF018 LDR PC,[PC,#0x0018]

244

: NOP ; Reserved Vector

245

; : LDR PC, IRQ_Addr

0x00000014 E1A00000 NOP

246

: LDR PC, [PC, #-0x0FF0] ; Vector from VicVectAddr

0x00000018 E51FFFF0 LDR PC,[PC,#-0x0FF0]

247

: LDR PC, FIQ_Addr

248

:

249

: Reset_Addr DCD Reset_Handler

250

: Undef_Addr DCD Undef_Handler

251

: SWI_Addr DCD SWI_Handler

252

: PAbt_Addr DCD PAbt_Handler

253

: DAbt_Addr DCD DAbt_Handler

254

: DCD 0 ; Reserved Address

255

: IRQ_Addr DCD IRQ_Handler

256

: FIQ_Addr DCD FIQ_Handler

257

:

0x0000001C E59FF018 LDR PC,[PC,#0x0018]

0x00000020 00000058 DD 0x00000058

0x00000024 00000040 DD 0x00000040

0x00000028 00000044 DD 0x00000044

0x0000002C 00000048 DD 0x00000048

0x00000030 0000004C DD 0x0000004C

0x00000034 00000000 DD 0x00000000

0x00000038 00000050 DD 0x00000050

0x0000003C 00000054 DD 0x00000054](https://image.slidesharecdn.com/armembeddedsystemessentialszlg-230111081204-4bc9ad56/85/ARM-Embedded-System-Essentials-ZLG-docx-372-320.jpg)

![258

:

Undef_Handler B Undef_Handler

0

x00000040 EAFFFFFE B 0x00000040

259

:

SWI_Handler B SWI_Handler

0

x00000044 EAFFFFFE B 0x00000044

260

:

PAbt_Handler B PAbt_Handler

0

x00000048 EAFFFFFE B 0x00000048

261

:

DAbt_Handler B DAbt_Handler

0

x0000004C EAFFFFFE B 0x0000004C

262

:

IRQ_Handler B IRQ_Handler

0

x00000050 EAFFFFFE B 0x00000050

263

:

FIQ_Handler B FIQ_Handler

0

x00000054 EAFFFFFE B 0x00000054

317

:

LDR R0, =PLL_BASE

0

x00000058 E59F00A0 LDR R0,[PC,#0x00A0

]

318

:

MOV R1, #0xAA

0

x0000005C E3A010AA MOV R1,#0x000000AA

319

:

MOV R2, #0x55

Initialization

Watchdog reset?

Depending on the hardware configuration

(P1.20, P1.26)

P0.14 is low?](https://image.slidesharecdn.com/armembeddedsystemessentialszlg-230111081204-4bc9ad56/85/ARM-Embedded-System-Essentials-ZLG-docx-373-320.jpg)

![============================

======================

-

147

When RESET is low for the LPC2210/2212/2214, the BOOT1: 0 feet of state control to guide

the way, see Table

5.17. If a pin is not connected, the receiver's internal pull guarantee its high state. Designers

can connect a

To select some weak pull-down resistor (4.7kΩ) or transistor (RESET is low for low drive) to

BOOT1: 0 feet

Boot.

Table 5.17 BOOT1: 0 boot control (LPC2210/2212/2214)

P2.27/D27/BOOT1 P2.26/D26/BOOT0 guide the way MAP1: 0

0 0 CS0 control 8-bit memory 11

16 0 1 CS0 control memory 11

0 CS0 control 32 memory 11

11 internal Flash memory 01

Note the use of the memory-mapped control

Memory-mapped control just necessary from the abnormal processing ARM three data

sources (ie, the exception vector 64 bytes)

Select a use, for LPC2210/2212/2214 the four data sources, as shown in Figure 5.16.

For example, each time to produce a software interrupt request ARM kernel data removed

from 0x00000008 at 32. This

Means when MEMMAP [1:0] = 10 (User RAM mode) from 0x00000008 readings / fetch

0x4000

0008 unit operates. If the MEMMAP [1:0] = 01 (User Flash mode), from 0x00000008 readings

/ take

Means to operate the unit 0x00000008 chip Flash. When MEMMAP [1:0] = 00 (Boot Loader

Mode)

When, from the the 0x00000008 readings / fetch (Boot Block operate 0x7FFFE008 unit of data](https://image.slidesharecdn.com/armembeddedsystemessentialszlg-230111081204-4bc9ad56/85/ARM-Embedded-System-Essentials-ZLG-docx-388-320.jpg)

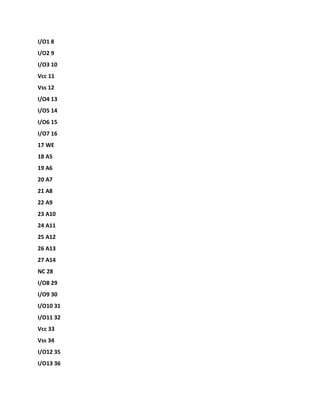

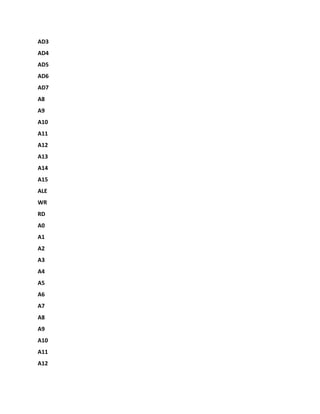

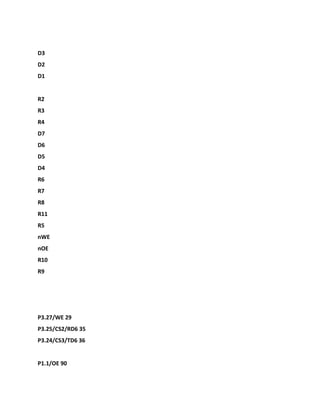

![====================

==============================

-

149

CCO

FOSC

PLOCK

Bypass

msel <4:0>

M divider

pd

MSEL [4:0]

PSEL [1:0]

fout

cd

1

0

1

cd

/ 2P

PLLC

Direct

PLLE

cclk

FCCO

pd

0

pd

0

1](https://image.slidesharecdn.com/armembeddedsystemessentialszlg-230111081204-4bc9ad56/85/ARM-Embedded-System-Essentials-ZLG-docx-393-320.jpg)

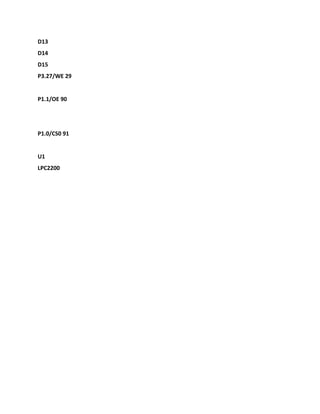

![Write MSEL

Bit value M-1 (see Table 5.25).

� value for P to configure the PSEL bits. By setting the P value FCCO within a defined

frequency limits, FCCO

Can be calculated by the preceding equation. P must be 1, 2, 4 or 8 wherein a. Written to the

PSEL bit values correspond

P-values are shown in Table 5.24.

Table 5.24 PLL divider value

PSEL bit PLLCFG [6:5] P value

00 1

012

104

118

Table 5.25 PLL multiplier value

MSEL bit PLLCFG [4:0] M values

000,001

000,012

000,103

000,114

......

1111031

1111132](https://image.slidesharecdn.com/armembeddedsystemessentialszlg-230111081204-4bc9ad56/85/ARM-Embedded-System-Essentials-ZLG-docx-401-320.jpg)

![==================================================

-

153

PLL set the example.

For example, the system requirements Fosc = 10MHz, cclk = 60MHz.

Based on these requirements can be drawn from the M = cclk / Fosc = 60MHz/10MHz = 6.

Thus, M-1 = 5 write

PLLCFG4: 0.

P values may be P = Fcco / (cclk * 2) derived, Fcco must 156MHz ~ 320MHz within. Assuming

the Fcco take the lowest frequency

The rate of 156MHz, then P = 156MHz / (2 * 60MHz) = 1.3. Fcco take the highest frequency

can be drawn from P = 2.67. Therefore, at the same time

P values satisfy Fcco lowest and highest frequency requirements is only up to 2, as shown in

Table 5.24. So, PLLCFG [6:5] = 01.

5.4.10 VPB divider

1 Description

The VPB Divider decided the relationship between the processor the clock (cclk) and

peripheral devices used by the clock (pclk). VPB

Divider serves two purposes, first by the VPB bus for peripherals the required pclk clock to

peripherals at the right

Speed work. In order to achieve this purpose, the VPB bus can be reduced to 1/2 or 1/4 of the

processor clock rate. Because the VPB

Bus must work properly after power (and when the the VPB divider controller is located VPB

bus leaving on electric

The VPB bus does not work, its timing can not be changed), the VPB bus after reset the

default state in the 1/4 speed run.

The VPB Divider second purpose is to reduce power consumption when the application does

not require any peripherals run at full speed.

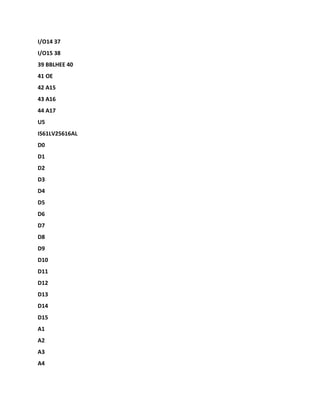

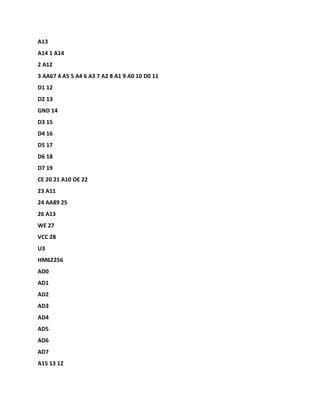

VPB divider and oscillator and the processor clock connection shown in Figure 5.18. VPB](https://image.slidesharecdn.com/armembeddedsystemessentialszlg-230111081204-4bc9ad56/85/ARM-Embedded-System-Essentials-ZLG-docx-402-320.jpg)

![divider is connected to the output of the PLL

PLL remains active (in the idle mode if the PLL is running).

PLL

(Fosc)

VPB divider

(Cclk)

(Pclk)

Crystal or external clock source processor clock

VPB clock

Figure 5.18 VPB divider connected

2. VPBDIV register (the VPBDIV - 0xE01FC100)

The VPB divider registers are described in Table 5.26. VPBDIV [1:0] two bits can be set to

three sub-frequency values as shown in Table

5.27. Effectively XCLKDIV in LPC2210/2212/2214.

Table 5.26 VPBDIV register map

Address Name Description Access

0xE01FC100 VPBDIV control the relationship between the the VPB clock rate of the processor

clock R / W

The Table 5.27 VPBDIV register

VPBDIV Function Description Reset value

1:0 VPBDIV VPB clock rate is as follows:

00: VPB bus clock is 1/4 of the processor clock.

01: VPB bus clock is the same as the processor clock.

10: VPB bus clock is 1/2 of the processor clock.