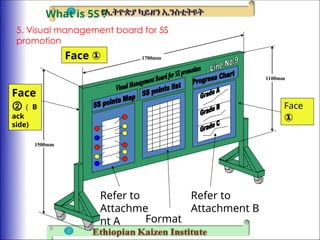

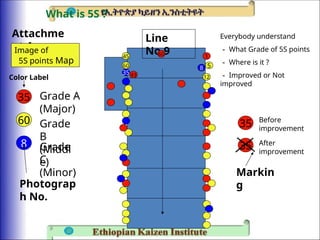

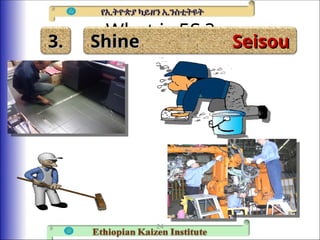

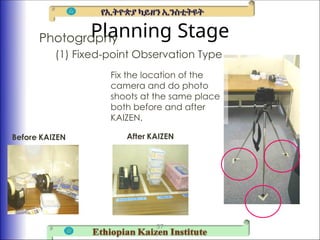

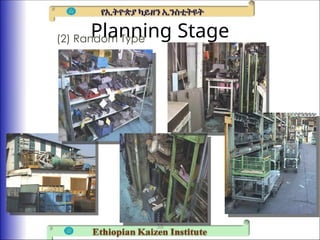

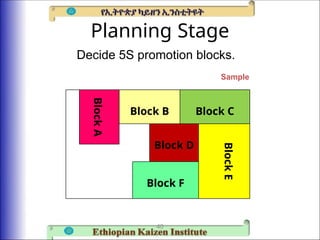

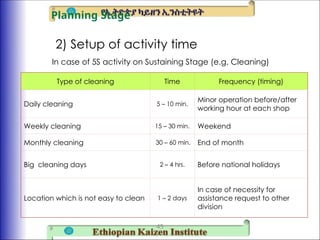

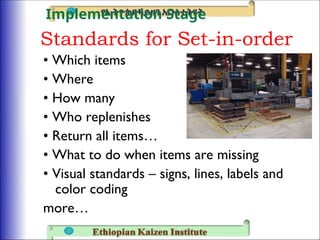

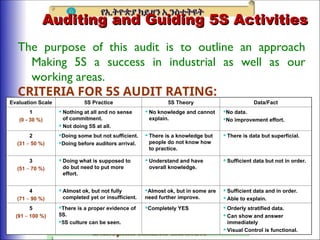

The document outlines the 5S program, which aims to improve workplace efficiency through five key principles: Sort, Set-in-order, Shine, Standardize, and Sustain. It emphasizes the importance of involving all employees in creating a productive and organized work environment, and provides guidance on planning, implementing, and sustaining these practices. Ultimately, the goal is to develop a culture of continuous improvement and operational excellence.