API RP 578 provides guidelines for material verification programs to ensure alloy components used in new and existing process piping systems match the specified materials. It covers ferrous and nonferrous alloys used in piping covered by ASME B31.3 and API 570 standards. The RP specifies that the owner/user should establish a written material verification program outlining the extent and type of positive material identification testing during construction, maintenance, and inspection. It provides guidance on roles and responsibilities for material verification programs and recommends higher examination levels for higher-risk systems to better detect any incorrect material substitutions.

![Charlie Chong/ Fion Zhang/ He Jungang / Li Xueliang

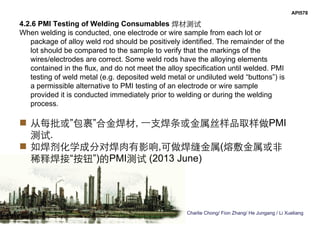

API578

5.2.5.2 Resistivity Testing 电阻率的测试

The principle employed in the test method is known as the Seebeck Effect, or

thermoelectric principle. A heated junction of dissimilar metal is created when the

heated probe [300oF (150oC)] and the metal being tested are in contact with each

other. The voltage generated at this junction is representative of the chemistry

and crystalline structure of the metal being tested. Every alloy of a given

crystalline structure will generate the same voltage regardless of the geometry or

size of the piece being tested or the pressure applied. By references to known

standards, these instruments are capable of sorting and identifying a wide range

of ferrous and nonferrous materials. Alloy sorters have not proved to be

consistently capable of sorting low alloy (< 5 % Cr) and austenitic stainless steels.](https://image.slidesharecdn.com/api578-140604185143-phpapp01-160706204222/85/Api-578-86-320.jpg)