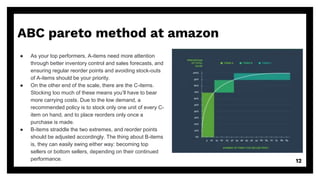

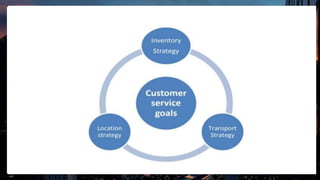

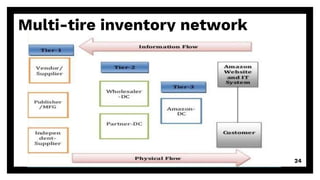

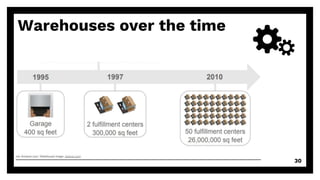

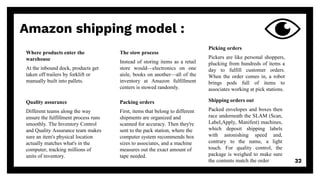

Amazon started as an online bookstore in 1994 and has since diversified its product offerings. It operates without retail stores and relies solely on e-commerce. To manage its vast inventory, Amazon uses techniques like ABC analysis to categorize products, just-in-time delivery to receive goods as needed, and outsourcing storage of less popular items. However, it has moved away from extensive outsourcing to focus more on its own fulfillment centers to improve customer service and reduce stockouts. Amazon's inventory management has evolved over time through increasing automation in warehouses, using a multi-tiered network of facilities, and adopting strategies like location postponement.