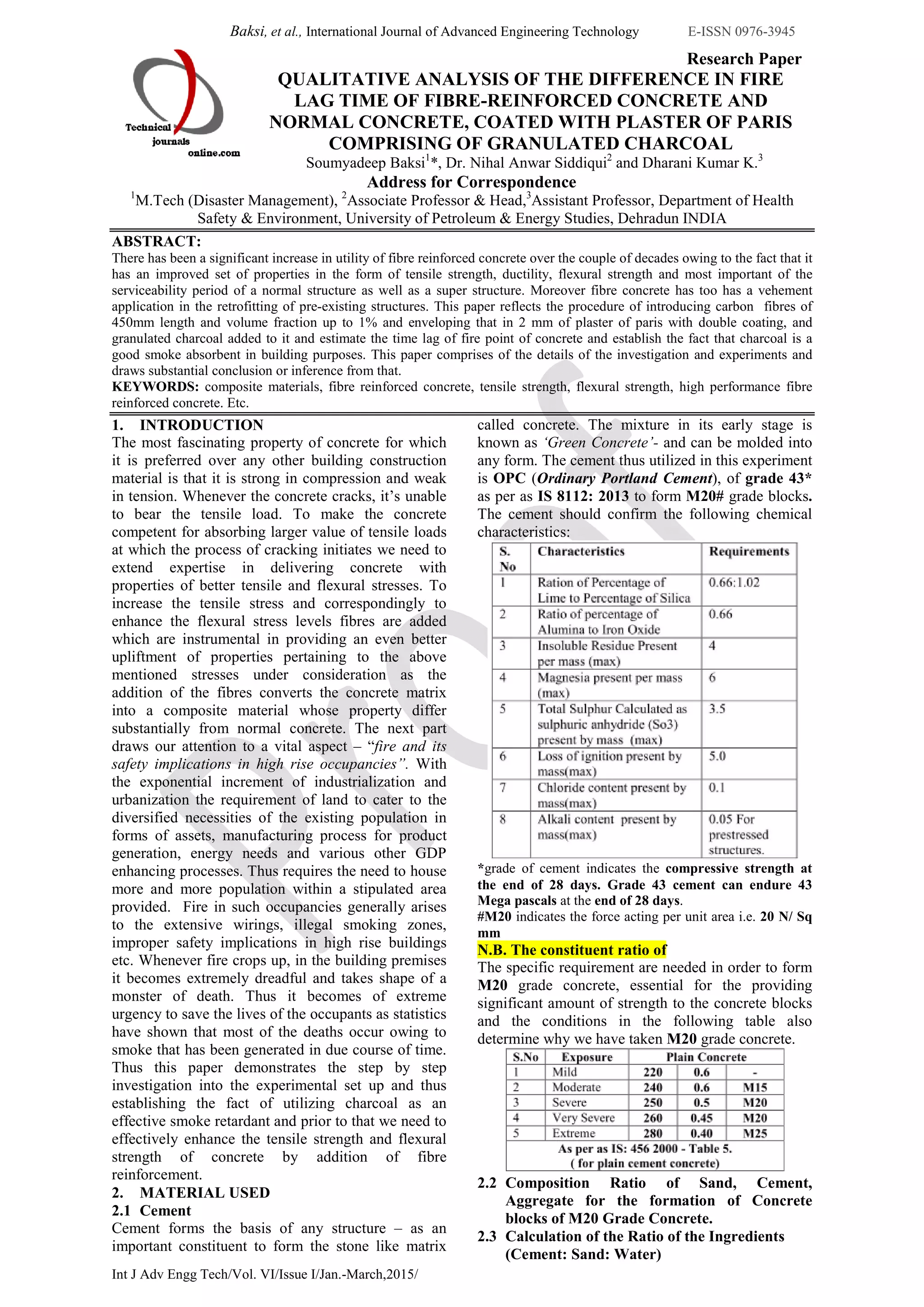

This document summarizes a study that analyzed the difference in fire lag time between normal concrete blocks and glass fibre reinforced concrete blocks coated with plaster of paris containing granulated charcoal. The researchers created concrete blocks, coated one with plaster of paris and granulated charcoal, and subjected both to an oxyacetylene flame. They found the fire lag time of the coated block was 16.75% longer than the normal concrete block, indicating the plaster of paris and charcoal coating helped maintain strength and increase fire resistance time. The document provides details on the materials, testing methods, and conclusions of the study.