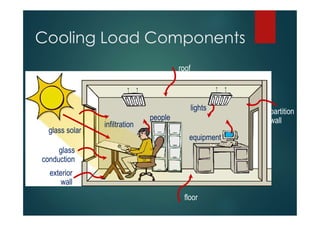

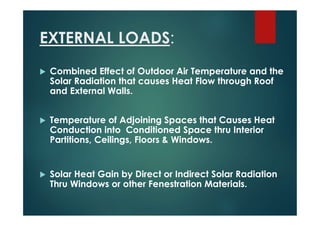

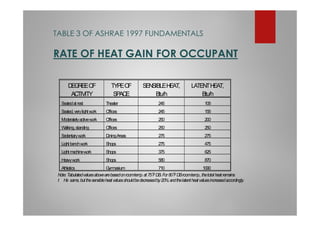

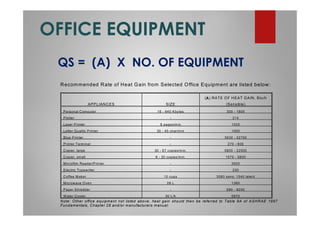

The document outlines the principles and procedures for calculating air conditioning loads in various building types. It explains methods of heat transfer, definitions of key terms like BTU, and factors affecting human comfort. Additionally, it covers types of heat gain and detailed procedures for load calculation, which include data gathering, analysis of heat transfer coefficients, and psychrometric analysis.

![Measuring Heat Quantity

60°F 61°F

15°C 16°C

1 Btu

1 kcal

[4.19 kJ]

1 lb

Water

1 kg

Water](https://image.slidesharecdn.com/airconditioningloadcalculationpresentation-15-09-2017-240716175028-8560d4eb/85/Air-Conditioning-Load-Calculation-Presentation-15-09-2017-pdf-6-320.jpg)

![Indoor Design Conditions

Dry-bulb Temperature

Humidity

Ratio

80°F

[26.7°C]

80°F

[26.7°C]

70°F

[21.2°C]

70°F

[21.2°C]

comfort zone

A

A](https://image.slidesharecdn.com/airconditioningloadcalculationpresentation-15-09-2017-240716175028-8560d4eb/85/Air-Conditioning-Load-Calculation-Presentation-15-09-2017-pdf-10-320.jpg)

![Sensible Vs Latent Heat

60°F

[15.6°C]

212°F

[100°C]

212°F

[100°C]

212°F

[100°C]

Sensible Heat

Latent Heat](https://image.slidesharecdn.com/airconditioningloadcalculationpresentation-15-09-2017-240716175028-8560d4eb/85/Air-Conditioning-Load-Calculation-Presentation-15-09-2017-pdf-16-320.jpg)