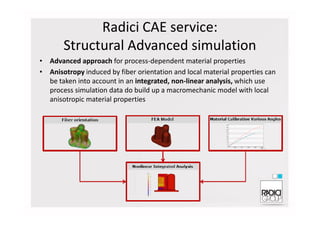

The document summarizes Radici Group's press conference on advances in innovation. Some key points:

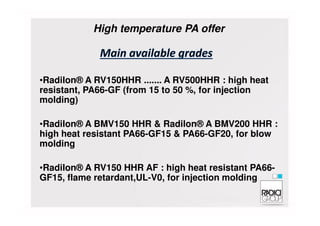

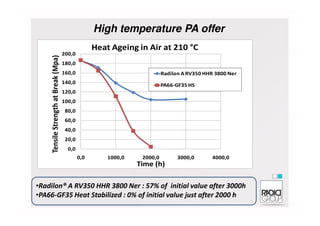

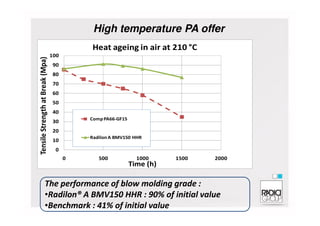

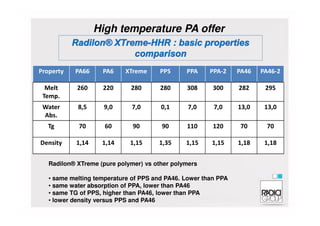

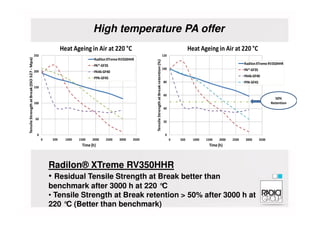

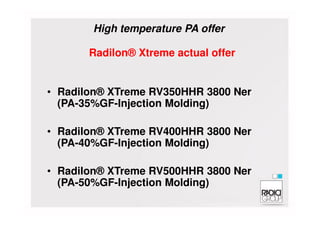

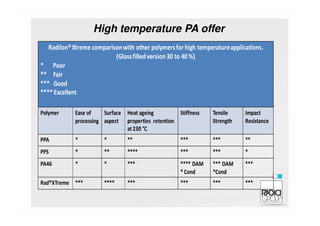

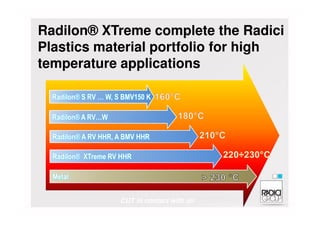

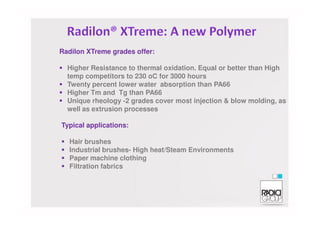

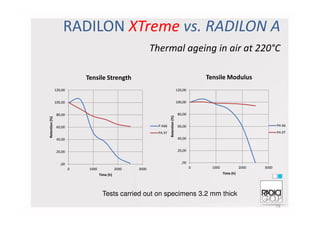

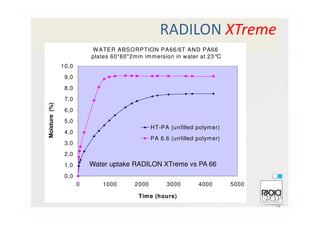

- Radici Group introduced their new high heat resistant and high temperature polyamides under the Radilon® brand, including Radilon® Xtreme grades for applications up to 230°C.

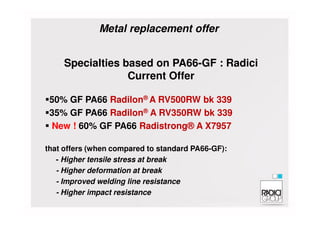

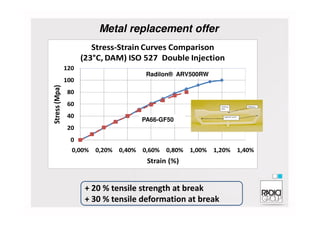

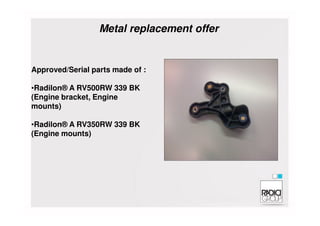

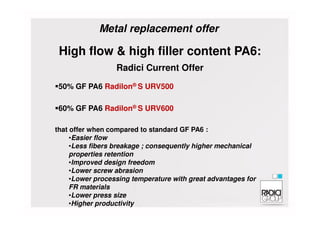

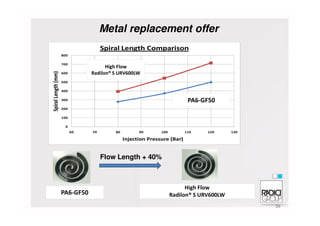

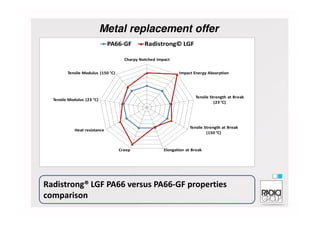

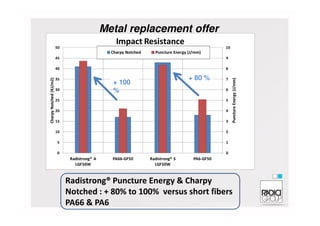

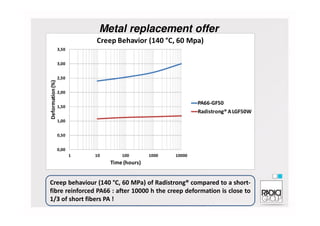

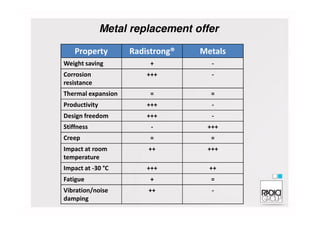

- They presented their metal replacement portfolio focused on long glass fiber reinforced polyamides like Radistrong® A X7957 with 60% GF for higher strength and tougher applications.

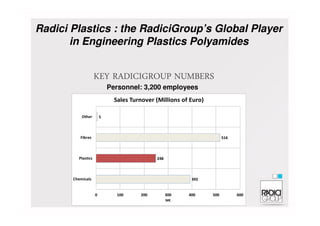

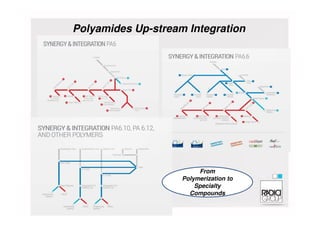

- Radici also discussed their global manufacturing footprint and wide range of engineered plastics brands for applications in automotive, electronics, consumer and industrial sectors.