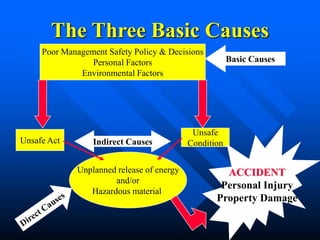

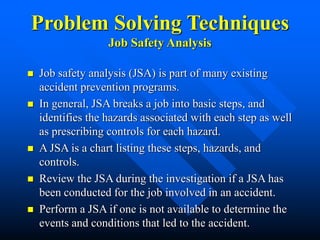

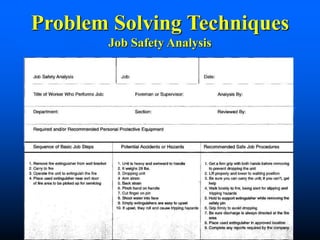

This document provides guidance on conducting accident investigations. It defines an accident and explains that most are caused by failures of people, equipment, supplies or surroundings. An investigation determines the direct and indirect causes of an accident to identify corrective actions and prevent future accidents. The investigator should document the accident scene, interview witnesses, analyze the work being done and report findings with recommendations. Conducting a thorough investigation is important to understand what happened and why in order to implement solutions that prevent similar accidents.