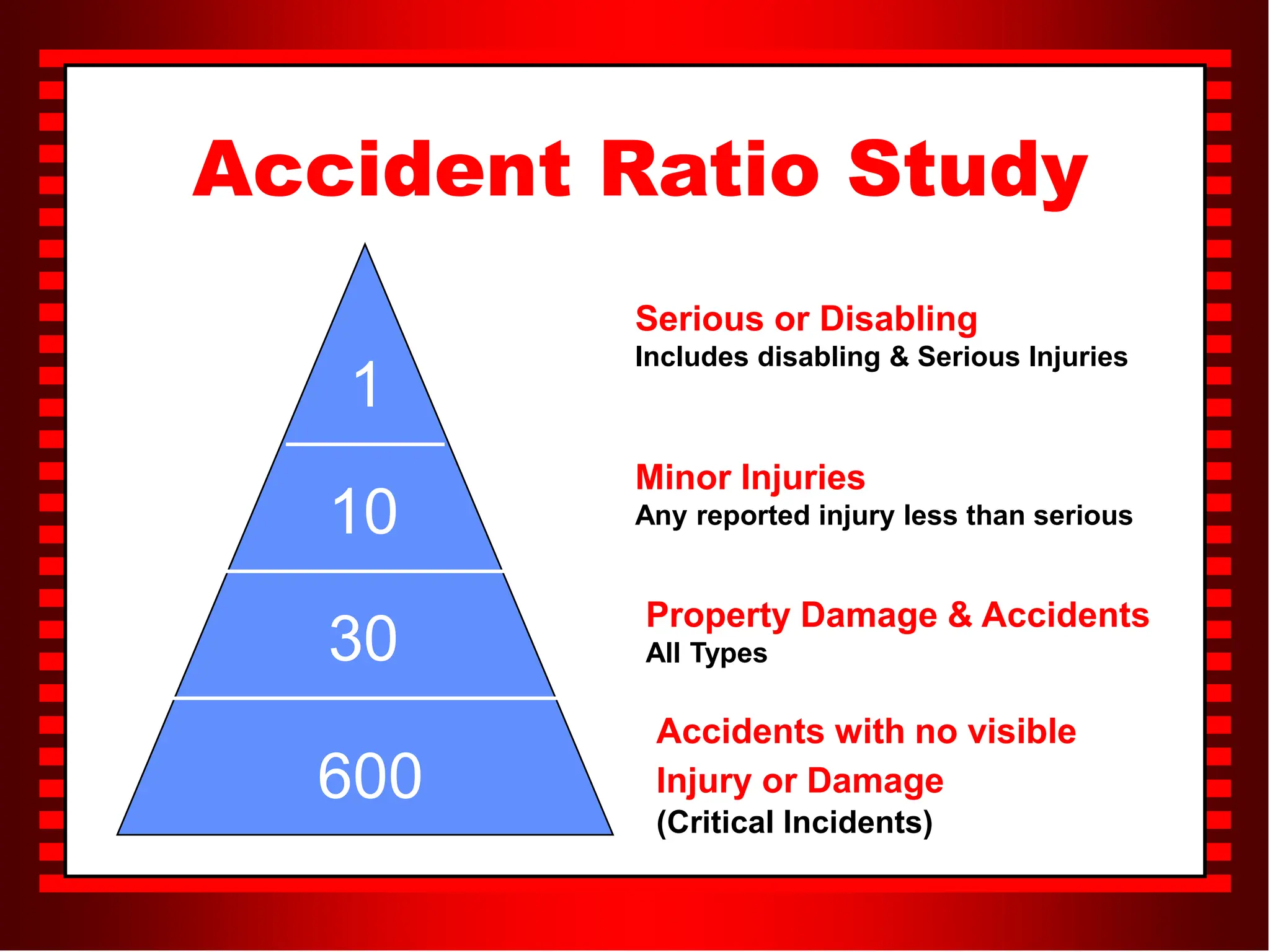

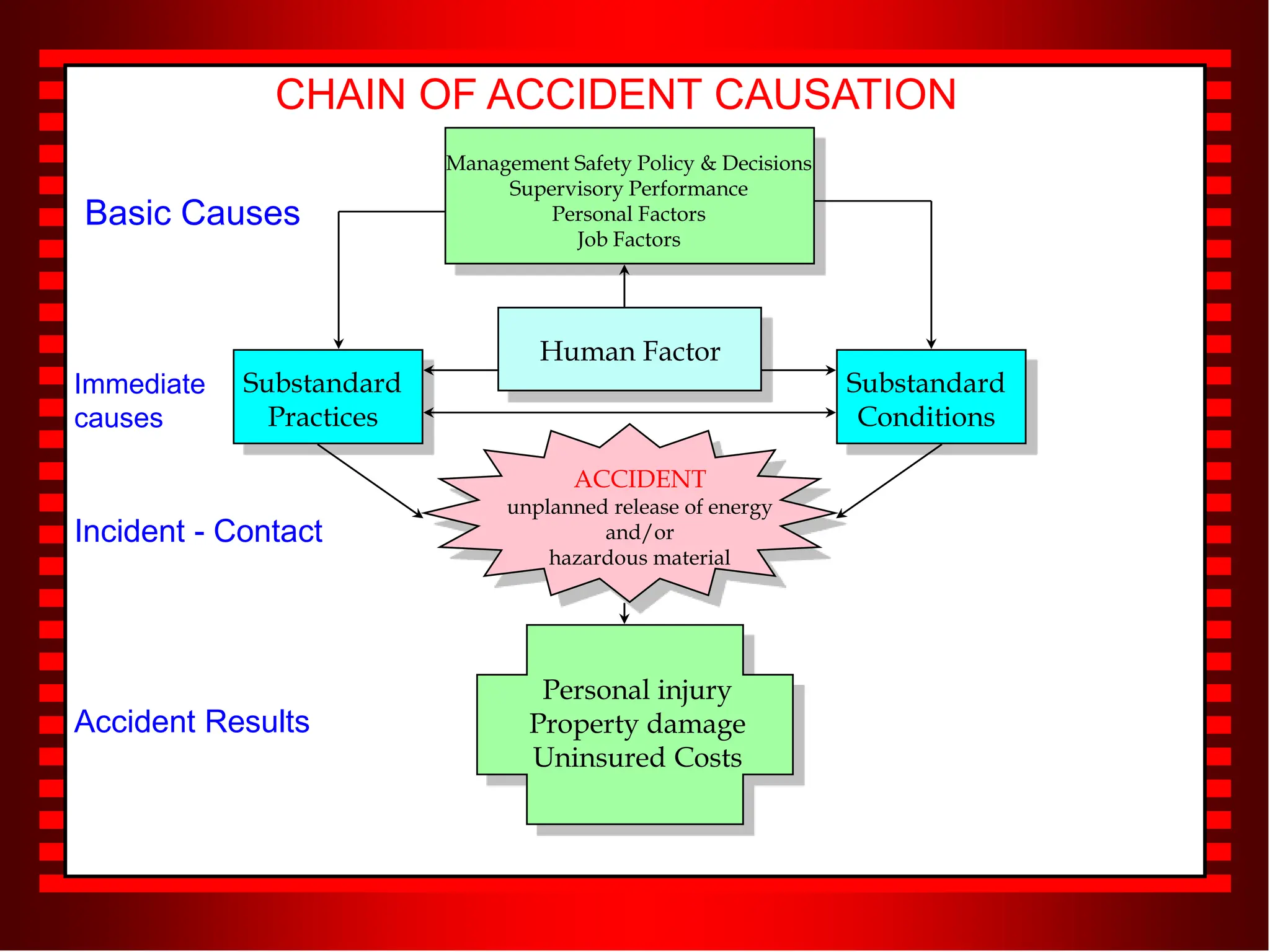

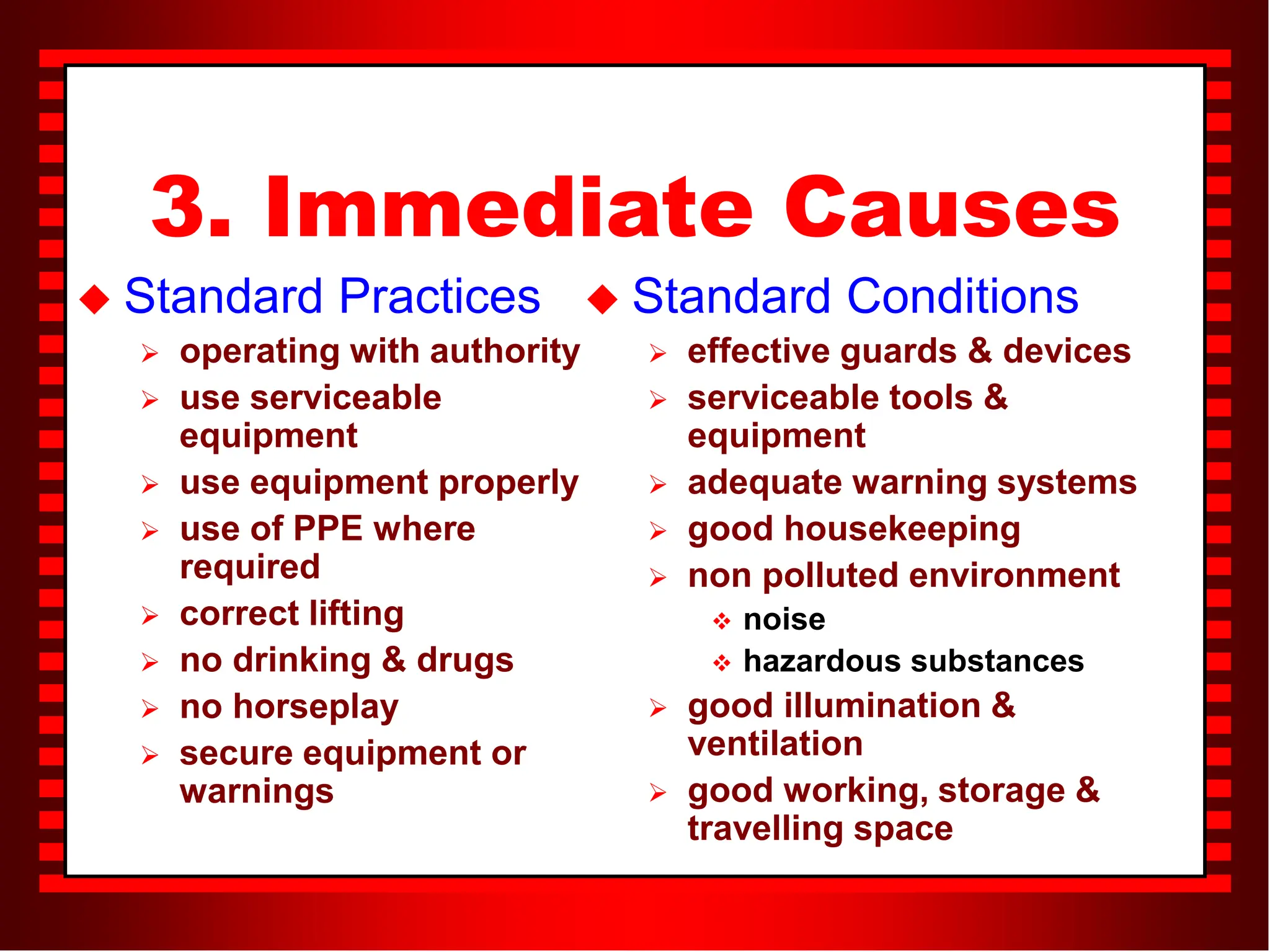

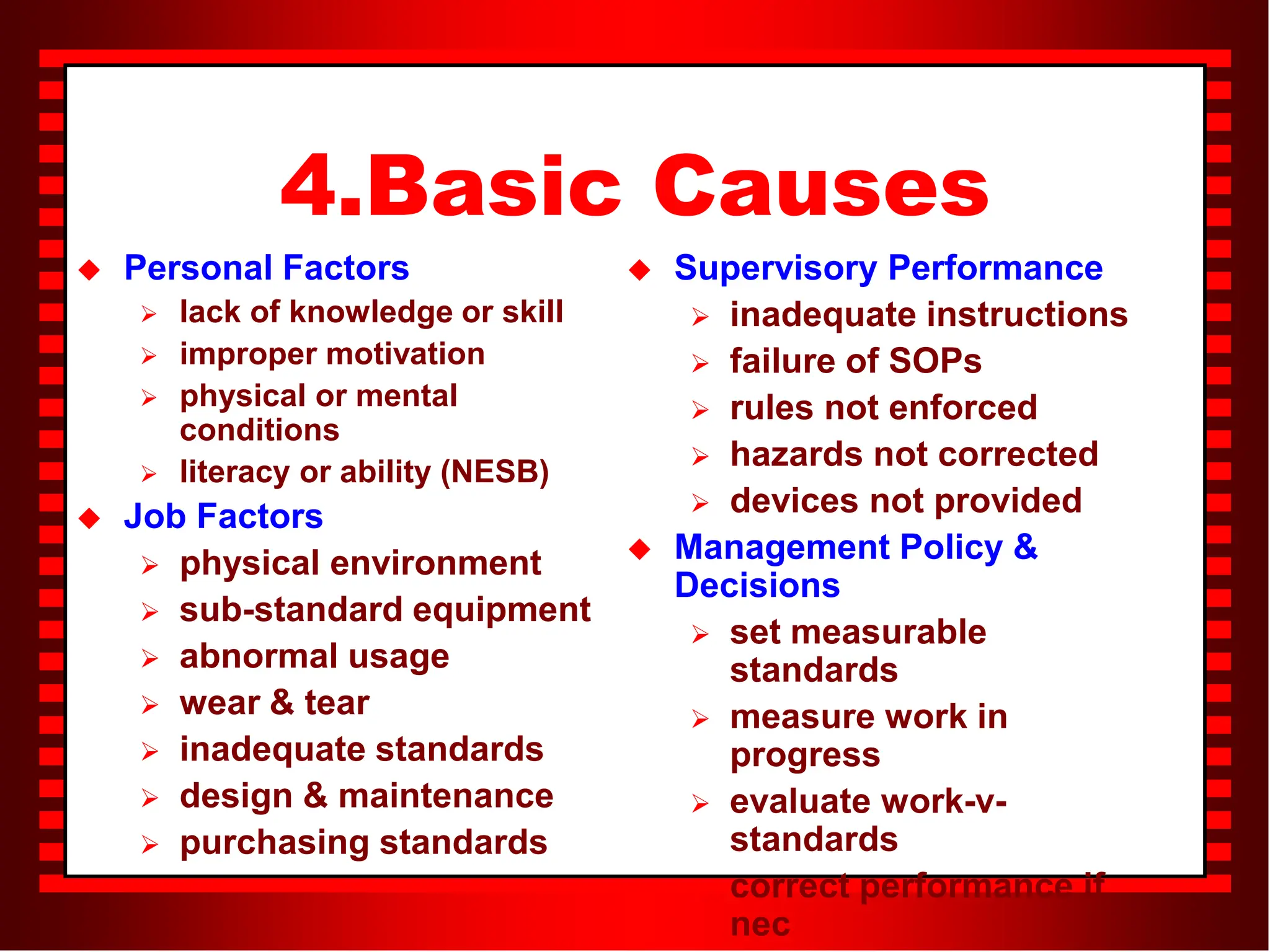

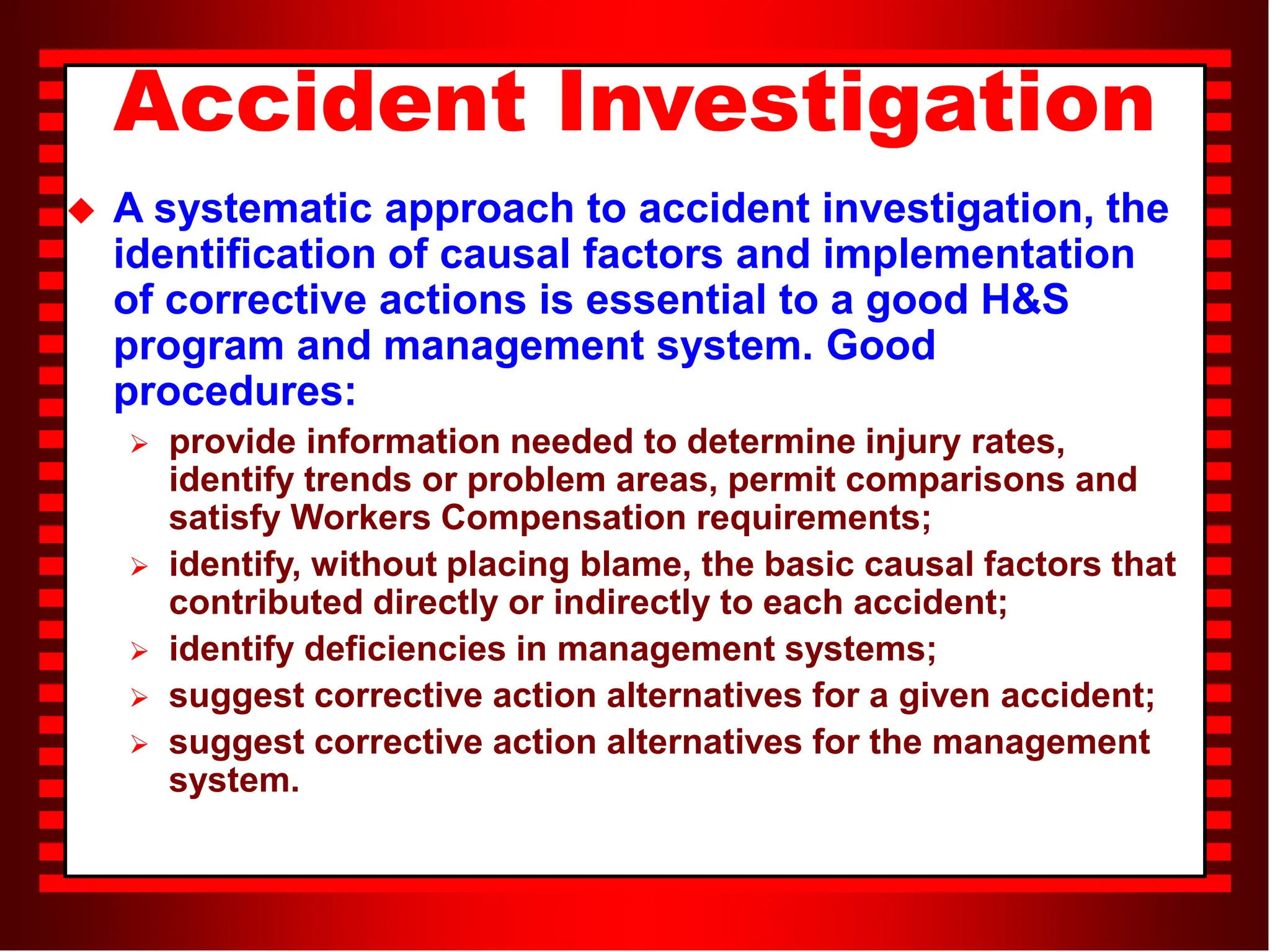

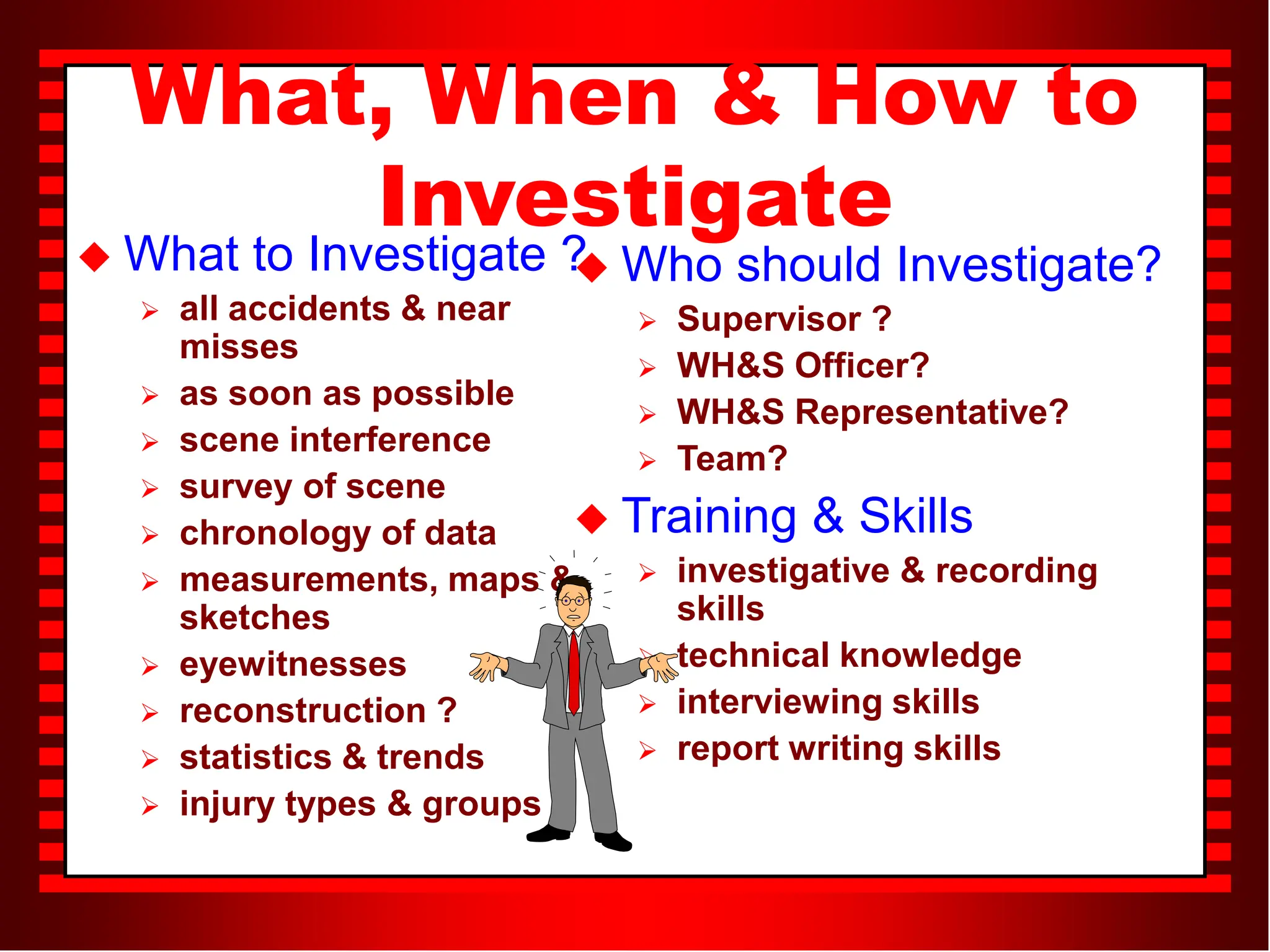

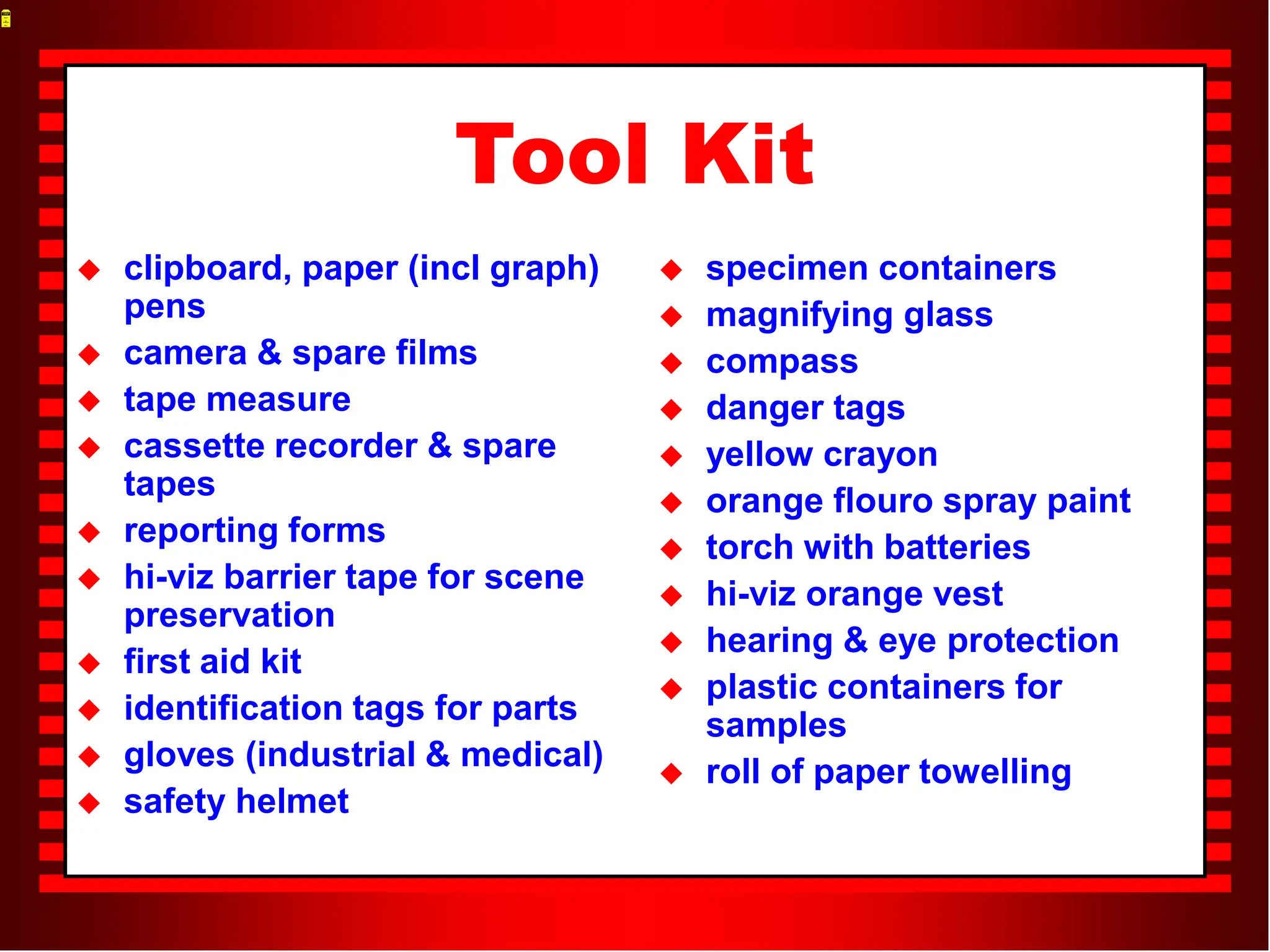

The document outlines the objectives and methodologies for accident and incident prevention and investigation, emphasizing the importance of understanding causes, thorough investigation, and safety protocols. It defines accidents, near misses, and various causal factors, and it provides a systematic approach for investigating and documenting incidents to enhance safety management systems. Additionally, it highlights the consequences of accidents on individuals, supervisors, companies, and society, underscoring the need for effective accident prevention strategies and resources.