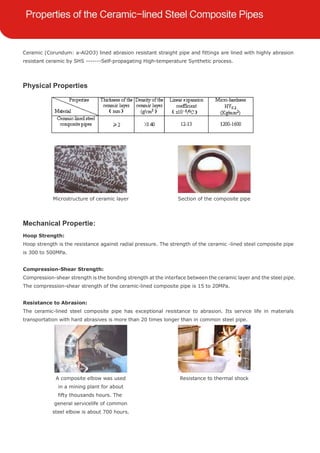

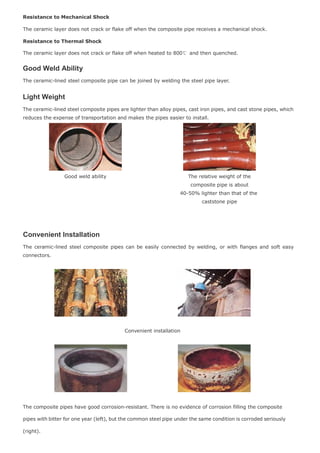

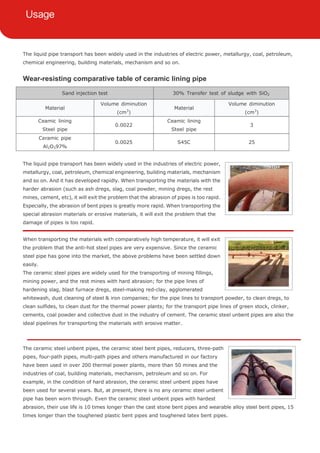

The document describes the properties and applications of abrasion-resistant ceramic lined steel pipes manufactured through a self-propagating high-temperature synthetic process. These composite pipes exhibit exceptional abrasion and corrosion resistance, lightweight characteristics, and a service life significantly longer than traditional pipes, making them ideal for transporting materials in various industrial sectors. Additionally, their production method allows for cost improvements and reduced maintenance compared to conventional materials.