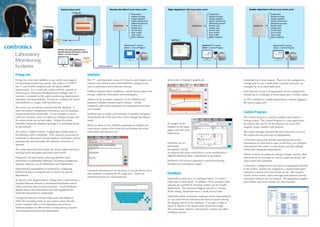

Prolog Lite is an environmental monitoring system from Contronics Limited that monitors up to 100 sensor points across multiple sites. It consists of a central Prolog Lite server and InfoPoint display, networked via Ethernet to remote DataNodes that collect sensor data. The system provides real-time alarm notifications, historical data logging, and role-based access via the Control Program. Users can configure sensors, set alarm thresholds, and accept alarms from any networked PC.