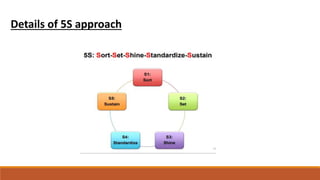

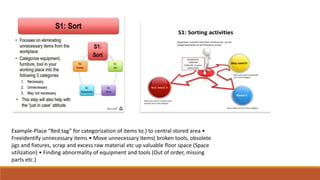

5S is a workplace organization method that involves sorting, setting in order, shining, standardizing and sustaining. It aims to establish good working practices through reducing muri, mura and muda, which refer to overburden, inconsistency and waste. The 5S approach originated in Japanese manufacturing in the 1980s as part of the Toyota Production System. It involves activities like identifying unnecessary items, reorganizing the workspace, cleaning equipment and tools, and establishing standards and processes to maintain the new systems. Regular audits are carried out to ensure continued compliance.