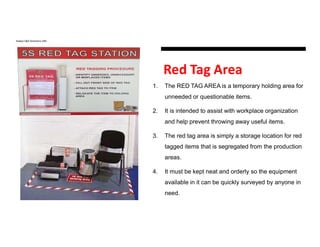

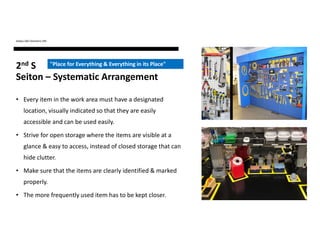

The document provides a comprehensive overview of the 5S workplace organization methodology, which includes five steps: sort, set in order, shine, standardize, and sustain. It highlights the importance of these steps in improving workplace efficiency, safety, and morale, while providing techniques for properly implementing them. Additionally, it discusses the red tag process for managing unneeded items and emphasizes the need for discipline in adhering to established standards.