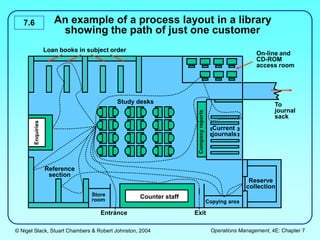

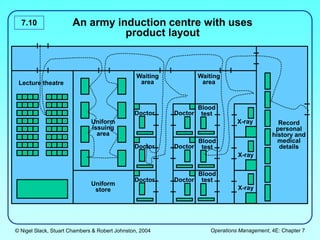

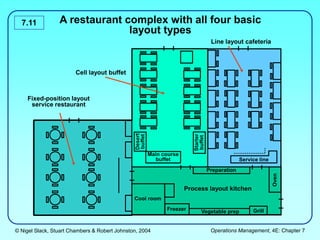

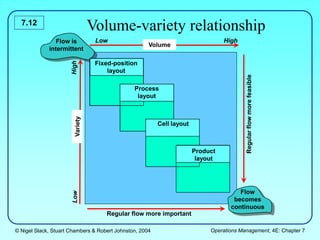

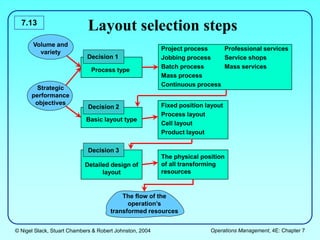

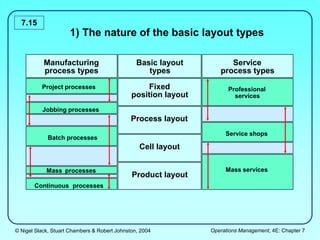

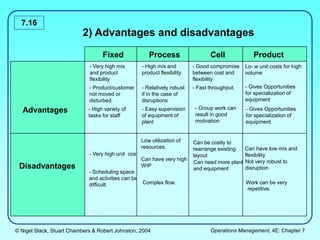

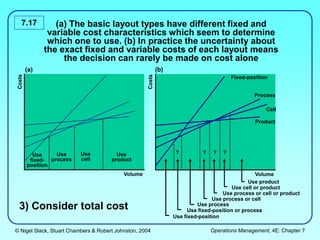

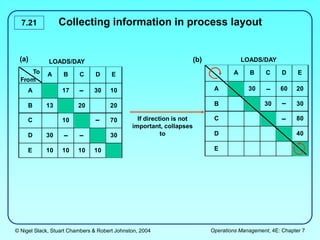

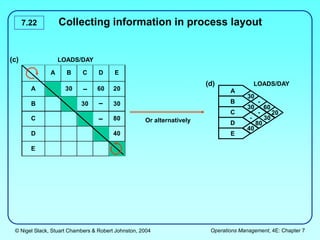

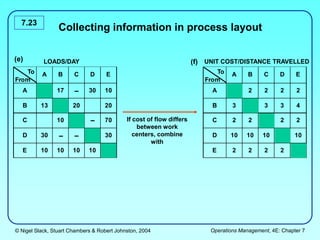

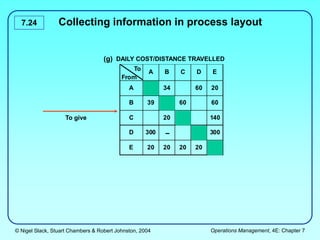

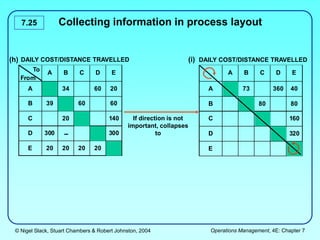

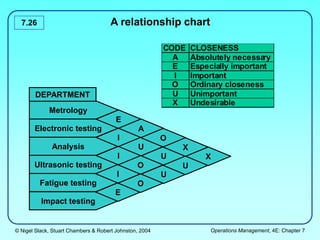

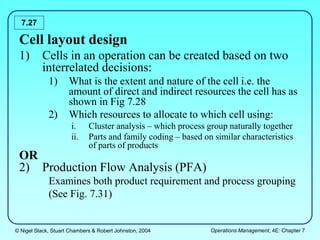

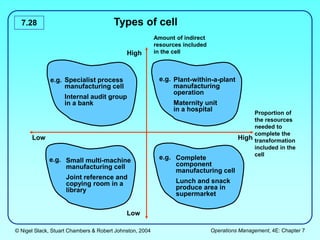

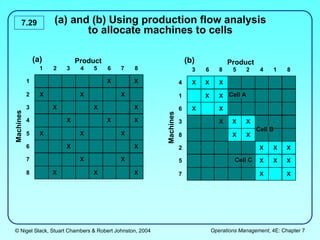

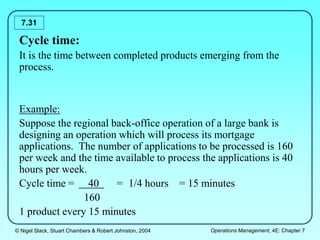

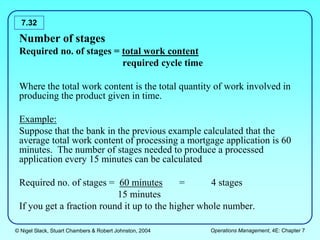

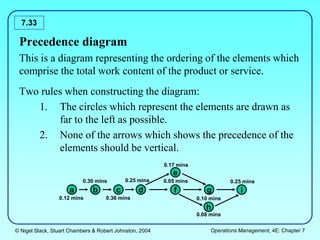

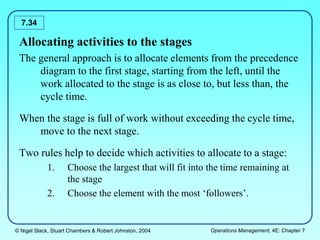

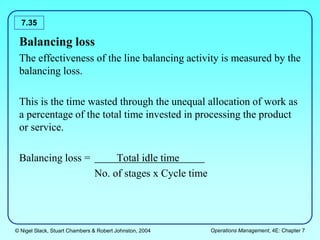

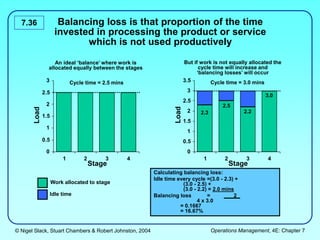

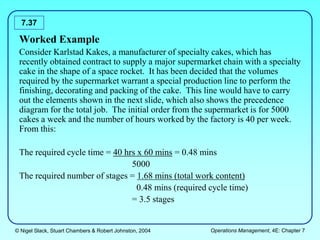

Chapter 7 of 'Operations Management' covers various layout types in operations management, including fixed position, process, cell, and product layouts. Each layout type has unique characteristics, advantages, and disadvantages, influencing the choice based on factors such as production volume and variety. The chapter also discusses the design and optimization of layouts to enhance operational efficiency.