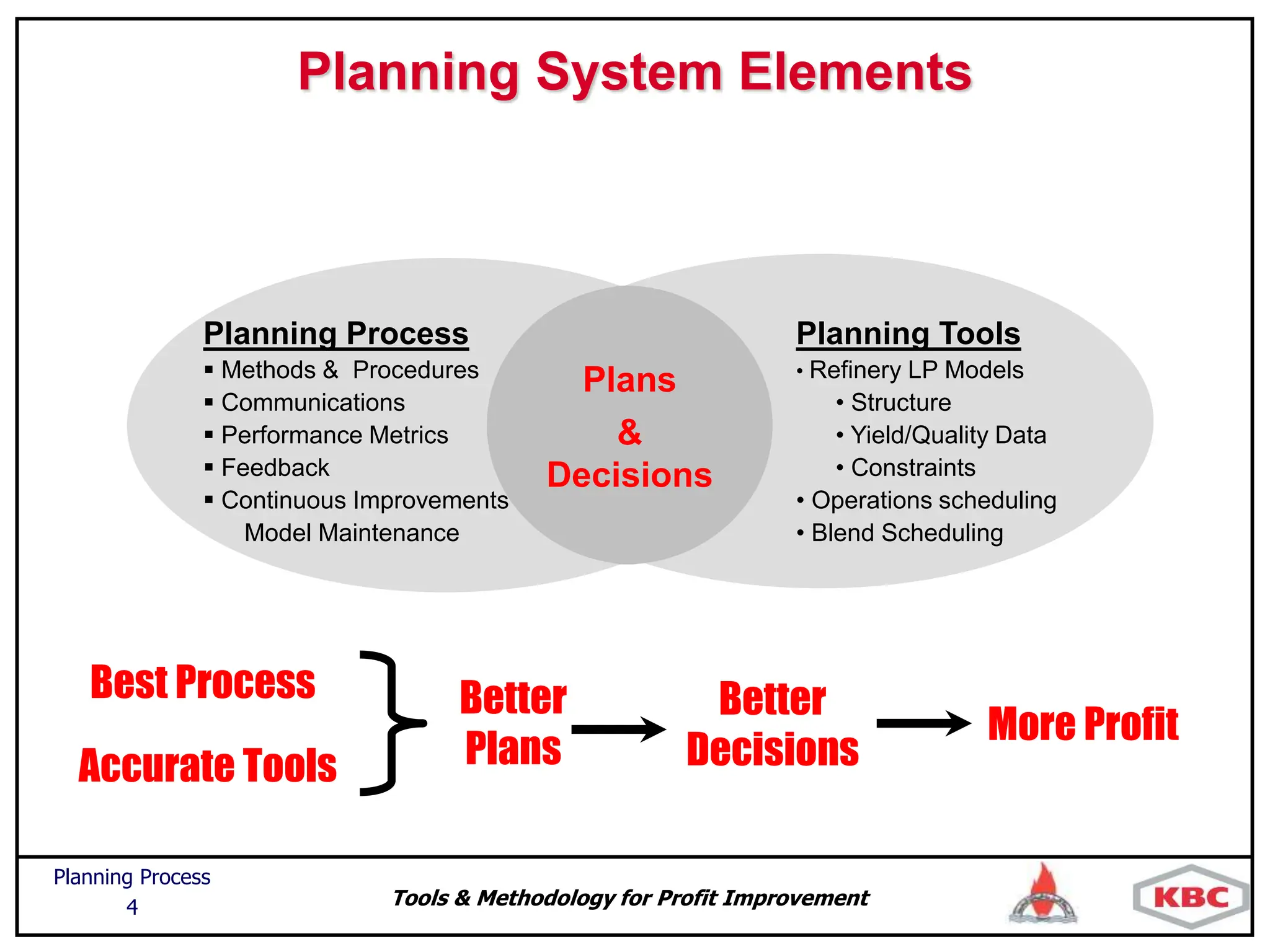

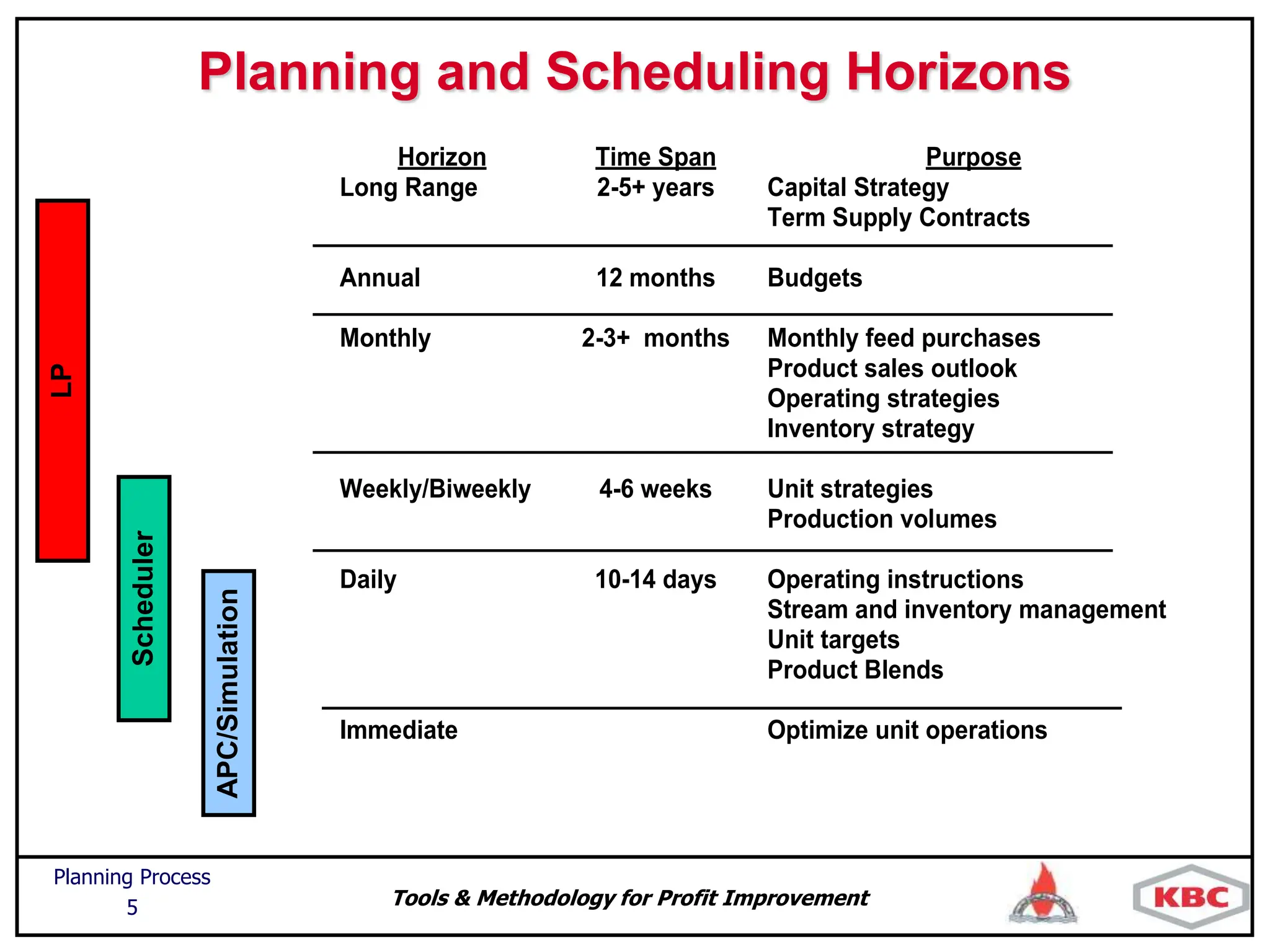

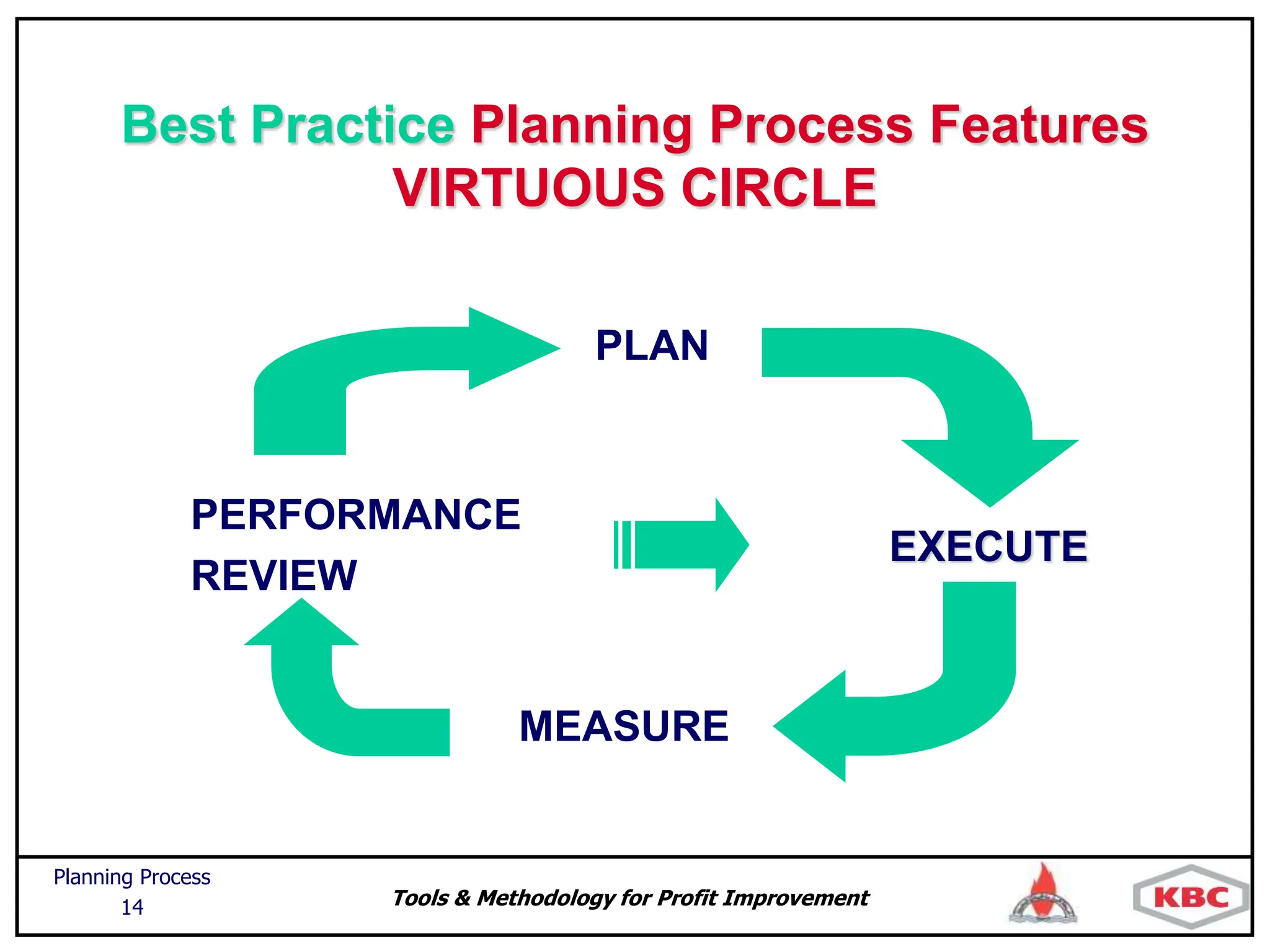

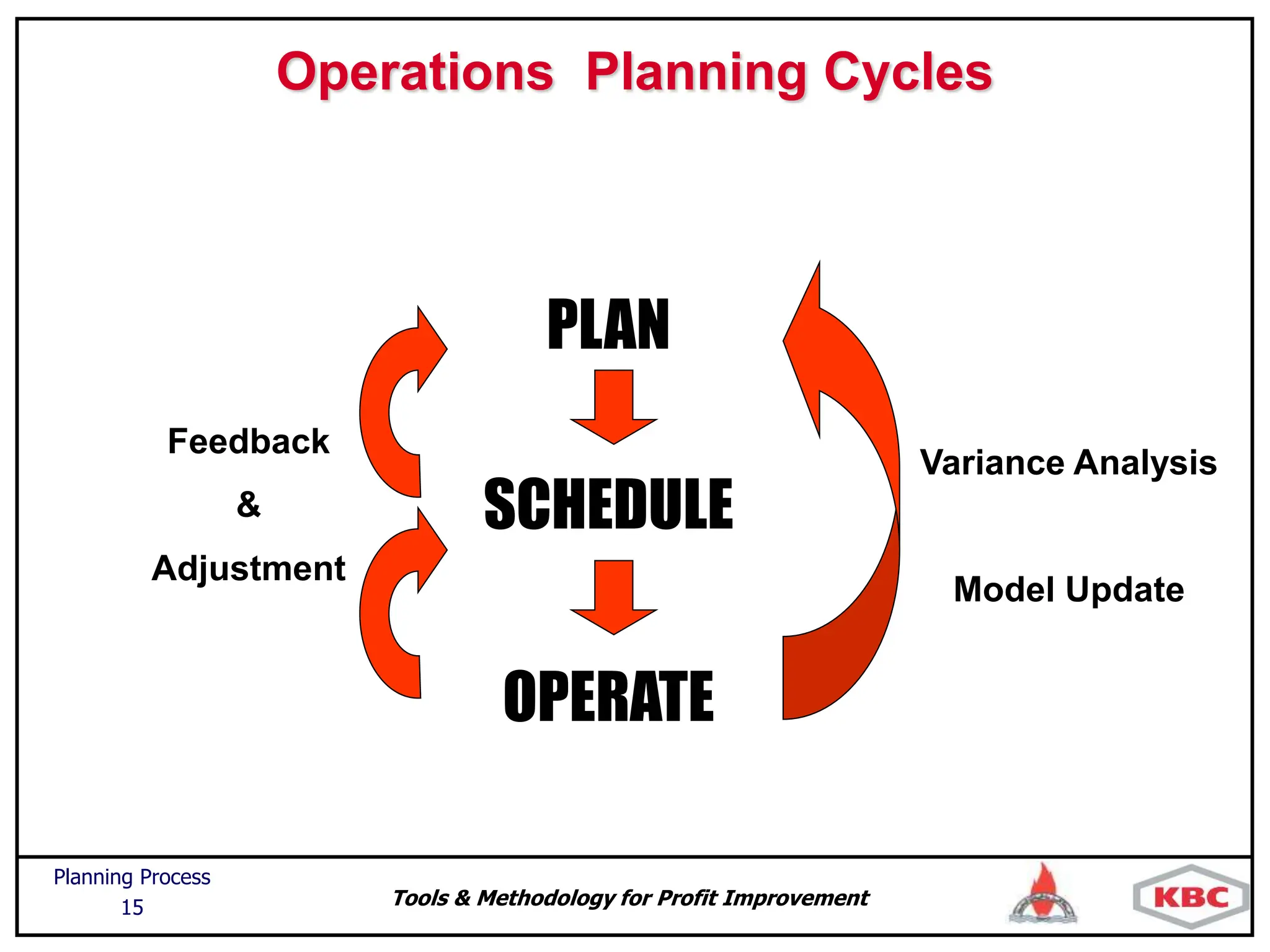

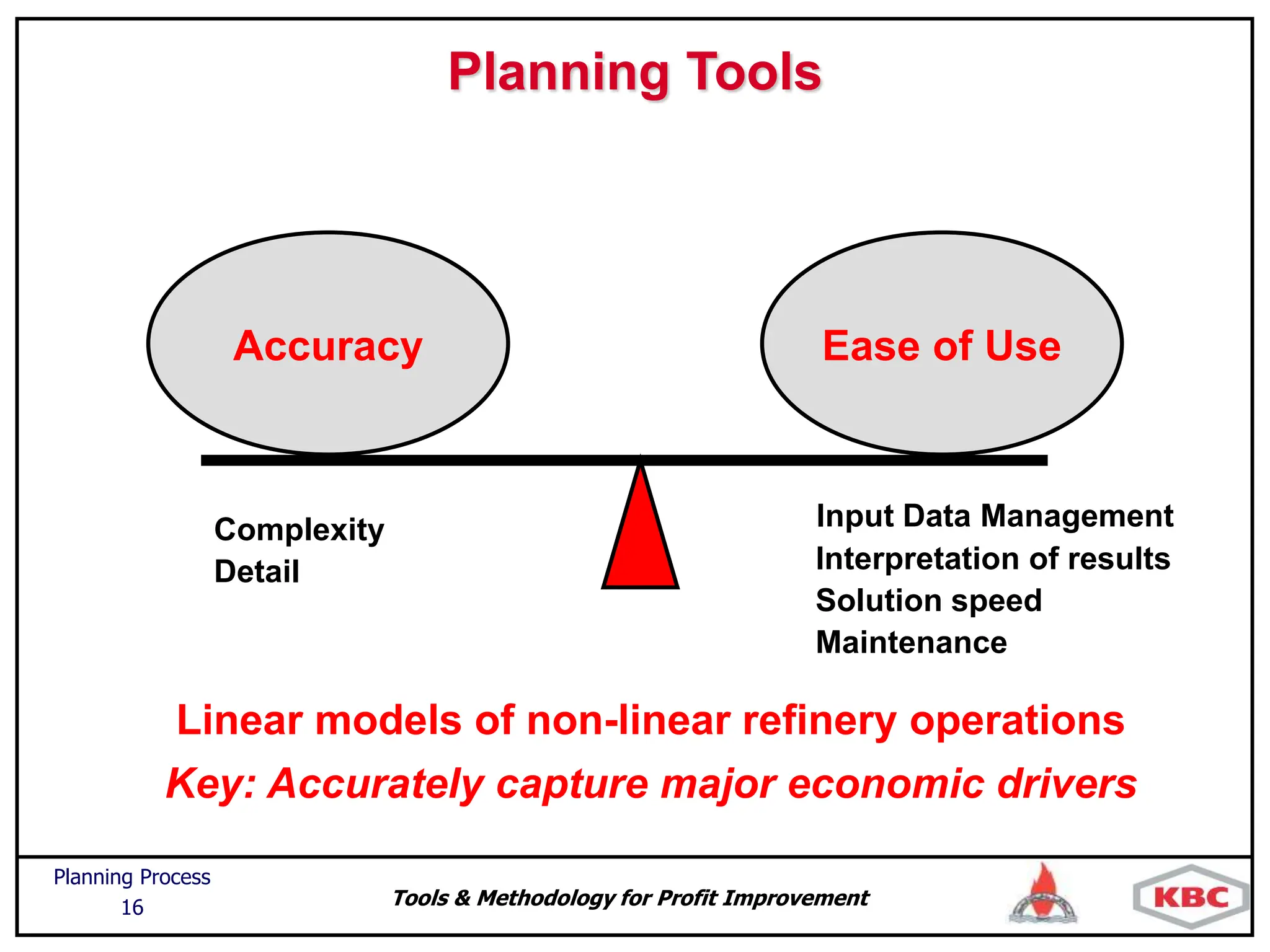

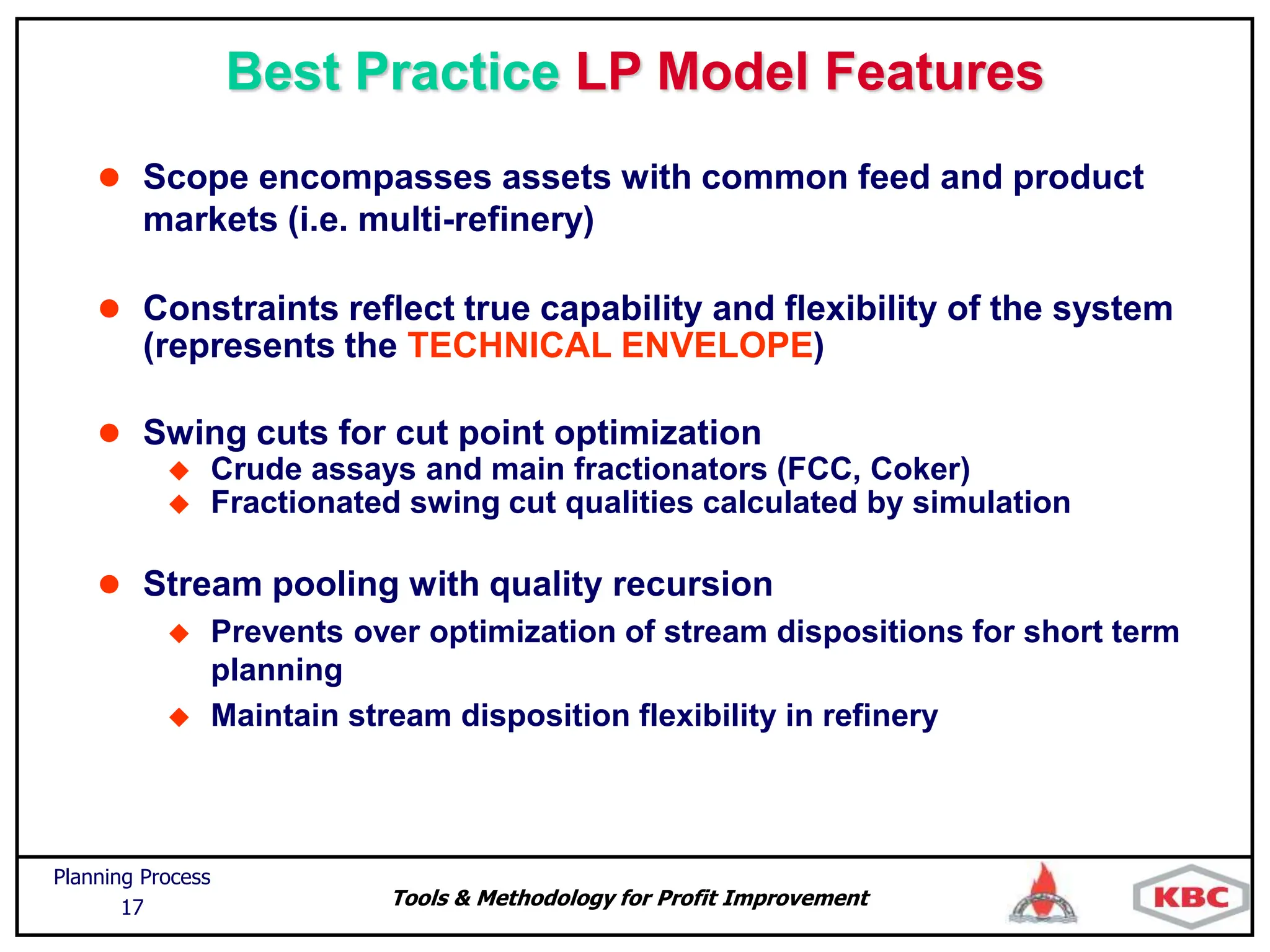

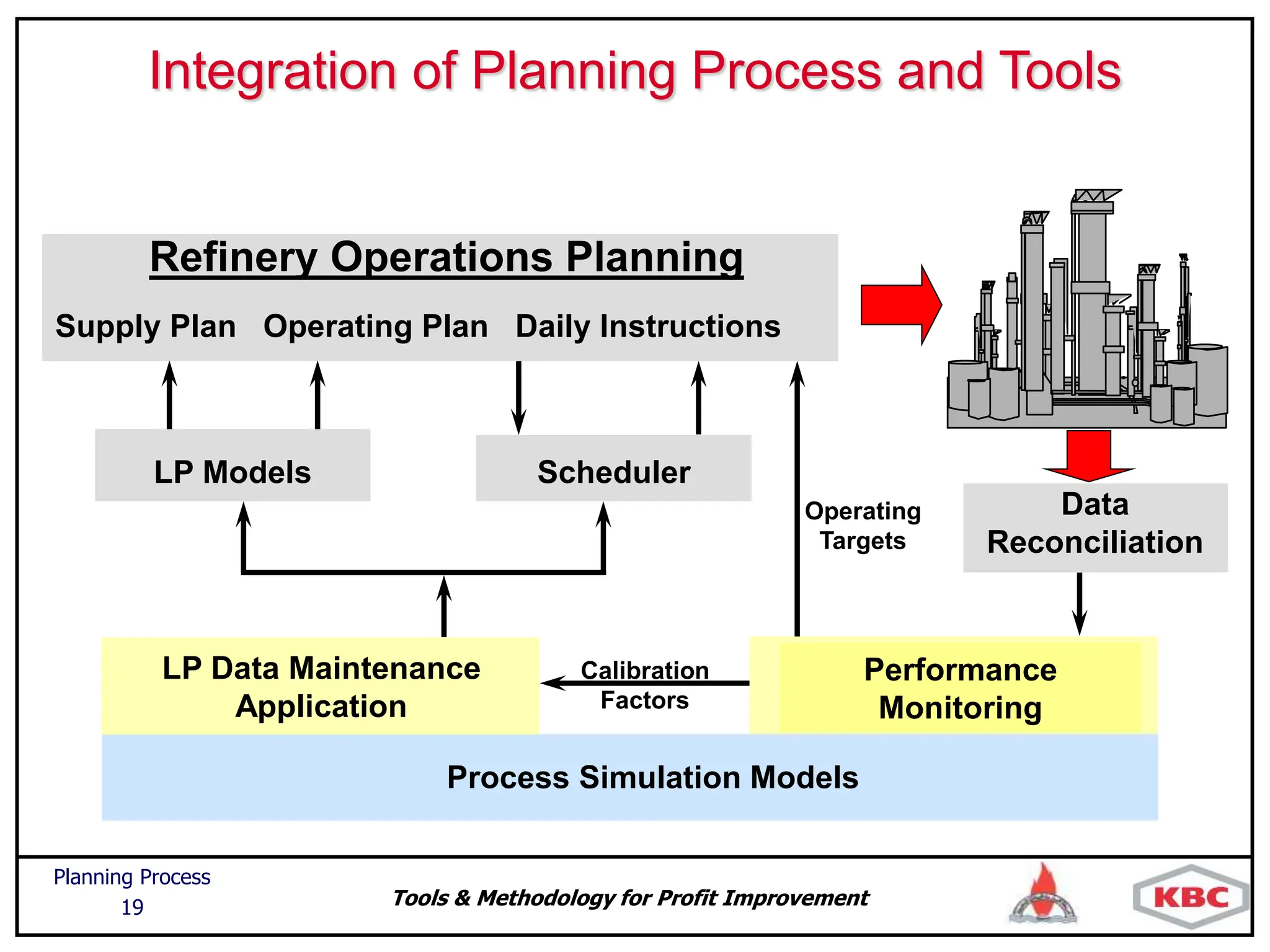

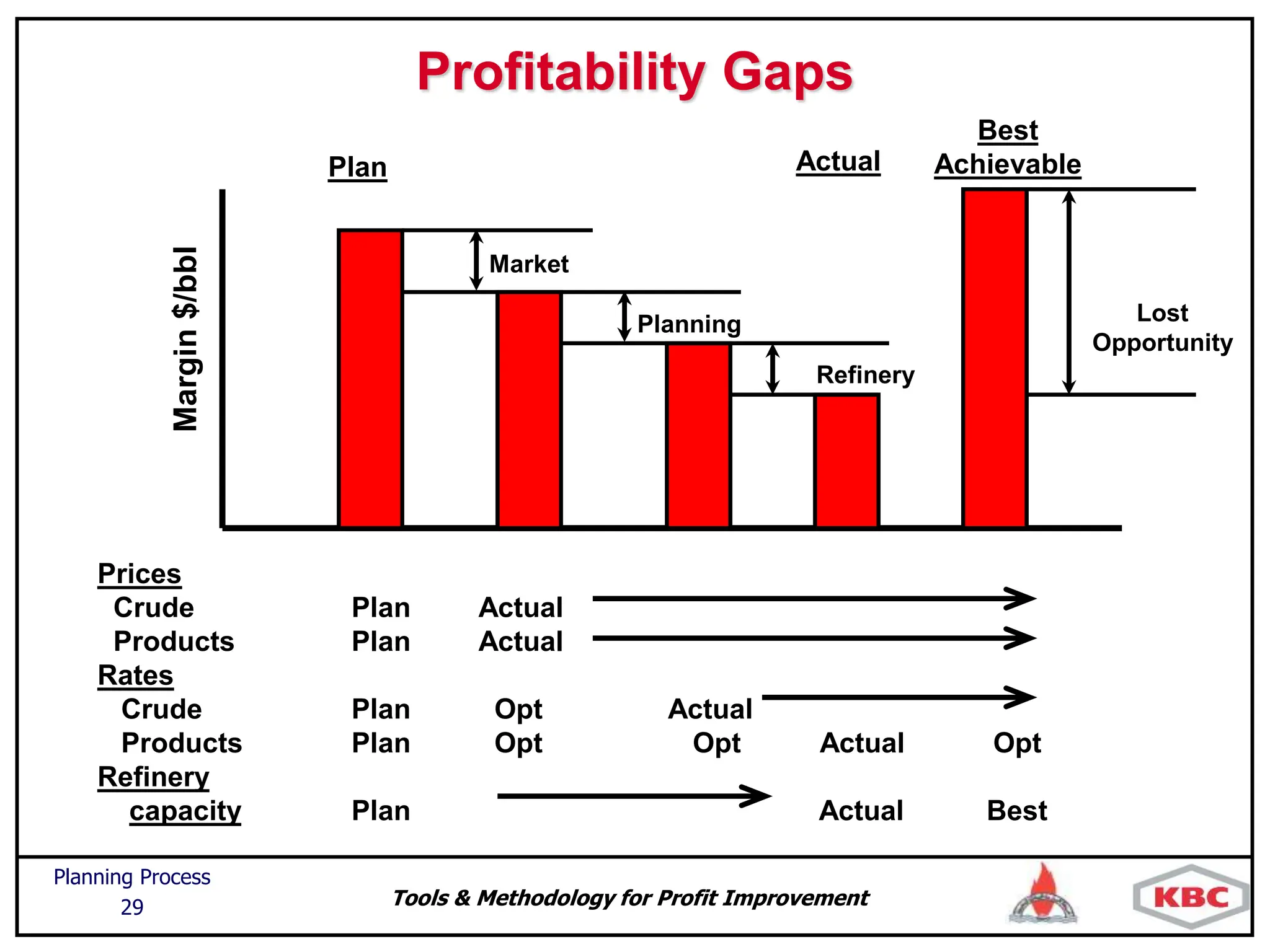

This document discusses best practices for refinery planning processes and tools. It recommends that planning processes involve multi-refinery linear programming models, accurate representation of unit operations, and clear communication between planning and operations teams. Regular performance reviews should use backcasting to understand profit deviations and ensure continuous improvement. The goal is for refineries to operate according to the optimal plan defined by the linear programming model.