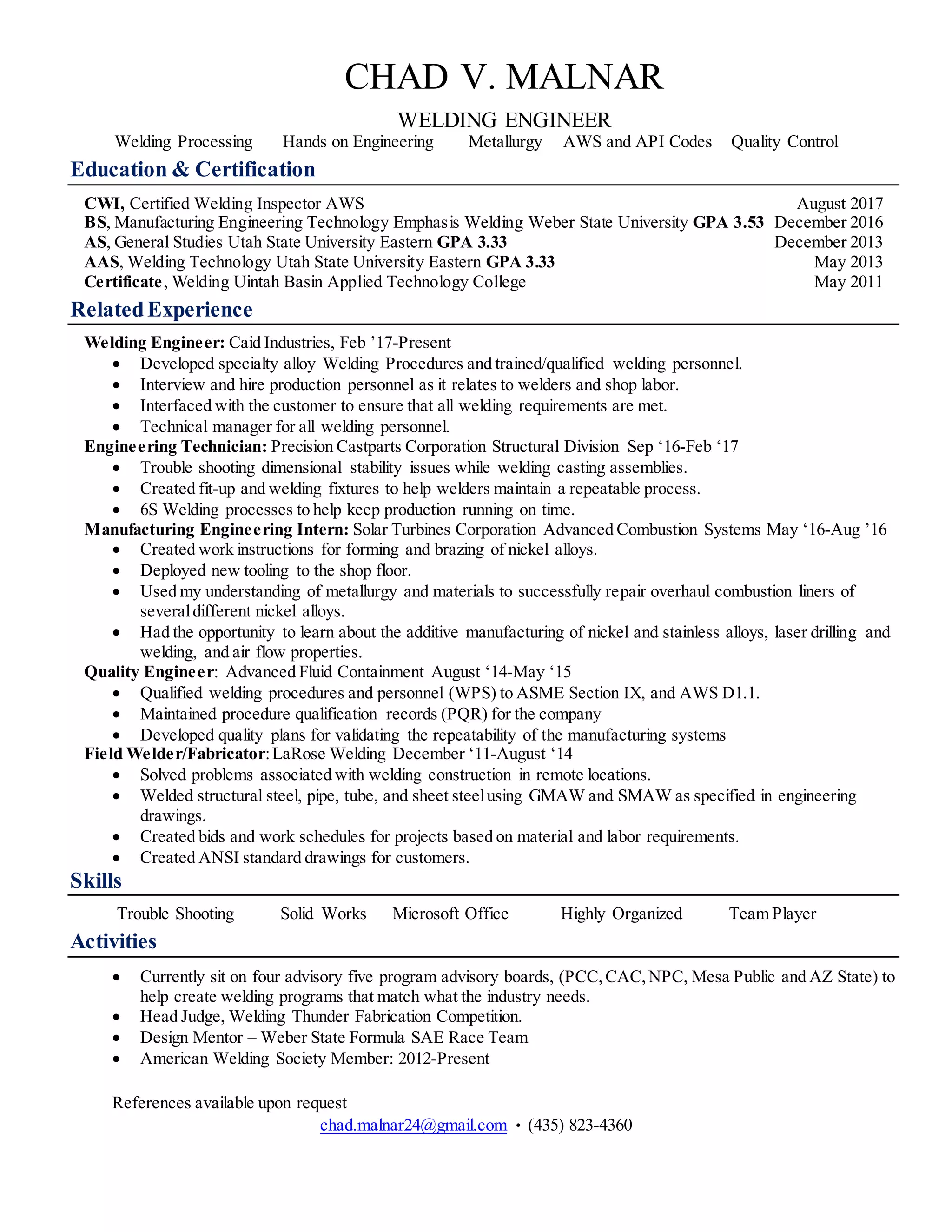

Chad Malnar is a welding engineer with experience developing welding procedures, training welding personnel, and ensuring customer requirements are met. He has a BS in Manufacturing Engineering Technology with an emphasis in welding and is a Certified Welding Inspector. His career has included roles as an engineering technician, manufacturing engineering intern, quality engineer, and field welder/fabricator. He has strong skills in troubleshooting, SolidWorks, quality control, and meeting ASME and AWS standards.