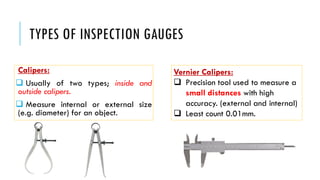

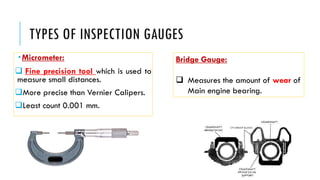

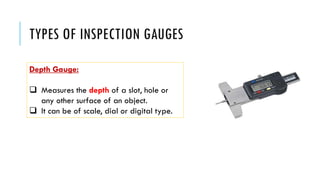

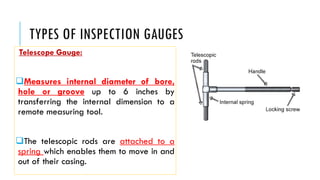

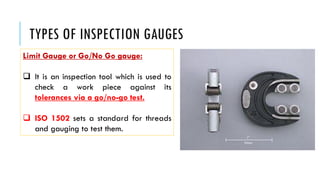

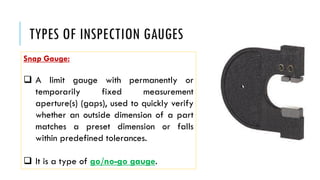

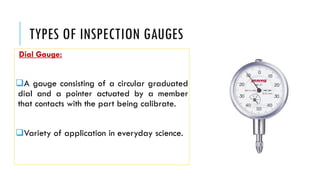

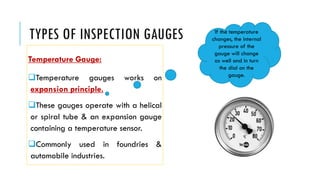

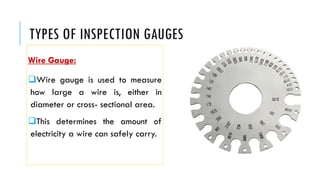

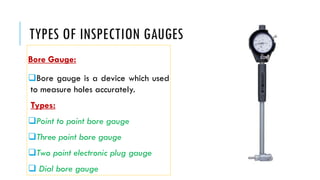

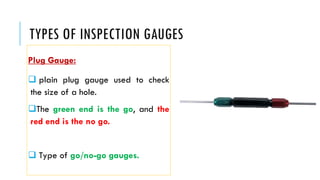

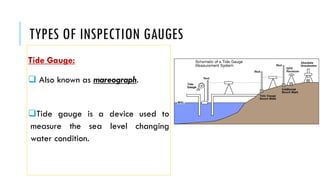

This document discusses different types of inspection gauges used to measure physical quantities in manufacturing. It defines a gauge as a device that measures physical quantities like thickness, gap, diameter, pressure, or flow along a calibrated scale. Some common gauges mentioned include calipers, vernier calipers, micrometers, bridge gauges, depth gauges, dial gauges, thread pitch gauges, feeler gauges, bore gauges, and plug gauges. The document provides details on each type of gauge, including what they measure and their applications in quality inspection.