1. The document summarizes Vinoth Kumar's research progress meeting at the National Institute of Technology Puducherry on dissimilar metal welding.

2. Vinoth is researching welding of dissimilar metals under the supervision of Dr. A. Karpagaraj. His broad research area is welding and he is pursuing his studies full time with an institute fellowship.

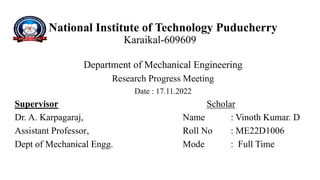

3. The document provides details of Vinoth's coursework, doctoral committee members, challenges of dissimilar metal welding like formation of brittle phases and residual stresses, and weldability of different materials.

![Relative Properties of Different Materials

• [Ref - Edison welding institute webpage]

Material

Melting

Point

(°F)

Density,

(gm/cm3)

Thermal

Conductivity

(BTU.In/ft2.h.°F)

Yield

Strength

(MPa)

Ultimate

Tensile

Strength

(MPa)

Elastic

Modulus

(GPa)

Mild Steel

2750

7.86

230-360

200 300 200

HSS 7.87 345 485 205

AHSS 7.78 800 1400 208

Stainless

Steel (304)

2600

7.85

110 290 620 203

Aluminum

Alloys

1220

2.71

1644 275 300 70

Magnesium

Alloys

900-

1150

1.77

360-504 120-160 220-230 45

Nickel Base

Alloys

2300 -

2440

8.19

104-135 150 185 203](https://image.slidesharecdn.com/1stprogressreview-230801204009-8a8671fe/85/1st-progress-review-pptx-8-320.jpg)

![Specific strength for various materials

[Ref- https://www.protolabs.com/resources]](https://image.slidesharecdn.com/1stprogressreview-230801204009-8a8671fe/85/1st-progress-review-pptx-9-320.jpg)